-

Headquarters -

425 Glendale Avenue, St. Catharines, ON, L2P 3Y1

-

Year established -

1922

-

NAICS -

332710 - Machine shops

-

Major expansions -

N/A

-

Employees -

48

-

Exports -

US

-

Download -

CMI Heavy Industries

CMI Heavy Industries is a leading provider of heavy fabricated, forged and cast machined components and assemblies.

Every day, we rely on products that come from manufacturing facilities, including those from industries like steel and iron, oil and gas, power generation, pulp and paper, and mining. These manufacturers, in turn, rely on heavy equipment firms like CMI Heavy Industries (CMI), a Canadian manufacturer of heavy machining equipment. CMI’s state-of-the-art manufacturing facility (located in St. Catharines, Ontario) and sales offices across the United States are overseen by four brothers: Shawn, David, Brian, and Richard Rapone.

CMI’s focus lies in heavy industry and large manufacturing. The business involves low-volume, custom-engineered manufacturing of components for steel mills, pulp and paper mills, oil and gas operations, and nuclear power plants. Products weigh anywhere from 500 kilograms (kg) to 80,000 kg. The company is thriving, with a growth rate of 450 per cent since 2009. The majority of its sales are in machined components, with the remainder in fabricating and assembly services. Thirty per cent of CMI’s exports go directly to the United States; however, much of the product is then re-shipped to Europe and Asia by its customers. CMI maintains its competitive edge through investment in high-quality equipment and extensive knowledge of the industry.

Having worked at CMI since the 1920s, Pat Rapone bought a share of the company in 1986, working his way up to become the sole owner in 2005. Pat’s sons, Shawn, David, Ernie, and Richard, became involved with CMI at a young age.

“We pretty much started off with sweeping the floors at the plant when we were 13 or 14,” said Shawn Rapone, part-owner and controller of the company today.

While in high school, Shawn and his brothers received special permission to start their apprenticeships in machining at Niagara College early, and were machinists at CMI by the age of 16–17. Shawn went on to study mechanical engineering at Niagara College and then earned a degree in business administration at Brock University. His brothers studied mechanical engineering at McMaster, and electrical engineering and marketing at Niagara College. These qualifications align perfectly with the work the Rapone brothers do at CMI today. In 2005, while in his second year of university, Shawn was already managing the company’s finances. Immersed in the business since their childhood, and equipped with the right education, the four Rapone brothers had skills and experience far beyond their years when they acquired the company from their father in 2010.

Most of CMI’s competitors are owned and managed by people much older than the Rapones. Yet what the brothers lack in age they make up for in knowledge and experience. They know the business in and out because they have worked in most departments in the company, ranging from machining and welding to financial planning and pricing. This unique combination of industry experience and education distinguishes CMI from its competitors. In contrast to the traditional route of entering an industry with little work experience following a post-secondary degree, the Rapones understood the needs of the firm and planned their educations accordingly.

CMI’s customers and employees also contribute to the company’s success. The firm strategically focuses on specific types of customers that they meet through trade shows and face-to-face interactions, and their dedicated employees create the products that meet those customers’ needs. The majority of the employees are machinists, millwrights, and welders from college programs and apprenticeships. The company typically has eight to twelve apprentices at a time sponsored from surrounding colleges. CMI employees teach and train the students over a three-year period. Apart from apprenticeship experience, many graduates from Niagara College, Mohawk College, the University of Waterloo, and Brock University come to CMI with qualifications in business, engineering, industrial machinist and welding.

According to Shawn Rapone, hiring workers with the right skills in today’s job market is difficult. Employees operate expensive machines—some cost over $1 million USD—that run for three shifts a day. Rapone is interested in changing the narrative around Ontario’s manufacturing sector, as well as the negative perception of careers in manufacturing among young people. Although the work does not always fall within a typical 9-to-5 work day, students with advanced math skills and an interest in engaging, hands-on work can find a career as a machinist very rewarding. By taking advantage of government offerings (Canada Job Grants), CMI hopes to continue expanding relationships with local colleges to expose students to promising careers in manufacturing.

With its annual growth target of 10 to 20 per cent, Shawn Rapone says CMI will “stay on the top of the game by focusing on efficiency.” Matching the latest technologies with the right workers will allow the company to use its machinery more efficiently without sacrificing quality: a sound recipe for continued success.

For more information about CMI Heavy Industries, visit their website.

Published: July 26, 2016

Timberland Equipment

Timberland Equipment is a global leader in the integrated design, manufacture and support of engineered winches, hoists, sheaves, derricks and tensioning equipment for the world’s most challenging infrastructure and capital equipment projects.

London Mat Industries

London Mat Industries Ltd (London Mat) is the manufacturer of the world famous “MATEX” Treadle Switches, used on Buses, Trains and Trams for door safety, opening and passenger counting.

Industrial Parts Manufacturing

Industrial Parts Manufacturing specializes in CNC machining, general machining, welding and fabricating.

SmartCone Technologies Inc.

SmartCone Technologies Inc. is a private company that produces Internet of Things (IoT) – based safety and monitory solutions for a variety of industries. Its main product, the SmartCone, is a deployable sensor device that collects sensor data, analyzes it using advanced computing power and software, and uses the information it learns to keep people safe in vulnerable and hazardous areas. Some areas where SmartCones are currently being utilized are in bike lane safety, construction site safety, and incident management for transportation agencies.

Electronic Craftsmen

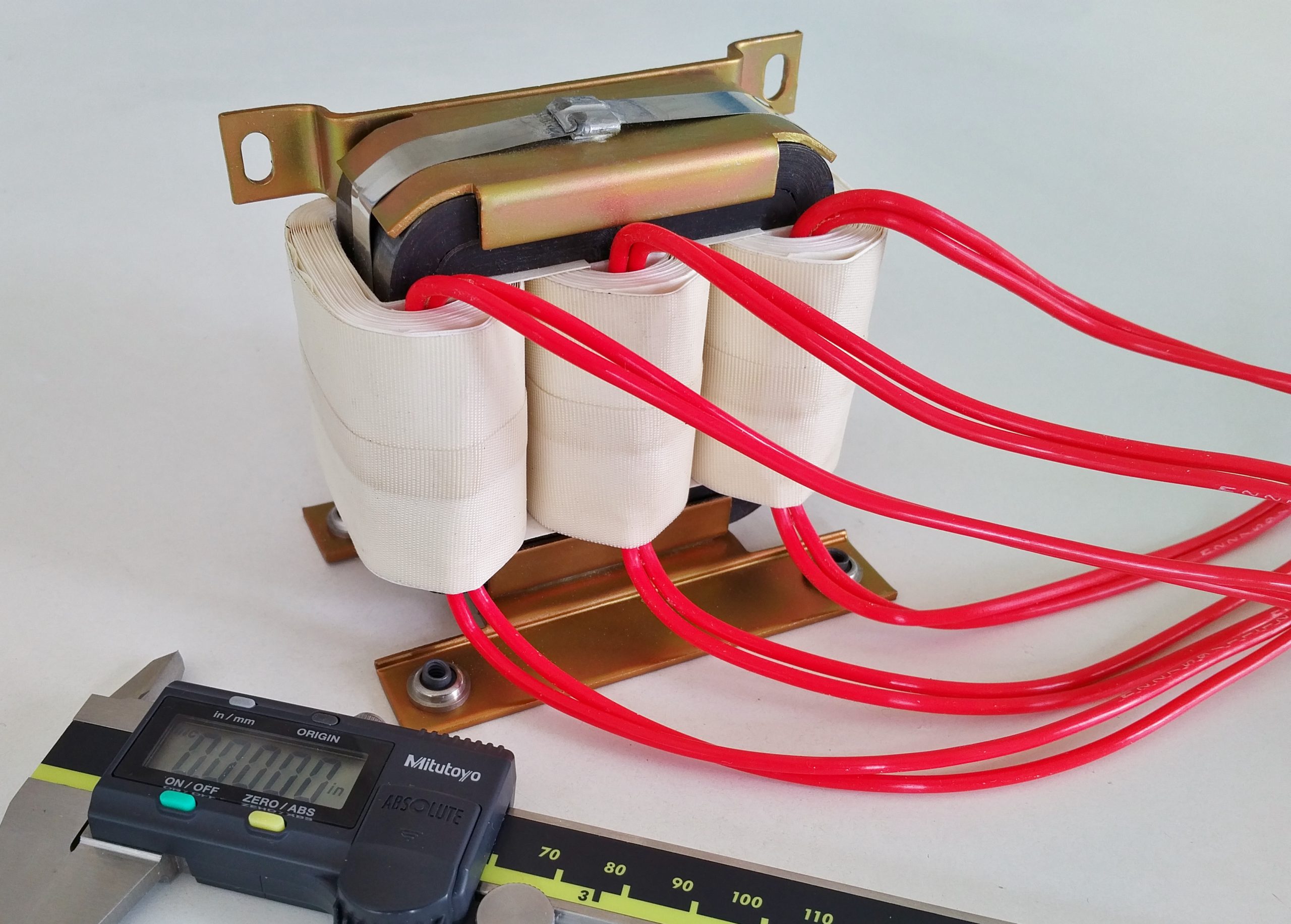

Electronic Craftsmen is a custom designer and manufacturer of specialty transformers, inductors, chokes, and reactors for use in power electronics applications.