-

Headquarters -

4056 Blakie Rd, London, ON, N6L 1P7

-

Year established -

1980

-

NAICS -

335990 - All other electrical equipment and component manufacturing

-

Major expansions -

1988, 1999, 2008, 2017

-

Employees -

90

-

Exports -

United States, Mexico, South America, Europe, Asia

-

Download -

OES

What is one thing that the Toronto Raptors, the Buffalo Bills, the Los Angeles Dodgers, and the Pittsburgh Penguins all have in common?

Their home venues rely on scoreboards, timing clocks, or device operating systems developed by the same Canadian manufacturer: OES. In fact, OES has about 40 per cent market share for these products in the NBA, NHL, NFL, and CFL. It is one of the only two scoreboard companies approved to provide scoring and timing to these professional leagues.

OES products are also installed at dozens of amateur and school sports venues across North America. “We want to make sure the youngest of athletes feels like a professional,” says Julie Neufeld, the company’s Marketing Manager.

As a medium-sized company, OES had to learn how to compete with larger companies and with manufacturers based in lower-cost regions. The answer was to focus on making niche products, continuously improving quality, fostering in-house innovation, and investing in the newest technologies.

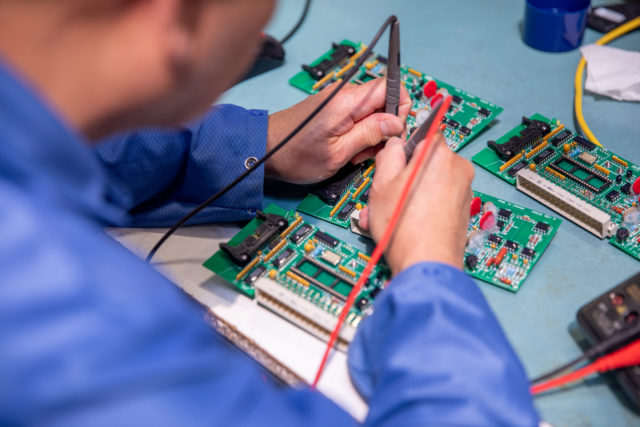

Scoreboards, timing clocks, and other ancillary products that serve the sports industry make up only about one half of OES’ business. Founded in 1980, OES is primarily an electronics manufacturing services (EMS) company based in London. With 90 employees, the company assists its customers in designing, developing, prototyping, and manufacturing electronic components and products. Today, OES exports 60 per cent of its products, mainly to the United States, but also to Mexico, South America, Europe and Asia.

“Our engineers are our biggest competitive advantage,” says Jeff Stewart, the company’s CEO. “Many of our competitors can only build things based on customer specs but OES engineers assist customers in every step of electronics manufacturing.” That competitive advantage attracted companies like Trojan Technologies, Stryker Corporation, and General Dynamics to work with OES.

As a medium-sized company, OES had to learn how to compete with larger companies and with manufacturers based in lower-cost regions. The answer was to focus on making niche products, continuously improving quality, fostering in-house innovation, and investing in the newest technologies. Combined with the company’s extensive expertise in building printed circuit boards, electronic components and devices, that strategic focus allowed OES to enter niche markets where it could compete strongly.

Many of the innovations that provide OES with a competitive advantage originated from employees’ desire to make products that enhanced the customer experience.

One of the earliest niche products OES built under its own brand were the timing clocks used by flower auction houses in the Netherlands. Then, ahead of the 1994 CHL playoffs, the London Knights asked the company to upgrade its scoreboard with LED digits. That marked the beginning of OES’ venture into the scoreboard market.

Innovation helped OES differentiate itself from other companies making scoreboards. Many of the innovations that provide OES with a competitive advantage originated from employees’ desire to make products that enhanced the customer experience. Traditional scoreboards at football and baseball fields used red, amber or orange digits and suffered from low visibility during daytime. To solve that issue, OES made scoreboards with bright white LED digits. While they cost more initially, increased sales and happier customers justified the move.

More recently, OES disrupted the scoreboard market with another innovation. The company managed to achieve multiple colors appearing from the same set of LED digits used in a scoreboard. Taking that hardware innovation one step further, OES built complementary software for their new digit technology, aptly named ColorCast. ColorCast and ColorCast Pro offers customers the ability to select virtually any color combination imaginable, change digit colors during a game, and activate dynamic in-game features based on the current state of play. That would not have been possible if OES had not recognized the growing importance of software in the market and invested in its in-house software development capabilities.

Thanks to these innovations and the company’s reputation as a supplier of high quality scoring products, OES scoreboards, video displays, timing solutions and scoreboard control systems are used in stadiums and professional sports venues across North America. Recent projects include SoFi Stadium in Los Angeles (home of the NFL’s Rams and Chargers) and Allegiant Stadium near Las Vegas (home of the NFL’s Raiders). OES is also the official scoring and timing supplier of the Niagara 2022 Canada Summer Games.

Seeing an opportunity to grow its footprint in this niche market, OES continued launching new products to assist automakers, wire harness manufacturers, and machine builders with quality control.

OES stepped into another niche market when several global automakers with plants in southern Ontario asked for the company’s help to solve high defect rates in wire harnesses. Wire harness defects led to many problems like intermittent connections in correct wire/terminal combinations and open circuits. To address the issue, OES engineers developed sensing and detecting devices that automatically measure the ‘crimp force’ applied during wire crimping, a process that determines the final quality of wire harnesses.

Seeing an opportunity to grow its footprint in this niche market, OES continued launching new products to assist automakers, wire harness manufacturers, and machine builders with quality control. The company obtained 16 patents along the way to protect its innovations. Sales offices were opened in China, Switzerland, and Mexico. What started as a business to assist the needs of local automotive manufacturers soon turned into a global operation. Ford, General Motors, Mercedes, and Tesla became OES’ customers.

...with recent challenges in the electronics supply chain, a lot of companies are looking at onshoring or at least making back-up plans.

While niche products and innovations provide OES with opportunities to diversify its markets and grow, electronics contract manufacturing still lies at the heart of the company’s business. Stewart sees this business as the driving force for OES’ future growth, noting that “with recent challenges in the electronics supply chain, a lot of companies are looking at onshoring or at least making back-up plans.”

According to Stewart, OES is well-positioned to answer the growing demand. The company has invested in the newest technologies, such as automated printed circuit board surface mount assembly systems built by ASM, a former subsidiary of Siemens. Sorting through thousands of raw materials is handled by a computerized vertical lift management system. An enterprise resource planning (ERP) system facilitates faster and more accurate decision making. Moreover, OES continuously improves efficiency in line with Lean manufacturing principles. All of these factors contribute to OES’ confidence that it can manufacture electronics profitably in North America.

One of the key opportunities for OES is to leverage its expertise in electronics manufacturing to help companies bring their innovative ideas to market. A dedicated business development team actively identifies technology firms with innovative ideas to form new partnerships. With its comprehensive in-house capabilities, OES can take any idea; design, engineer, and build prototypes; source all the components, and help companies get to market faster. That makes OES a facilitator of wider innovation within Ontario’s advanced manufacturing and technology ecosystem.

To provide such comprehensive services to its customers, OES needs to have a highly-capable team. Currently, about half of the company’s 90 employees work in production roles. The other half work in engineering and administrative roles. When it comes to recruitment, being in London is OES’ biggest advantage. Western University and Fanshawe College provide a steady supply of high-quality talent for the company.

However, because it can be challenging to hire people quickly at times of fast growth, OES follows a unique hiring strategy. The company is always recruiting, even when there are no open positions available. Managers keep a list of individuals who they know and would like to get on the team. They talk to them regularly. When there is an opening, instead of going to a recruiter, the company reaches out to them directly.

Besides reaching business objectives, OES also puts emphasis on community engagement. The company lends its support to younger, amateur athletes across North America through various partnerships with volunteer organizations. It supports many charitable organizations like the London Food Bank and World Vision Canada. These activities also bring OES employees together.

Looking forward, OES sees two key growth opportunities. First, it anticipates wire harness quality to become even more important for automakers as they transition into making electric vehicles. That means potentially higher demand for OES’ quality assessment devices. Second, due to Covid-19 and several recent disruptions in electronics supply chains, more companies are looking to onshore electronics manufacturing. Medical device manufacturers are one example. OES feels confident that it will establish new partnerships to support these efforts. Specifically, there is a significant opportunity for the company to enter medical device manufacturing, by capitalizing on its experience making healthcare electronics.

Electronics manufacturing is known to be a highly-competitive industry globally. OES provides a testament that an Ontario company in this sector can compete internationally with state of the art technologies, a highly-skilled workforce, and a culture driven by innovation.

Published: October 5, 2021

Ross Video

Ross Video Limited is an Emmy-winning designer and manufacturer of live video broadcast equipment. Founded in 1974 by its namesake, John Ross, the firm has experienced dramatic growth in the past several decades and now boasts a workforce of almost 1,000 employees across 13 global offices.

Mircom Group

Building on the past, planning for the future, while reacting to today’s challenges are keys to Mircom’s success.

Christie Digital

Christie Digital is a global visual, audio and collaboration solutions company offering diverse solutions for business, entertainment and industry.

Quantum5X

Quantum5X (Q5X) is a privately owned corporation that specializes in wireless solutions for challenging audio problems in sports, broadcast and entertainment.