-

Headquarters -

20 Stewart Rd, Collingwood, ON L9Y 4V4

-

Year established -

1983

-

NAICS -

334410 - Semiconductor and other electronic component manufacturing

-

Major expansions -

2021

-

Employees -

45

-

Exports -

U.S.

-

Download -

Sensor Technology Ltd.

The marine, fishery, energy, and security and defence industries depend on advanced technology to sense underwater activity.

Electronic sensors with ceramic components built by Sensor Technology Ltd. are a critical component in this technology. The Collingwood business turned the original Blue Mountain Pottery company into a state-of-the-art technology manufacturing facility that enables oceanic research, marine life preservation, energy exploration, and security.

Sensor Technology Ltd.’s success in the oceanic industry is fueled by the growing interest in mapping the undiscovered ocean floor. Marine applications for the company’s sensors include sonars that take images of the subaquatic terrain, measure the depth of water (referred to as bathymetry), and measure the position of objects under water relative to other points. The company also supplies ceramic components for telecommunications and marine life monitoring devices. Its products help find everything from shipwrecks to pockets of oil and gas.

When Sensor Technology Ltd. launched, funding from the United States Department of the Navy’s Office of Naval Research was available to smaller companies to supply products for underwater use. This funding helped Prasad and his wife, Shashi, build the company.

When the Blue Mountain Pottery company, established in 1947, decided to reinvent the company in 1983, it brought in Eswar Prasad. He was the perfect fit to build Sensor Technology Ltd., with a PhD in piezoelectric ceramics and experience in high-tech ceramics. Piezoelectricity is the electric charge that accumulates in solid materials. Sensor Technology Ltd. uses the ceramic manufacturing capabilities of the original pottery-making facility as a basis to build electronic sensor components.

When Sensor Technology Ltd. launched, funding from the United States Department of the Navy’s Office of Naval Research was available to smaller companies to supply products for underwater use. This funding helped Prasad and his wife, Shashi, build the company. They made Collingwood their home and raised their daughter, Niru, in the community. In 2009, they struck a deal to sell Sensor Technology Ltd. to an oil and gas company and brought Niru in to serve as an interim operations manager and oversee the integration of Sensor Technology Ltd. with the buyer. She had earned a bachelor’s degree in geophysics and a master’s in engineering before joining the company. When the sale fell through, Niru remained with the company. In 2011, she bought her parents’ shares and took over as president and chief executive officer.

Sensor Technology Ltd. is one of only five companies in the world that manufactures ceramic sensor components, and only one of three that works with customers through to the assembly phase.

Niru Somayajula is well-equipped to run the company. She learned the business working in production before becoming president and CEO. Her father nurtured her interest in developing technical skills. Her mother, who holds a master’s degree in economics, taught her that “the person who manages the finances manages the company.” Niru is happy to have come full circle, living and working in Collingwood after exploring and doing internships in countries around the world.

Sensor Technology Ltd. is one of only five companies in the world that manufactures ceramic sensor components, and only one of three that works with customers through to the assembly phase. Its customers are divers with unique needs. Sensors that are used in the security and defence industry for life saving missions must be accurate and reliable. Functions like port security, mine detection and diver location detection require a high level of precision and many of its products are used in remote locations with extreme changes in temperature.

Early in the sales process, customers are asked about the pressure that the sensor will be used at so the company can replicate the environment in which new components are tested. Since Georgian Bay is frozen for weeks each year, Sensor Technology Ltd. has built indoor pools to allow for year-round testing.

Raw materials are sourced in Canada. This is a requirement for federal government contracts, and a preference for the company. It is willing to pay a premium for materials because customers understand the risks of compromising. Somayajula hopes buying local creates a snowball effect where strong supplier relationships lead to new referrals and opportunities for the company.

The manufacturing process for piezo ceramics is complex. Since each piece is unique and averages about 20 steps to make, Somayajula suggests “there are 20 ways to get it wrong.” Automation companies in Collingwood and Barrie have helped the company explore opportunities to ramp up production. Employees are specialized in specific processes including making powder, molding, machining, and testing, although some cross training is offered to the team of about 50 people.

In addition to skilled resources, Collingwood also offers cheaper real estate costs. Sensor Technology Ltd. has expanded to three manufacturing facilities in Collingwood as well as adding a sales and production presence in Nova Scotia, closer to its naval customer base.

Sensor Technology Ltd.’s employees enjoy a high quality of life in Collingwood. The company has no difficulty recruiting and retaining good people. Most employees have been with the company for over 20 years, enjoying the opportunity to do interesting work and live in an active four seasons community. Newer talent was made available to the company during the Covid-19 pandemic, when people with a broad range of skillsets chose to move out of larger cities and settle in Collingwood.

In addition to skilled resources, Collingwood also offers cheaper real estate costs. Sensor Technology Ltd. has expanded to three manufacturing facilities in Collingwood as well as adding a sales and production presence in Nova Scotia, closer to its naval customer base. The company has invested in equipment upgrades in Collingwood to meet 30 per cent year-over-year demand for the past three years.

Sensor Technology Ltd. is a member of Canada’s Ocean Supercluster, an industry-led organization that brings together companies across Canada from the fishery, aquaculture, bioresources, offshore resources, marine renewables, defence, shipping, and ocean technology industries. Membership in the cluster gives it exposure to innovative projects with industry, research, not-for-profit, investor, and government funding partners. One such project was announced in March 2021, in partnership with another cluster member, Kraken Robotics. The Autonomous COMPASS (Compact Passive Acoustic Sensing System) Project will develop a portable, embedded acoustic device allowing data to be collected and analyzed in real time, onboard an untethered autonomous underwater vehicle. Data will be used in defence, research, marine mammal protection and energy exploration. The company has supplied sensors for drones that are used to reduce whale strikes in the shipping industry. The COMPASS project is the first of its kind to take autonomous monitoring under water.

Customization, knowledge and innovation are Sensor Technology Ltd.’s main differentiators. Its customers are unique, and so is the company, transforming a traditional manufacturing business into a high-tech supplier to the oceanic exploration industry.

Published: October 14, 2021

OES

What is one thing that the Toronto Raptors, the Buffalo Bills, the Los Angeles Dodgers, and the Pittsburgh Penguins all have in common?

Bluewrist Robot & Vision Solutions

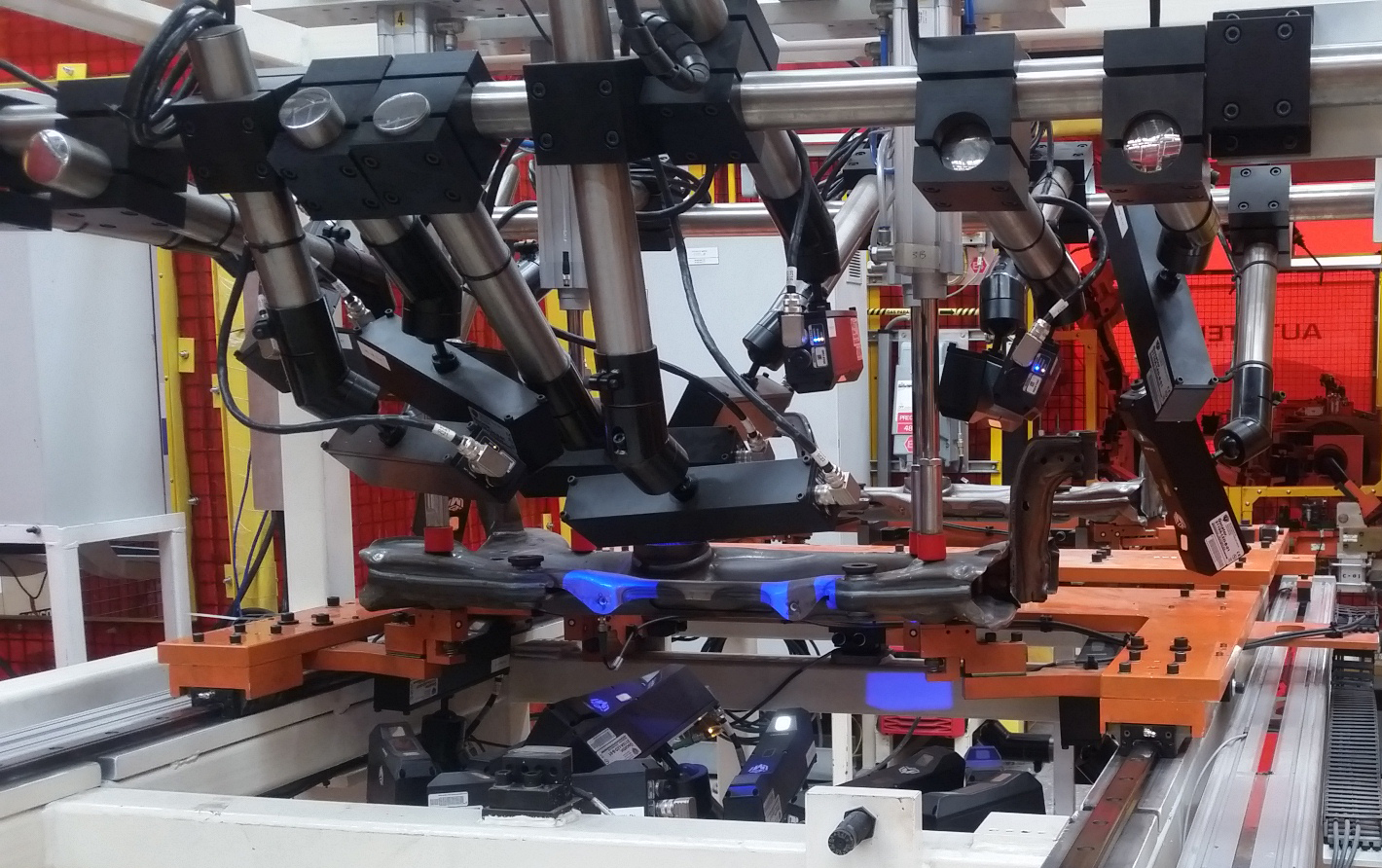

Bluewrist Robot & Vision Solutions designs and develops innovative industrial automation solutions in the fields of robot guidance and 3D machine vision.

RBR Ltd.

RBR designs and manufactures innovative oceanographic instruments that satisfy customer budgets and applications. The company offers sensors capable of tracking various water parameters, data loggers, and a variety of accessories for its products.

FreePoint Technologies

FreePoint Technologies (FreePoint) is a technology firm located in London, Ontario. Established in 2013, FreePoint helps industrial and manufacturing firms join the Industrial Internet of Things (IIOT) revolution. They do this with their unique, “machine wearable” technology that connects machinery to the cloud, allowing for simple collection and analysis of data on existing machinery.