-

Headquarters -

1150 Gardiners Rd, Kingston, ON, K7P 1R7

-

Year established -

2018

-

NAICS -

332710 - Machine shops

-

Major expansions -

-

Employees -

13

-

Exports -

-

Download -

Nuformex Precision Manufacturing

Innovation, customer service, and problem-solving have helped make Nuformex Precision Manufacturing the success story it is today

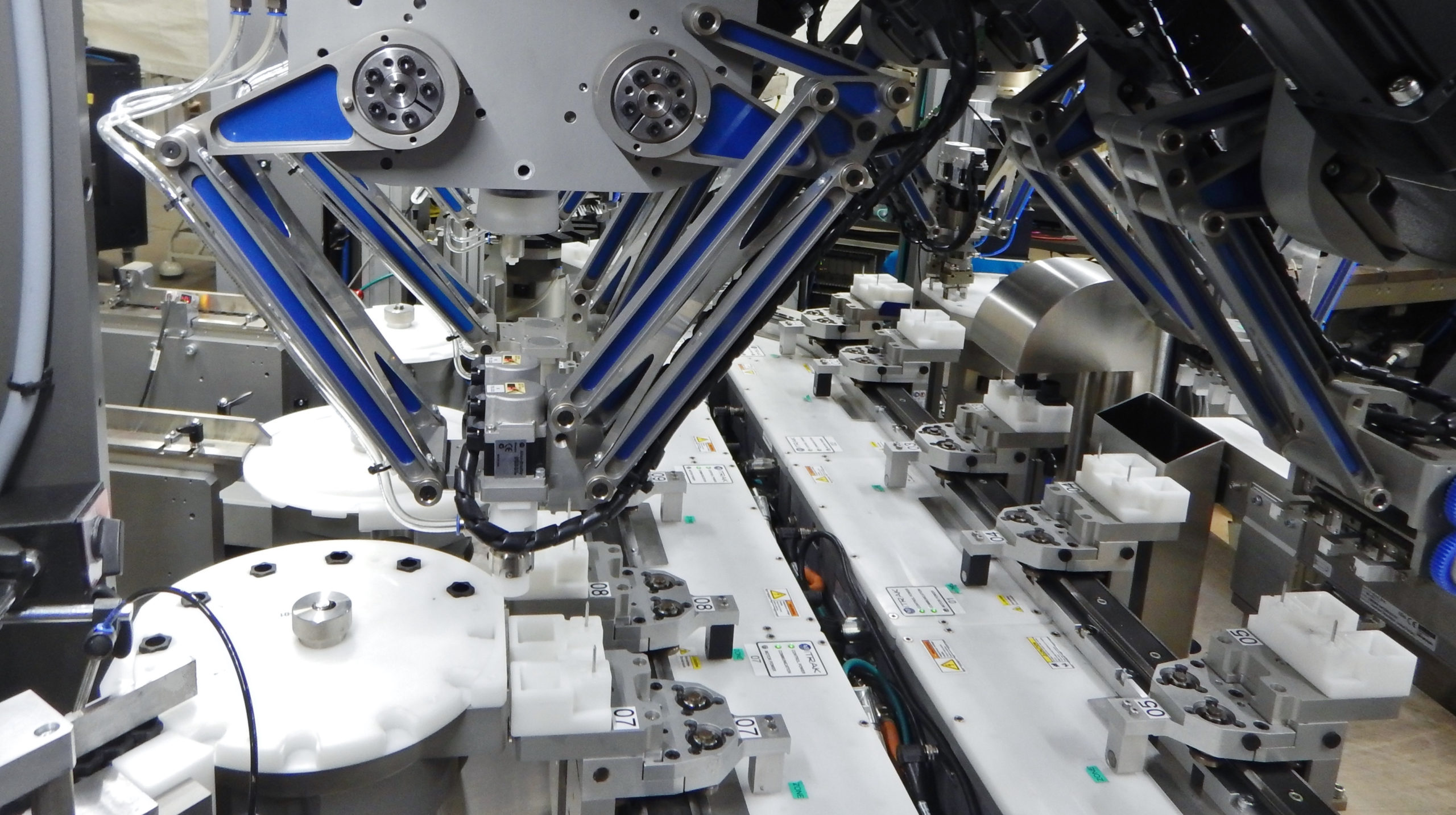

Lives were on the line when there was a national shortage of cartridges for COVID-19 testing last March. When a customer asked Nuformex Precision Manufacturing to supply parts for an automated assembly machine that would manufacture the cartridges, speed and quality were paramount.

Nuformex employees, the “back-end frontline workers,” as the company refers to them, rose to the challenge. Within eight weeks, they programmed, machined, and produced 174 different parts of various quantities for their customer. At the same time, they remained on budget and on schedule, and did not compromise on quality. When local supply chains mattered the most, Nuformex delivered.

Nuformex is a machine shop based in Kingston specializing in the precision machining of parts for automation equipment. The company emerged in 2019 with Paul Steele, Clay Crosby, and George Brunner leading the way. Previously, they led a team of machinists who formed the machining arm of Transformix Engineering, an automation equipment manufacturer based in Kingston. That team played an integral role in manufacturing the intricate parts used in Transformix’s products, specifically in its CNCAssembly® technology.

The company’s 13 employees combined have more than a century of experience in the machining business.

When Transformix’s intellectual property was acquired in 2018, Steele, Crosby, and Brunner saw an opportunity arise for the team of machinists. With support from Transformix’s former owner, they decided to spin off the machining arm and name it Nuformex. Their decision was driven by a passion to keep manufacturing in Canada and the opportunity to maintain their team members’ jobs in Kingston.

After the spin-off, the newly-independent Nuformex remained at its original facility in Kingston. It has since aspired to be more than an “average” machine shop. The company’s 13 employees combined have more than a century of experience in the machining business. The team also has a wealth of experience in prototyping, three-dimensional computer-aided design, and working with R&D teams and engineers. But the company really differentiates itself from its competitors with its reputation as a reliable and accessible production partner. And that reputation is a result of a tremendous amount of dedication. When most of the staff was away during the Christmas of 2019, for instance, Steele called on his family members to satisfy an urgent customer request. Thanks to the expertise of its employees and its positive reputation, the company has expanded its customer base rapidly. It now serves customers from a wide range of industries including automation equipment, solar energy, shipping, mining, and consumer goods.

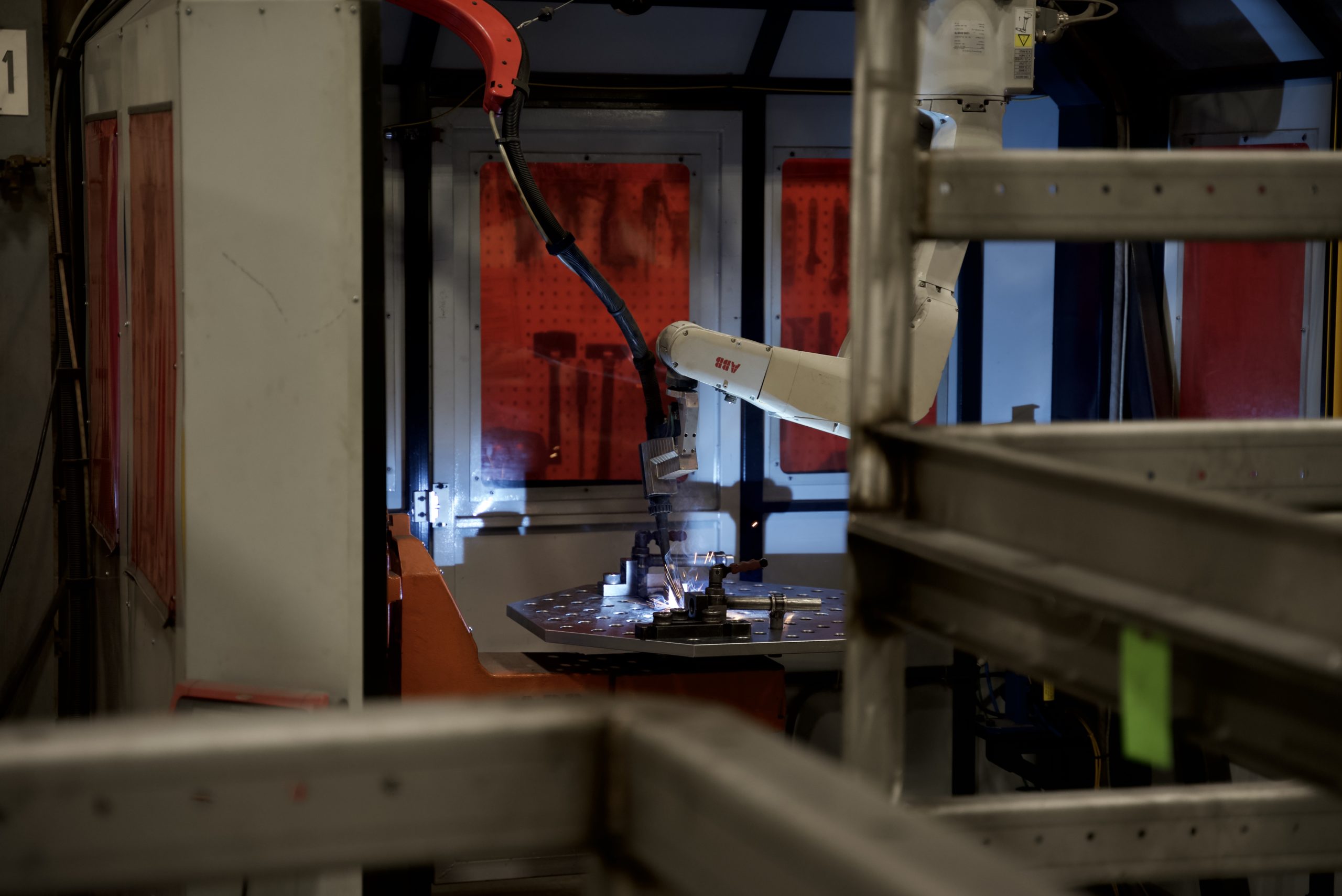

The company machines components from raw materials including aluminum, steel, stainless steel, titanium, copper, plastics, and exotic metals such as Nitronic 50 (a nitrogen-strengthened steel alloy). It sources these materials from local suppliers based between Toronto and Montréal. The typical production processes include turning, grinding, milling, and quality control. Complementary in-house capabilities include computer-controlled design, metal finishing, and prototyping. The company partners with local firms that offer additive manufacturing, surface treatment, and waterjet cutting services to satisfy customer needs. Having access to this local network of manufacturers is a key competitive advantage for Nuformex, allowing the company to provide a full suite of solutions that help its customers solve complex production challenges.

The pandemic brought on new challenges to executing this expansion plan but the company has responded in creative ways. For example, Nuformex’s marketing manager, Vanessa Pizzianto takes potential customers on virtual shop tours using an action camera. She notes that this innovation has earned the company new business during the COVID-19 pandemic.

Nuformex’s customers value the company’s ability to deliver results with little to no learning curve and also appreciate the accessibility of Nuformex’s leadership team. Customers can always reach Steele, Brunner, or Crosby when they need them. This helps Nuformex develop stronger relationships with its customers, which fosters innovation. For instance, a local seismic sensor manufacturer made frequent orders for a particular part that was expensive to produce in small volumes. In turn, Nuformex set up a bin stock program through which it produces parts that are needed repeatedly in higher-volume batches. It keeps an inventory for future orders. Customers can pull from that inventory when they need to and get the parts delivered to them within 24 hours. That is three to four weeks faster than the normal process. This solution helps start-up customers for whom early-stage cost effectiveness is critical. Established manufacturers also appreciate the quicker turnaround times that improve their speed to market.

Currently, the majority of Nuformex’s customers are based in Canada, but the company is keen to expand into the United States. The exchange rate provides a significant competitive advantage to Nuformex in the U.S. market. But Nuformex believes it can also develop strong relationships with companies south of the border by capitalizing on its core strengths. Steele notes that any company that values reliability, accessibility, and quality is a potential customer. The pandemic brought on new challenges to executing this expansion plan but the company has responded in creative ways. For example, Nuformex’s marketing manager, Vanessa Pizzianto takes potential customers on virtual shop tours using an action camera. She notes that this innovation has earned the company new business during the COVID-19 pandemic.

In order to support the company’s expansion into the U.S. market, Nuformex plans to apply to the CanExport SME program administered by the Government of Canada’s Trade Commissioner Service. This program offers up to $75,000 in funding to small and medium-sized companies to assist them with international market development activities. Nuformex believes that this support will be critical in executing its expansion plans. The company looks forward to having access to a dedicated professional advisor through this program as well.

Ideally, Nuformex would hire individuals with at least five years of experience in the trade. But due to the tight labour market, the company also hires less experienced individuals and trains them. It seeks candidates who demonstrate exceptional mechanical aptitude and a passion to learn the trade.

In addition, with support from the Kingston Economic Development Office, Nuformex will attend the Trade Accelerator Program (TAP) run by the Toronto Region Board of Trade. TAP is an initiative designed to accelerate the strategic development of businesses to expand into international markets. Separately, Nuformex is considering applying to the provincial Eastern Ontario Development Fund (EODF) for funding to invest in new production technologies. These investments would help the company grow and create more job opportunities.

Similar to other companies relying on skilled trades, Nuformex is challenged by the skills shortages in Canada and the extremely competitive labour market. Ideally, Nuformex would hire individuals with at least five years of experience in the trade. But due to the tight labour market, the company also hires less experienced individuals and trains them. It seeks candidates who demonstrate exceptional mechanical aptitude and a passion to learn the trade. To address the skills shortage, Nuformex partners have taught and have been involved with local colleges including St. Lawrence and Loyalist and high schools. Several apprentices from those schools were eventually hired by Nuformex.

Nuformex plans to expand its U.S. customer base and strategically use government funding opportunities to invest in new technologies to grow the business. In the meantime, the company is focused on doing what it does the best: helping its customers solve complex production challenges with its employees’ substantial experience.

With increased focus on local supply chains in the life sciences and medical device industries, Nuformex believes that there is an opportunity for local companies to tap into those markets. The company proved its capabilities at the beginning of the pandemic and now believes that it can serve those industries in the long term.

Published: May 6, 2021

Transformix Engineering

Transformix Engineering is exclusively focused on CNCAssembly® technology in the specialized niche of "continuous motion", and have developed it into a general solution for small-part assembly.

Chrima Metal Fabrication

Chrima Metal Fabrication is a leading custom and contract manufacturer of precision metal fabrications in Southwestern Ontario. With more than 50 years of experience in the industry, the firm creates high-quality custom products for a diverse range of industries.

Industrial Parts Manufacturing

Industrial Parts Manufacturing specializes in CNC machining, general machining, welding and fabricating.