-

Headquarters -

245 McNaughton Rd E, Maple, ON L6A 4P5

-

Year established -

1981

-

NAICS -

335311 - Power, distribution and specialty transformers manufacturing

-

Major expansions -

2018, 2022

-

Employees -

100

-

Exports -

U.S.

-

Download -

Northern Transformer

Transformers are a key component of electrical infrastructure

Electrical power generated by traditional or renewable sources could not be easily delivered or put to practical use in homes or businesses without transformers.

Northern Transformer has been manufacturing these essential components for the safe transmission and distribution of power since 1981. While the basic technology of winding coils is tried and true, the transformer industry continues to evolve, and Northern Transformer is leading the pace.

Northern Transformer was founded in Vaughan in 1981 and found its niche in smaller and custom designed transformers. At that time, other multi-national transformer companies like General Electric, Ferranti Packard, Federal Pioneer, and Westinghouse were very prominent in Ontario and focused primarily on serving large scale, global customers. These multi-national companies eventually withdrew from Ontario to pursue global markets with factories located outside Canada.

The initial owner of Northern Transformer wanted to retire in 2012 and sought a buyer with the ambition and business acumen to lead the business forward. He found exactly that in Northern Transformer’s current owner, Giovanni Marcelli.

The new facility, which came online in 2016, was built to reflect Mr. Marcelli’s vision of growing the company by building larger and more sophisticated transformers

Mr. Marcelli had been enjoying his third week of retirement following the sale of his previous company, Accubid, which provided estimating and project management software for Electrical Contractors in Canada and USA. When the opportunity to rebuild Northern Transformer became available, Mr. Marcelli jumped at it with the clear intent of bringing transformer manufacturing prominence back to Ontario. His vision was to build a state-of-the-art manufacturing facility, grow the team with talented engineers and capable management, acquire the best equipment, tools, training, and software to ensure that the company was fully capable to serve the industry’s most demanding clients and requirements. Mr. Marcelli retained the original workforce in its entirety and opened a new 120,000 square foot facility about eight kilometres north of the original location.

The new facility, which came online in 2016, was built to reflect Mr. Marcelli’s vision of growing the company by building larger and more sophisticated transformers. Transformers are rated in megavolt amperes (MVA), which represents the electrical power that it can safely handle. This new facility built in 2016 allowed Northern Transformer to produce transformers up to 115 MVA.

Four years later, the planning of the next expansion and equipment investment commenced. The new 20,000 square foot expansion is now completed and will be in full production by April 2022. This expansion includes the implementation of the first-in-Ontario Vapour Phase Drying Technology – an elaborated drying process mandatory for high voltage transformers that uses vacuum chambers – and additional assembly workspace, storage, offices and a large meeting room to accommodate growing staff. Additional upgrades to the Test Bay and a dedicated enclosed area for the winding department (known as a Clean Room) were also implemented. These investments will increase Northern Transformer’s capability to produce up to 200 MVA at 230kV transformers which are widely used in power distribution and substations in Canada and USA. There are few suppliers that can manufacture such a range of transformers in North America and only Northern Transformer in Ontario.

We take care of our employees, our employees take care of our clients, our clients take care of our business

When Mr. Marcelli bought the company in 2012, there were 23 employees. Today, there are just over 100 employees with plans to reach 150 over the next two years. The production staff are very skilled workers proficient in transformer manufacturing. Mr. Marcelli came to Canada from Italy at the age of 20 and understands the challenges of being an immigrant. He takes pride in helping newcomers to Canada in finding opportunities for advancement in their work and community. The company commits considerable resources to the onboarding process in order to make sure that employees feel a sense of belonging within their first few weeks. Mr. Marcelli believes in the Circle of Success “We take care of our employees, our employees take care of our clients, our clients take care of our business.”

Northern Transformer designs each unit using advanced software to simulate, model, and validate each variable, while customizing each design to meet the client’s specifications and performance guarantees before the unit is built. With some units taking more than 6,000 man-hours to build, getting the design right is critical and 2 to 3 months of engineering is not unusual. Between 80 and 90 per cent of materials used to build the transformers are sourced through North American suppliers with a great majority in Ontario. Northern Transformer estimates that over 1,200 North American families are directly and indirectly supported through the supply chain and more specifically 900 Ontario families.

Two recent strategic partnerships have been proven instrumental to Northern Transformer’s growth plan. In 2018, Southern States, a 100 year old company and North America’s leading manufacturer of High Voltage Switching Equipment became a minority investor. Southern States is growing its mobile transformer business and needed a transformer manufacturing partner capable of supplying quality products suitable for the Mobile Substations. Mr. Marcelli recognized that he and Southern States’ owner, Raj Anand shared a similar story, suggesting that “good people associate with good people.” This investment has allowed the company to reach its goal of building units with capacity up to 200 MVA. Since the great majority of Southern States’ sales have been in the utility sector for over 100 years, the partnership also provides Northern Transformer access to U.S. and international markets.

Northern Transformer believes in the strategic importance of a North American domestic manufacturing capability for these critical assets in our electricity grid

The second partnership occurred in 2020 when Northern Transformer purchased the intellectual rights to VRT Power’s North American brand, products, and technology. VRT Power, located in Israel, supplied more than 500 transformers and mobile substations in North America. This represents a major opportunity for Northern Transformer to supply the equipment needed by these customers on an ongoing basis.

Northern Transformer believes in the strategic importance of a North American domestic manufacturing capability for these critical assets in our electricity grid. Its local presence ensures the supply and maximum responsiveness in the event of utility outages and urgent requirements. Where unfair trade practices (“dumping”) have occurred, Northern Transformer strongly supports the Canadian Border Services and Canadian International Trade Tribunal’s investigations to place appropriate tariffs to rectify these issues. At time of publication, the CBSA and CITT have investigated and imposed tariffs on importations from South Korea and Taiwan.

Northern Transformer’s head of R&D, Dr. Muhammad Ali Masood Cheema, Ph.D (UNSW), is a senior industrial and visiting research fellow at the Power Electronic Laboratory for Sustainable Energy Research at York University. The company participates in two of the Lab’s studies, both funded by National Sciences and Engineering Research Council (NSERC) grants. The studies are focused on power transmission using wind as the renewable source.

Whether it is with Southern States, VRT Power, or with its research partners, these alliances all have something in common – a fit with Mr. Marcelli’s vision of building a successful transformer manufacturing company in Canada that takes care of its people, their families, and the people involved in its supply chain. Canada has given him a place to fulfill his goal. Marcelli and his company are doing the same for others, building equipment that ensures the safe and reliable supply of electricity, critical to our future prosperity.

Published: February 15, 2022

Promation

Ontario’s automation and robotics industry plays a vital role in the expansion, scale up, and technological advancement of the manufacturing sector. Promation demonstrates that the industry can drive initiatives, collaborations, and innovations that have an even broader impact.

Sartrex Power Control Systems Inc.

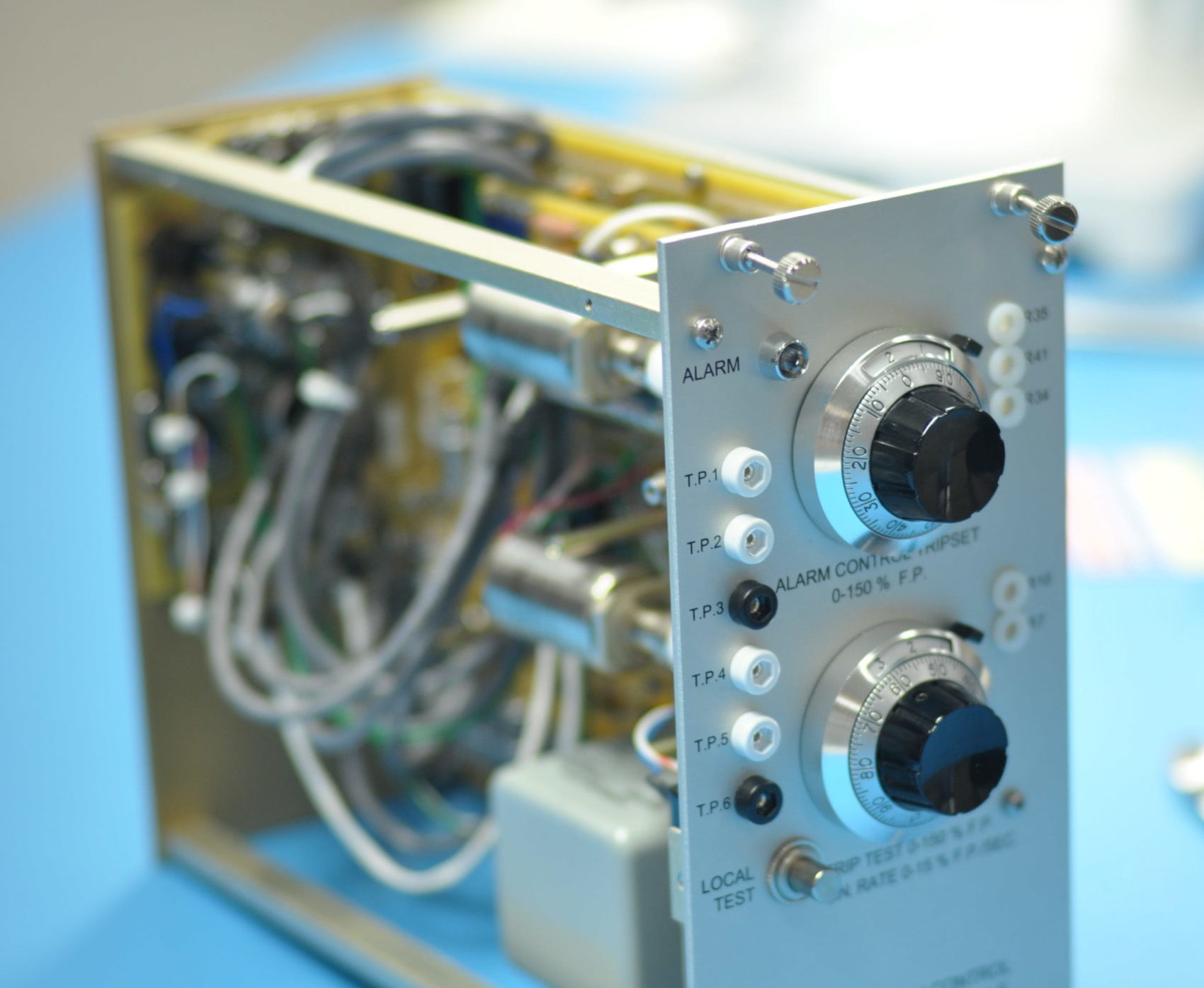

Sartrex Power Control Systems is a scientific instrumentation company that designs and manufactures custom safety critical equipment, primarily for the nuclear industry

Electronic Craftsmen

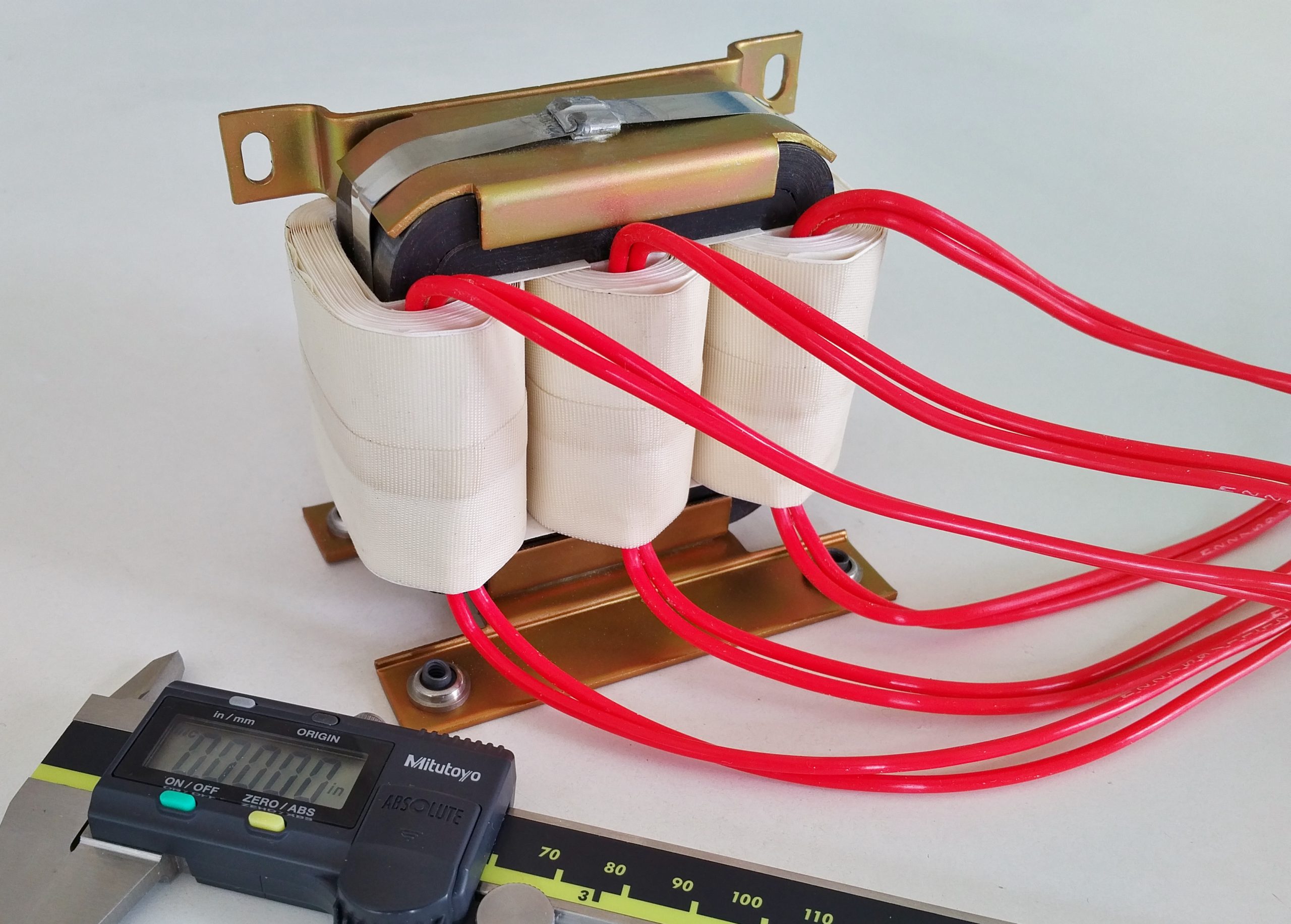

Electronic Craftsmen is a custom designer and manufacturer of specialty transformers, inductors, chokes, and reactors for use in power electronics applications.