-

Headquarters -

1030 Fountain Street North Cambridge, Ontario N3H 4R7

-

Year established -

1983

-

NAICS -

333519 - Other metalworking machinery manufacturing

-

Major expansions -

-

Employees -

30

-

Exports -

USA, Mexico, Europe

-

Download -

RACER Machinery International

When Siemens North America needed a partner to meet very specific needs for its first digital twin initiative, they chose RACER Machinery International.

RACER’s Chief Operating Officer Alex Vojinovich describes this opportunity as “validation of years of RACER providing quality machinery, rich in technical developments, to the market.” A year later, Siemens is promoting the success of the project, citing up to 30 per cent faster time to market and up to 25 per cent higher machine productivity, an impressive result when a huge multinational company collaborates with a 30 person Ontario manufacturer.

RACER Machinery International has evolved from a small equipment repair business to a custom manufacturer of engine lathes and machinery for machine components for Thyssenkrupp GM, Magna, Martinrea, Toyota, General Dynamics, US and Canadian Defence and others. However, its success was no accident. It is the result of a founding family combining a traditional quality-centered approach with a willingness to embrace innovative technologies like additive manufacturing and digital twins.

When first founded by Don Zoran Vojinovich in 1983 as Progress Machine in Cambridge, the company...operated as an engine lathe and machine repair shop, building and retrofitting Standard Modern™ Lathes.

When first founded by Don Zoran Vojinovich in 1983 as Progress Machine in Cambridge, the company focused on enabling customers to maximize the functional lives of their lathes. At the time, it operated as an engine lathe and machine repair shop, building and retrofitting Standard Modern™ Lathes. Standard Modern was originally founded in Windsor in 1931 and became an industry standard for manufacturers and training facilities around the world.

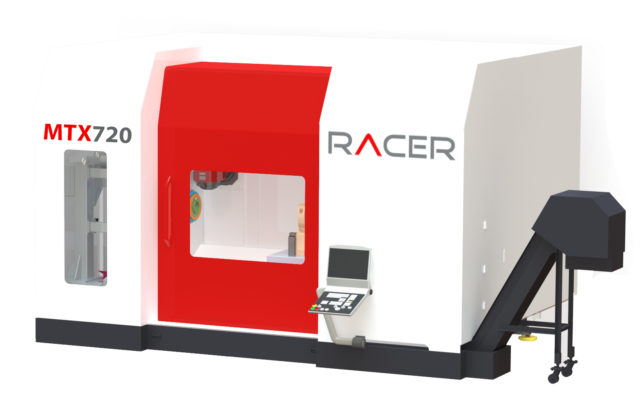

In 1990, Progress Machine became Racer Machinery Company and the company continued servicing lathes as well as introducing its own line of branded machinery. Having built and repaired the Standard Modern brand in the 1980s, the company seized the opportunity to buy the Standard Modern Lathe company in 2014 and move it from its location in Pennsylvania back to Ontario. Machine tools are stationary power-driven machines that shape or form metal parts. Engine lathes change the size, shape or finish of a revolving metal piece using various cutting tools. Today, RACER builds machine tools under the Phantom Machine Technology brand, manual engine Standard Modern lathes, and saws bearing the E-R Maier label. The company provides technical support in addition to building these signature products.

According to Alex, much of RACER’s success can be attributed to its Cambridge location. Being close to Toronto, London, Windsor, and the U.S. border gives it access to markets, automotive and defense manufacturers.

Since its founding, RACER has expanded to larger facilities a total of five times, always in Cambridge. Today, the company is run by Don and his sons Alex and Igor Vojinovich, Chief Operating Officer and Chief Administrative Officer respectively. According to Alex, much of RACER’s success can be attributed to its Cambridge location. Being close to Toronto, London, Windsor, and the U.S. border gives it access to markets, automotive and defence manufacturers.

Cambridge provides RACER with a robust labour pool. However, like many manufacturers, accessing skilled workers is becoming increasingly challenging for RACER as the workforce ages. While CNC technology is taught in the trades schools, the company encourages more schools to update the curriculum to keep up with the industry’s software and technological advances. As a corporate sponsor of the McMaster Manufacturing Research Institute (MMRI), led by Dr. Stephen Veldhuis, RACER helped develop specialized courses that are offered to manufacturers by the Institute. Participants in MMRI’s training programs come from various stages in their careers, and can earn certificates in Process, Materials, or in Industry 4.0.

Regardless of an applicant’s formal training, RACER describes its recruiting approach as “hiring for common sense”. If someone demonstrates they have basic skills, RACER will invest in the training required to close any gaps. Alignment with the company’s vision is as important as a skills fit. Teamwork is one of the four pillars of RACER’s vision, along with integrity, passion and excellence. Employee ideas are encouraged and the benefit of a variety of views is realized.

The company founder’s commitment to quality and customer service lives on, and RACER is still known for making high quality products despite the influx of cheaper alternatives from lower cost regions. As Alex puts it, “We compete with China on quality. Ours are not cheap lathes.” Chinese competitors offer lower-cost, off-the-shelf solutions for customers less concerned with quality and durability. RACER works hard to reinforce the message that lathes are complex pieces of equipment that can be customized to meet very specific requirements. Made in Canada, by Canadian-skilled workers, using Canadian materials is RACER’s competitive advantage, offering a 20-year parts and service guarantee on its products.

In September of 2020, Siemens chose RACER to develop CNC technology that will improve customer productivity through the use of digital twins.

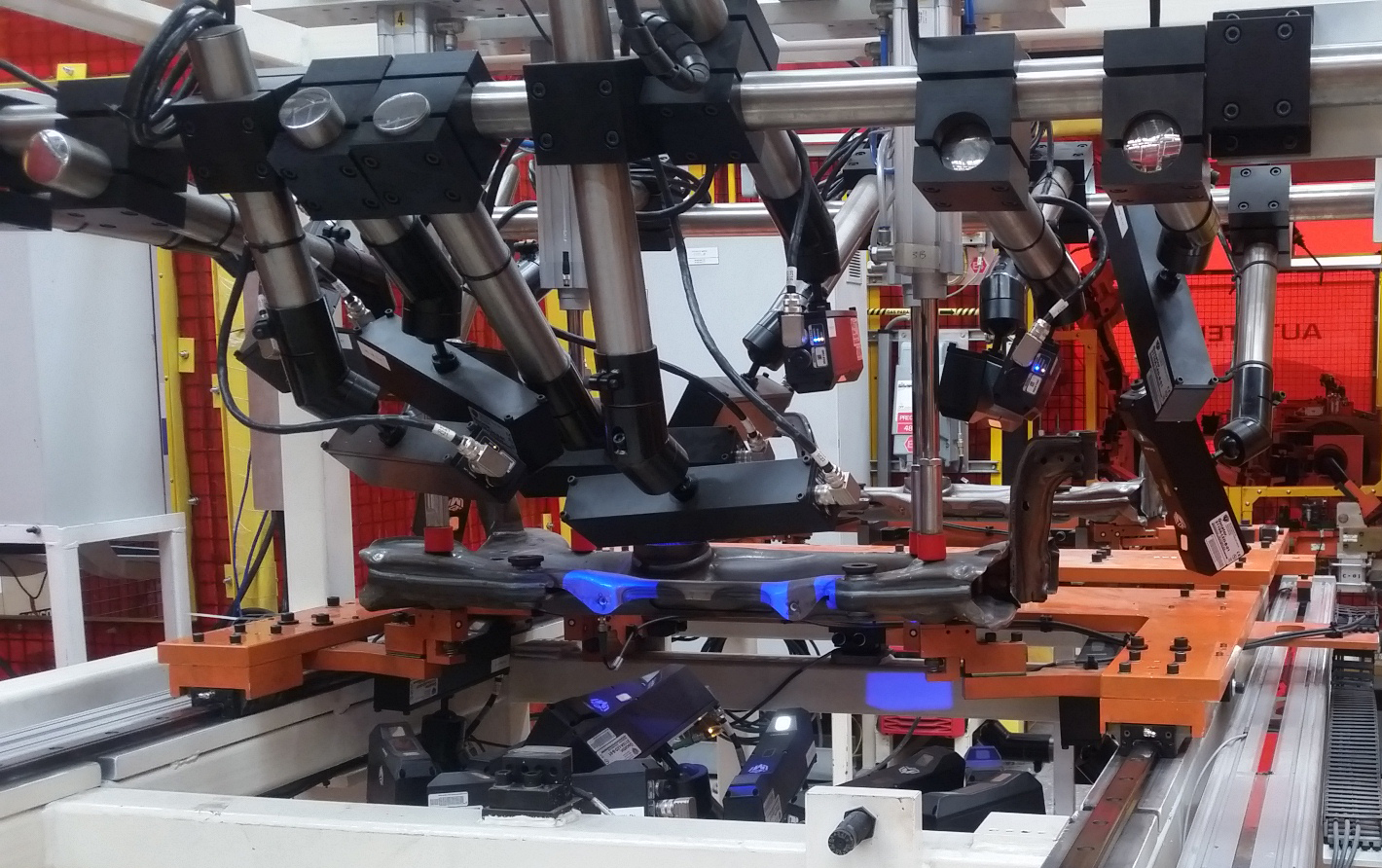

In addition to the proven machine tool, lathe and saw products, RACER is experiencing growth on the services side of the business as newer technology enables behind the scenes enhancements in its customers’ manufacturing processes. In September of 2020, Siemens, the long-time leading manufacturer of CNC controls, has selected RACER Machinery International, Inc. to be part of its North American “Field Experience” phase for its new revolutionary SINUMERIK ONE, the first digital native CNC. A digital twin is a computer replica of a real-world product which allows the customer to test new systems prior to manufacturing and ensuring the most productive methods are in place. RACER is piloting the new technology on all of its metal cutting platforms.

RACER provides the highest level of training, service, and support in the industry. Training includes three days of programming/applications training at a local university. Additionally, the customer’s maintenance personnel are invited for the last week of assembly and run-off at our plant. After installation at the customer’s facility, RACER’s service personnel and engineers work with three groups of customer personnel, namely, maintenance, operators and high-level engineers to ensure understanding of the equipment to make in-house support as effective as possible. Additionally, a key component in RACER’s performance is the “Box in box design”, which brings to the final customer superior damping characteristics, higher speed, and higher precision feed.

In addition to its Canadian and American sales, RACER also exports to Mexico, Europe, and other parts of the world. While selling expensive machine products to manufacturers in the low-cost region of Mexico seems counterintuitive, RACER saw an opportunity to help Mexican suppliers secure and retain OEM contracts by meeting rising quality standards. This risk was offset by support from EDC which provided insurance and advice that protected the company from non-paying customers. The European market, however, remains challenging for growth as they are more confident in their own capabilities and less open to what RACER and Ontario can provide.

When Don Zoran Vojinovich started Progress Machines in 1983, the focus of the company was enabling customers to maximize the functional lives of their lathes by servicing and rebuilding them. Nearly 40 years later, RACER Machinery International is a much different company with three key brands, advanced solutions and technologies, and a growing international footprint. However, they are still enabling the success of their customers and the innovation that has made Ontario the manufacturing hub it is today.

Published: June 15, 2021

Proto3000

Based in Vaughan, Proto3000’s design, additive manufacturing, and metrology technologies help customers solve complex engineering and manufacturing challenges, resulting in shorter cycle times, more flexible supply chains, faster prototyping and more efficient production.

Axiom Group Inc.

Axiom Group Inc. has a long history of forward-thinking and technological innovation. When Industry 4.0 presented opportunities to further improve operations, they were ready.

Bluewrist Robot & Vision Solutions

Bluewrist Robot & Vision Solutions designs and develops innovative industrial automation solutions in the fields of robot guidance and 3D machine vision.

Advanced Design Solutions

Advanced Design Solutions Inc. is a designer and manufacturer of material-handling containers, racks, bins, and dunnage. The firm specializes in the production of steel shipping rack and assemblies that use structural steel components such as tubing, channels, angles, and flat bar.

Shimco

Located in Cambridge, ON, Shimco has served the aerospace, defense, space, industrial and other industries worldwide with precision manufactured parts, laminated and edgebond shims, tapers and spacers for over 25 years. Shimco offers a tradition of Innovation, Precision, and Execution, providing solutions that conform to exacting international and customer-specific standards.