-

Headquarters -

403-789 Don Mills Rd, Toronto, Ontario, M3C 1T5

-

Year established -

2013

-

NAICS -

325999 - All other miscellaneous chemical product manufacturing

-

Major expansions -

2018

-

Employees -

14

-

Exports -

US, China, Brazil, Chile

-

Download -

CHAR Technologies Limited

Headquartered in Toronto, Ontario, CHAR Technologies Limited (CHAR) is an innovative cleantech company that specializes in biocarbon fuel development and provides custom equipment for a wide range of industries. CHAR has quickly become a leader in green innovation through its use of Canadian technology to create environmentally sustainable solutions.

Headquartered in Toronto, Ontario, CHAR Technologies Limited (CHAR) is an innovative cleantech company that develops breakthrough, environmentally-friendly, technologies, manufactures industry-leading products, and offers expert consulting services. The firm specializes in biocarbon fuel development and provides custom equipment for a wide range of industries. CHAR has quickly become a leader in Canadian green innovation through its use of Canadian technology to create environmentally-sustainable solutions. In light of the Ontario government’s plan to balance a healthy economy with a healthy environment by encouraging the implementation of innovative energy solutions, CHAR looks well-positioned to continue its rapid growth.

The idea for CHAR’s first product originated from the firm’s Chief Executive Officer, Andrew White, while he was completing his master’s degree in chemical engineering at the University of Toronto. White and his supervisor, Dr. Don. Kirk, toured a farm-based biogas plant and noticed how much by-product was created from producing renewable natural gas. This observation motivated White to co-create CHAR’s first product, SulfaCHAR, with Dr. Kirk in 2009 In April 2016, White took his company public on the TSX Venture Exchange in order to raise additional funds, which allowed CHAR to continue its research and begin developing more products and technologies. In 2018, CHAR acquired The Altech Group to internalize engineering services that it had previously subcontracted and to strengthen the consulting side of the business.

CHAR describes its SulfaCHAR product as being unlike any other gas cleaning technology because it produces absolutely no waste. The product is an absorbent that removes toxic hydrogen sulfide from methane gas in a similar manner to a Brita filter removing contaminants from water. The clean biogas that remains after the hydrogen sulfide is removed can be used for various energy applications. Importantly, after being absorbed into SulfaCHAR, the contaminant is converted into beneficial forms of sulfur, which can be used as a sulfur-rich bio-char fertilizer (e.g., farmers who need more sulfur in their fertilizer often purchase SulfaCHAR).

Currently, CHAR is manufacturing SulfaCHAR at an anaerobic digestion biowaste facility in London, Ontario. CHAR feeds the facility’s waste into its manufacturing cell, which utilizes airlocked heating and is capable of heating up to a temperature of 850 degrees Celsius. By adjusting the temperature and other settings on the manufacturing equipment, CHAR can use different types of feedstock to manufacture SulfaCHAR, or a slight variation of it. The firm is currently researching how to create SulfaCHAR when the feedstock used is wood chips, rather than biosolids.

While creating SulfaCHAR, White realized that a similar process could be used to develop a cost-effective, sustainable fuel to replace coal. This product, Cleanfyre, is a carbon-neutral bio-coal with the same energy potential, ash profile, and chemical composition as coal. Further, there are no refitting costs for customers when they switch from coal to Cleanfyre because it integrates seamlessly into the existing infrastructure. In 2019, Canada’s largest flat roll steel producer, ArcelorMittal Dofasco (AMD), announced that it would conduct an initial 20-tonne trial of Cleanfyre in its blast furnaces. After confirming the product’s effectiveness and ability to meet the strict requirements of the steelmaking industry, AMD will evaluate its implementation of Cleanfyre.

In addition to the manufacturing side of its business, CHAR offers consulting and engineering services through both Altech and CHAR Technologies. Firms across a variety of industries partner with CHAR to identify environmental concerns and proactively design remediation solutions. CHAR has expertise in designing solutions for pollution or regulatory compliance issues within industries that involve air, gas, or water services. Client satisfaction is CHAR’s top priority, which is why all of its innovative solutions aim to be cost-efficient, easy to implement, and designed to reduce or eliminate client risk. For example, an apple cider facility near Peterborough did not have access to municipal utilities, so CHAR designed and manufactured a water treatment system that would clean wastewater well enough for it to be reused.

Rather than engaging in expensive external marketing campaigns, CHAR has increased its customer base through networking and word-of-mouth referrals. White notes that the Canadian Trade Commissioner Service has been especially helpful in organizing introductions. The firm has expanded into various industries around the world, including food, beverage, aerospace, mining, and organics processing. Depending on the location of the project, CHAR may both design and build its environmental solution, or simply outsource the manufacturing portion. For instance, the majority of its projects in North America are designed and manufactured in Ontario. Equipment for a copper mine in Chile was also manufactured in Ontario; however, construction of equipment designed for a corn facility in Brazil began in Ontario and concluded in Brazil. Fortunately, although CHAR has three direct competitors scattered across Canada, they have all agreed that growing the cleantech industry in Canada is more important than directly competing in the current economy.

CHAR has developed positive relationships with multiple government networks and successfully utilized a number of government funding programs. For example, CHAR’s partnership with AMD was orchestrated by Ontario Centres of Excellence. In addition, CHAR received a grant for its Cleanfyre production from the Government of Ontario through the Low Carbon Innovation Fund. The firm has also utilized the Industrial Research Assistance Program for some of its research projects. CHAR’s London facility was supported by the SD Natural Gas Fund, a collaboration between Sustainable Development Technology Canada and the Canadian Gas Association. For early-stage research on new ideas, CHAR has experienced success in collaborating with several nearby educational institutions on one-off projects, while the University of Toronto, Western University, and Guelph University are consistent research partners of the firm.

Looking forward, CHAR plans to continue expanding by offering new services and products, as well as entering new markets. White believes there is a significant opportunity for growth in both the North American and Latin American regions. The firm’s first priority is to commercialize its manufacturing cells for SulfaCHAR and Cleanfyre so that the cells can be installed on-site for any customer. CHAR is also researching the possibility of utilizing the gas by-product created by its manufacturing process. Another mid-term goal is to design larger manufacturing cells that can be used by bigger firms who want to use less coal in their processes. To spur this growth, White recognizes that he will have to expand his current workforce of 14 employees. Although a strong technical academic background is key, White is looking for individuals who are also willing to learn more hands-on skills for working with equipment. Most importantly, all employees must demonstrate a genuine passion for environmental control and protection, in line with CHAR’s core values.

For more information about CHAR Technologies Limited, visit their website.

Published: December 9, 2019

Timberland Equipment

Timberland Equipment is a global leader in the integrated design, manufacture and support of engineered winches, hoists, sheaves, derricks and tensioning equipment for the world’s most challenging infrastructure and capital equipment projects.

Electronic Craftsmen

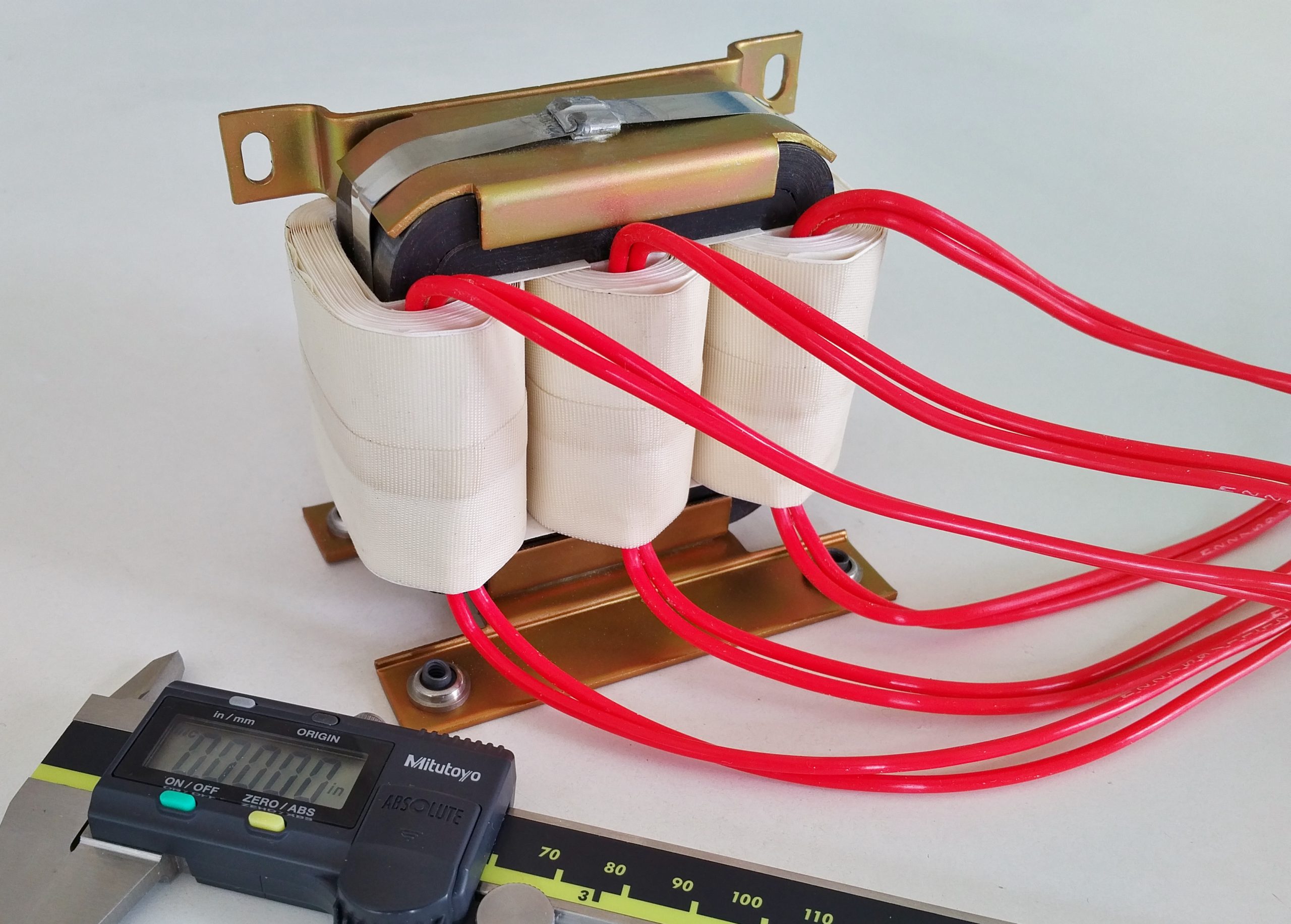

Electronic Craftsmen is a custom designer and manufacturer of specialty transformers, inductors, chokes, and reactors for use in power electronics applications.

CMI Heavy Industries

CMI Heavy Industries is a leading provider of heavy fabricated, forged and cast machined components and assemblies.

SmartCone Technologies Inc.

SmartCone Technologies Inc. is a private company that produces Internet of Things (IoT) – based safety and monitory solutions for a variety of industries. Its main product, the SmartCone, is a deployable sensor device that collects sensor data, analyzes it using advanced computing power and software, and uses the information it learns to keep people safe in vulnerable and hazardous areas. Some areas where SmartCones are currently being utilized are in bike lane safety, construction site safety, and incident management for transportation agencies.

FreePoint Technologies

FreePoint Technologies (FreePoint) is a technology firm located in London, Ontario. Established in 2013, FreePoint helps industrial and manufacturing firms join the Industrial Internet of Things (IIOT) revolution. They do this with their unique, “machine wearable” technology that connects machinery to the cloud, allowing for simple collection and analysis of data on existing machinery.