-

Headquarters -

2767 Brighton Rd, Oakville, ON, L6H 6J4

-

Year established -

1995

-

NAICS -

333248 - All other industrial machinery manufacturing

-

Major expansions -

2007, 2010

-

Employees -

125

-

Exports -

United States, Argentina, South Korea, Japan, South Africa

-

Download -

Promation

Ontario’s automation and robotics industry plays a vital role in the expansion, scale up, and technological advancement of the manufacturing sector. Promation demonstrates that the industry can drive initiatives, collaborations, and innovations that have an even broader impact.

Promation employees moved at light speed when they learned early in the COVID-19 pandemic that Canada was on the verge of a ventilator shortage. Collaborating with researchers from the University Health Network, the University of Toronto, and the Mackenzie Innovation Institute, they built two low-cost ventilator prototypes within two weeks. Designs were made public so that the ventilator could be mass-manufactured wherever conventional ventilators were scarce.

The ventilator project “truly reflects who the company is,” says Alex Sakuta, Promation’s Director of Research and Development. Indeed, it is only one example of how Promation excels at adapting to changing market needs quickly and building impactful collaborations that have wider benefits for the society.

Founded in 1995, Promation is a manufacturer and an integrator of custom automation and robotics systems. Initially, the company served the automotive industry. Over time, it has pivoted into serving other industries, such as nuclear power generation, radiopharmaceuticals, and personal protective equipment (PPE) manufacturing. This was made possible by the company’s ability to transfer its expertise across different industries at strategic times. Today, the company employs 130 people at its facility in Oakville and has exported its products to the United States, South Korea, Japan, Germany, South Africa, and Argentina.

Automation companies like Promation not only facilitate the expansion and scale-up of Canada’s manufacturing sector but also act as drivers for broader initiatives and collaboration

According to the company’s president, Darryl Spector, “automation companies like Promation not only facilitate the expansion and scale-up of Canada’s manufacturing sector but also act as drivers for broader initiatives and collaboration.” Guided by that vision, Promation recently embarked on a project to achieve exactly that. The project aims to build up domestic medical gown production capabilities to provide an alternative to international sourcing. Promation’s initial partners in the project were Harbour Technologies and Wuxly Movement. The company then brought Superior Technologies, an Indigenous-owned company, into the consortium. By doing so, it hopes to facilitate reconciliation with First Nations communities while helping to build a more independent domestic supply chain for PPE.

The project is a genuine collaboration. Harbour Technologies is developing the automated machines that will make gowns. Wuxly is contributing with its cut and sew production capabilities. Promation is helping Harbour Technologies build the machines that will enable Wuxly’s capacity expansion. Superior Technologies will also install these machines at a new production facility it is acquiring. More recently, a First Nations community from Michigan has shown interest in building a similar facility south of the border, and has gradually become a growing member of the team and will be the lead for the US market access. When these projects are completed, medical gown production can be scaled up to serve the entire North American market.

With the experience it gained through serving the highly-demanding automotive industry, Promation felt confident to pivot into the nuclear power generation market in the mid-2000s

As reflected by the company’s ventilator and medical gown initiatives, Promation excels not only at building collaborative relationships but also at transferring its expertise across different industries. That has allowed the company to diversify the markets it serves at strategic times.

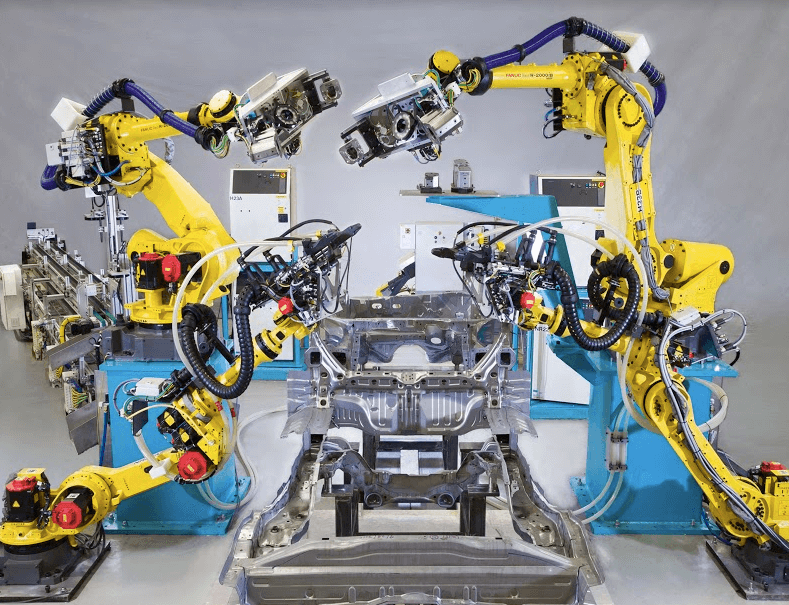

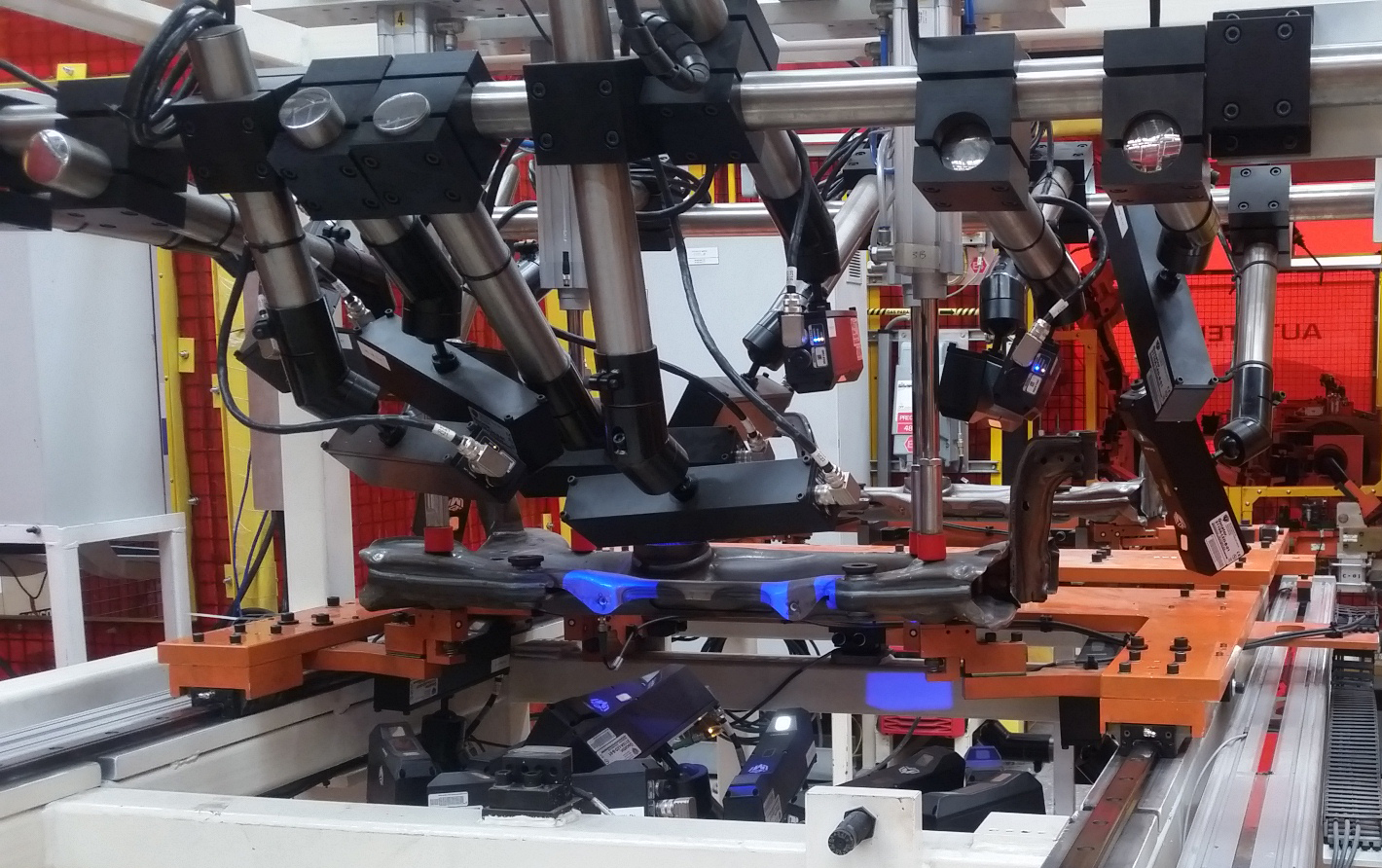

During its early years, Promation was primarily focused on supplying automated production systems to the automotive industry. By serving the automotive industry, the company built a strong foundation in quality assurance, creating reliable automation products for an industry focusing on high-technology, mass-scale production, and cost-efficiency.

With the experience it gained through serving the highly-demanding automotive industry, Promation felt confident to pivot into the nuclear power generation market in the mid-2000s. Major refurbishments projects were going live at the Canada Deuterium Uranium (CANDU) nuclear reactor sites in New Brunswick and Ontario. There was a short window of opportunity for new companies to enter into a supply chain that was long closed to new entrants. Promation quickly evolved itself to satisfy the stringent requirements of the nuclear power generation industry and earned its first contracts.

Promation has quickly become one of the leading developers of end-to-end automated systems used to irradiate, process, and handle medical isotopes, the most important ingredient of radiopharmaceuticals

Entering the nuclear market had three benefits for Promation. First, it created a lifeline for the company during the global financial crisis in 2007, as the automotive business was in decline. While competitors that relied solely on the automotive industry were starting to fail, Promation was growing, thanks to an expanding footprint in the nuclear power generation market. Second, it facilitated the company setting certain internal standards in order to meet the needs of an industry with very high quality assurance requirements. Finally, it facilitated Promation’s entrance into a fast-growing market related to nuclear power generation three years ago: radiopharmaceuticals—known more conventionally as Medical Isotopes.

Promation has quickly become one of the leading developers of end-to-end automated systems used to irradiate, process, and handle medical isotopes, the most important ingredient of radiopharmaceuticals. Without the expertise gained from serving automotive and nuclear power generation industries, this would not have been possible.

Entering new markets has not only fueled further growth but also earned Promation distinct competitive advantages

Today, Promation’s products help automate the entire medical isotope production process, from the irradiation of the raw material to its post-processing and packaging. Automating these steps allows medical isotopes to be developed more safely and shipped to the end user more quickly. As this market expands, the company expects that the need for its products will grow in parallel.

Entering new markets has not only fueled further growth but also earned Promation distinct competitive advantages. For example, through the ongoing work with developing and advancing the emergency ventilator (Pro-Vent), the company is learning how to navigate through Health Canada compliance and licensing processes for fully qualified medical device product innovations. That knowledge allows Promation to help its customers who are looking to bring new medical innovations to life by accelerating time-to-market and reducing product development costs.

While new growth opportunities have emerged recently, the nuclear and automotive businesses remain as Promation’s key sources of revenue growth. The fiscal year that ended in February 2020 was the company’s best sales year ever for nuclear, recording a 60 per cent growth year over year. The company now expects to see a 15-25 per cent growth year over year in its revenues from the automotive, automation, and nuclear businesses combined this fiscal year. Several trends are helping drive this growth.

In the nuclear power generation space, the growing importance of nuclear decommissioning and post asset life handling and processing are creating new opportunities for the company. In the automotive industry, in response to recent supply chain disruptions, reshoring initiatives are becoming more prominent. Automation and robotics contribute to the feasibility of those initiatives. In addition, automation systems are becoming more affordable and accessible for smaller manufacturers. Investments from Tier 2 and 3 automotive suppliers as well as emerging electric vehicle start-ups in North America are boosting the demand for Promation’s products.

Despite these positive developments, Promation also faces a challenge in the near future: the “Buy American” policies south of the border. To adhere to any regulations that may emerge, the company is actively exploring greenfield investments in the United States, or establishing strategic partnerships with local companies that it is not directly competing with to facilitate footprints south of the border to provide local support and bases of operation close to US customers.

While the business is growing, Promation is careful not to become complacent and fall behind technologically. To stay ahead of the competition, the company is leveraging collaborations in R&D too. For example, it is the key industrial partner with the University of Waterloo’s Multi-Scale Additive Manufacturing (MASM) Lab to develop next generation metal additive manufacturing technologies. Based on the Lab’s research, Promation has built an automated system that can print an object in any orientation using an 8-axis robot. This system can create unique geometries that cannot be achieved by using traditional 3-axis metal additive technologies.

Ontario’s automation and robotics industry plays a vital role in the expansion, scale up, and technological advancement of the manufacturing sector. Promation demonstrates that the industry can drive initiatives, collaborations, and innovations that have an even broader impact – whether they relate to reshoring activities, building a more independent domestic supply chain, facilitating Indigenous reconciliation, or supporting medical or metal additive manufacturing innovations.

For more information about Promation, visit https://www.promation.com/.

Published: November 2, 2021

BOS Innovations

BOS Innovations develops custom factory automation solutions to help companies reach greater levels of productivity and profitability. The company’s mission is to advance North American manufacturing through world class integration of automation systems with innovative engineering, build quality, and service.

CenterLine

CenterLine is a manufacturer of custom automated welding and assembly lines, as well as resistance welding-related products. The firm is known worldwide as a leader in fastener welding technology, which is used in the production of automotive components.

Innovative Automation

Located in Barrie, Ontario, Innovative Automation Inc. is one of the most creative manufacturers of custom automation solutions in North America. It is Innovative Automation’s Vision to “Be the first choice provider of automation solutions to global leaders in manufacturing”. To ensure that it is equipped to handle even the most complex machine solutions required by its customers, Innovative Automation has an electrical systems design team, a mechanical design team, a programming team, and a mechanical build team.

Bluewrist Robot & Vision Solutions

Bluewrist Robot & Vision Solutions designs and develops innovative industrial automation solutions in the fields of robot guidance and 3D machine vision.