-

Headquarters -

559 Douro Street, Stratford, Ontario, N5A 0E3

-

Year established -

1960

-

NAICS -

332999 - All other miscellaneous fabricated metal product manufacturing

-

Major expansions -

N/A

-

Employees -

80

-

Exports -

US, South America

-

Download -

Chrima Metal Fabrication

Chrima Metal Fabrication is a leading custom and contract manufacturer of precision metal fabrications in Southwestern Ontario. With more than 50 years of experience in the industry, the firm creates high-quality custom products for a diverse range of industries.

Located in Stratford, Ontario, Chrima Metal Fabrication (Chrima) is a manufacturer of custom metal fabrications. The firm has grown from a one-man operation on three acres of land in 1960 to a 65,000-square-foot manufacturing facility that is home to 80 employees today and is now embarking on Industry 4.0 implementation. With more than 50 years of experience in the industry, Chrima is a leading custom and contract manufacturer of metal fabrications in Southwestern Ontario. The company’s ability to create high-quality, custom products has attracted customers from a wide range of industries. Above all else, Chrima’s management is proud that the firm continues to operate in accordance with its objective of “empowering people and companies to build better futures.”

Chrima’s founder, Bill Christian, arrived in Canada in 1954 with the dream of running his own metal fabrication shop. He began working for a company in Stratford, where he built fire engines and other equipment. In 1960, Christian purchased three acres of land and used his time after work to dig a well there by hand, build a building, and purchase his own tools for designing and manufacturing metal structures. Over the following three years, Christian acquired customers and grew his business while continuing to work full-time for his original employer. By 1963, Christian’s business had grown to the point where he could leave his full-time job to focus on his company. Since then, Chrima has grown consistently, expanding its facility multiple times and acquiring new customers by constantly searching for opportunities in diverse industries. Throughout its entire existence Chrima has remained a family-run business. Bill’s son, Dan Christian, is now the CEO, and four of Bill’s grandchildren are employed at the firm.

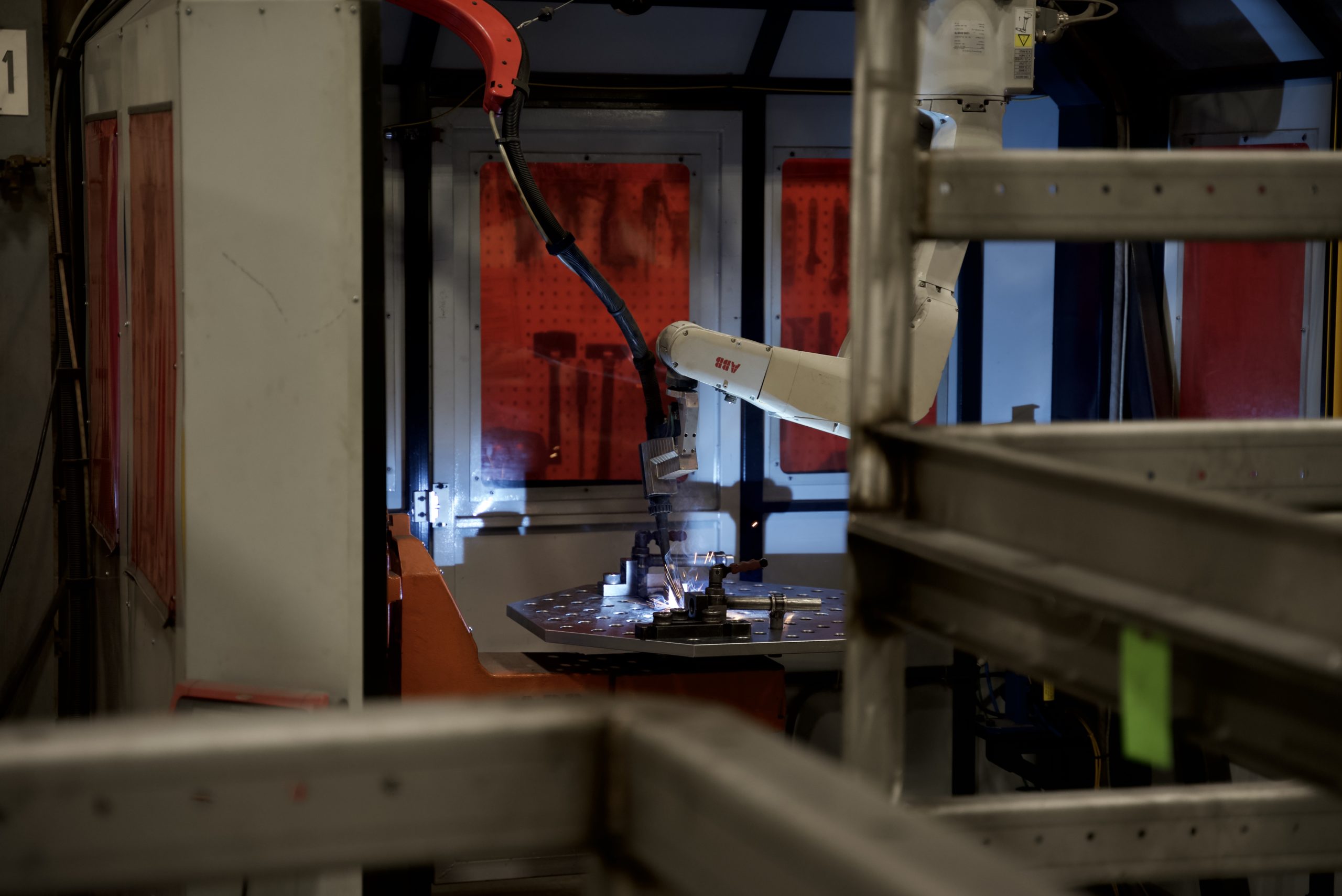

To ensure that it can manufacture any product requested by a customer, Chrima has strategically invested in a wide range of equipment. The company’s capabilities include flat laser cutting; tube laser cutting; press brake and rolling; tube bending; manual welding; robotic welding; engineering design; complex assembly; and delivery service. Chrima also recently invested in a 3-axis machine and a 5-axis CNC machine to further broaden its list of services. Despite the highly variable and fast paced nature of custom manufacturing, Chrima maintains a clean and safe workspace. For example, the welding department is equipped with central air vacuums and a filtration system to mitigate the fumes as they are created. Additionally, steel and carbon alloys are separated to ensure products remain uncontaminated and maintain high quality.

Chrima continues to vertically integrate by bringing select services in-house to reduce lead times for its customers.

After performing research on how to reduce lead times, the company found that firms often attempt to reduce physical production time by purchasing faster machines. However, a study on quick response manufacturing suggests that reducing the idle time of parts is a more effective method of reducing lead times. By vertically integrating, Chrima has more control over its supply chain, enabling the firm to effectively manage idle time on its work-in-progress and delivering more value to its customers. Moreover, Chrima has integrated extensive quality checks into its supply chain to ensure that customers receive only the highest-quality products. All supplier materials are examined, followed by additional quality checks throughout the manufacturing process and a final quality check of the end product, to confirm that all customer specifications have been accurately met.

The lasting relationships that Chrima has developed with its customers over the years have greatly contributed to the firm’s growth. Chrima’s management believes that there are certain characteristics that every firm should offer its customers, such as product quality, on-time delivery, exceptional customer service, and competitive pricing. In addition to exhibiting these characteristics, Chrima differentiates itself by presenting customers with new and innovative ideas, based on a constant desire to improve, and knowledge of recent industry trends. Customers value the company’s willingness to exceed expectations as frequently as possible, as well as its diverse capabilities. Chrima also has exceptional and long-lasting relationships with its machine suppliers and material handlers. For example, the firm purchased its first new machine from TRUMPF in 1972 (TRUMPF’s first sale in North America). Since then, Chrima has bought its sheet metal machines almost exclusively from TRUMPF.

Chrima had minimal exports during its early years of operation, focusing instead on manufacturing quality equipment for its customers across a range of industries within Ontario, such as forestry, construction, automation, mining, health sciences, architecture, as well as all-terrain vehicles for recreational or military use. In addition to manufacturing products that are tailored to meet unique customer requirements, Chrima has been researching the feasibility of developing a standard off-the-shelf product that could benefit its customers across multiple industries. In the late 1990s and early 2000s, Chrima’s exports grew to approximately 25 percent of its products. The majority of these exports were sent to the United States and South America (primarily Brazil). Remarkably, the firm has been able to enter a vast array of industries and expand its exports without engaging in traditional external marketing. Instead, Chrima frequently sends employees to networking events such as EMO Hannover and creates new customer relationships through personal interactions or word-of-mouth referrals.

When Christian started his company in 1960, he wanted to create an environment where employees were happy and enjoyed coming to work.

Many of Chrima’s current employees have been with the firm for more than 20 years, and some have been there since its inception, indicating that Christian was successful in creating his desired workplace environment. At present, Chrima employs approximately 35 office staff, of which eight are engineers, and runs two shifts on the manufacturing floor. When hiring, Chrima looks for individuals that will be a good fit with the company culture and have the right soft skills to succeed, because these individuals can be trained to take on any role within the company. To subsidize the cost of this training, Chrima utilizes funding from the Canada-Ontario Job Grant program. Currently, the firm is also exploring the possibility of developing co-op programs or rotational programs with both universities and colleges.

Chrima is a proud and active member of its local and provincial community. The firm donates parts to Skills Canada for its competitions, sponsors McGill’s electric race car competitions, and donates robotic parts to Conestoga College. In addition, Chrima offers apprenticeship opportunities to various local high schools, as well as to The University of Waterloo and Conestoga College. These opportunities help the company address the challenge of finding skilled employees, specifically in the welding department. The firm also recently hosted an Excellence in Manufacturing Consortium event at its facility.

As the firm continues to grow, Chrima plans to embrace the Industry 4.0 revolution by transitioning to a paperless facility. As part of its digital strategy, the company has added a manufacturing execution system to its enterprise resource planning software that allows for real-time data collection and data visualization. Chrima understands that Industry 4.0 is an ongoing development and there is currently no standalone solution, so it is prepared to research and adopt new technologies and processes when appropriate. Most importantly, Chrima will continue to ensure that all of its employees are involved in the firm’s decisions moving forward. Chrima’s management believes that in addition to being aware of the company’s future goals, all employees should have input into those goals and understand why they are being pursued. Keeping employees informed in this regard will help Chrima maintain its enjoyable workplace culture as it continues to expand.

Check out Chrima’s Instagram page here!

For more information about Chrima Metal Fabrication, visit their website.

Published: July 9, 2020

Advanced Design Solutions

Advanced Design Solutions Inc. is a designer and manufacturer of material-handling containers, racks, bins, and dunnage. The firm specializes in the production of steel shipping rack and assemblies that use structural steel components such as tubing, channels, angles, and flat bar.

Kropf Industrial

Kropf Industrial Inc. manufactures CONOLIFT marine hydraulic equipment, dock systems, and other equipment for the industrial and aquaculture sectors.

Abuma Manufacturing Limited

Abuma Manufacturing Ltd (Abuma) is a Build-to-Print metal fabricator capable of manufacturing custom components. Abuma fabricates the metal components and upper-level assemblies and integrates additional outside services like surface coatings, electrical, pneumatics, and purchased equipment as required.

Industrial Parts Manufacturing

Industrial Parts Manufacturing specializes in CNC machining, general machining, welding and fabricating.

Laval International

Located in Windsor, Ontario, Laval International (Laval) manufactures production-ready moulds and composite parts for a wide range of industries. In addition to manufacturing, Laval offers engineering and prototyping services to customers seeking turnkey solutions. International presence can be attributed to its commitment to providing customers with the most technologically advanced and effective products.