-

Headquarters -

753 Ontario Street, Stratford, Ontario, N5A 3K1

-

Year established -

2010

-

NAICS -

326193 - Motor vehicle plastic parts manufacturing

-

Major expansions -

N/A

-

Employees -

170

-

Exports -

US, UK, Brazil, China, Mexico

-

Download -

MVA Stratford

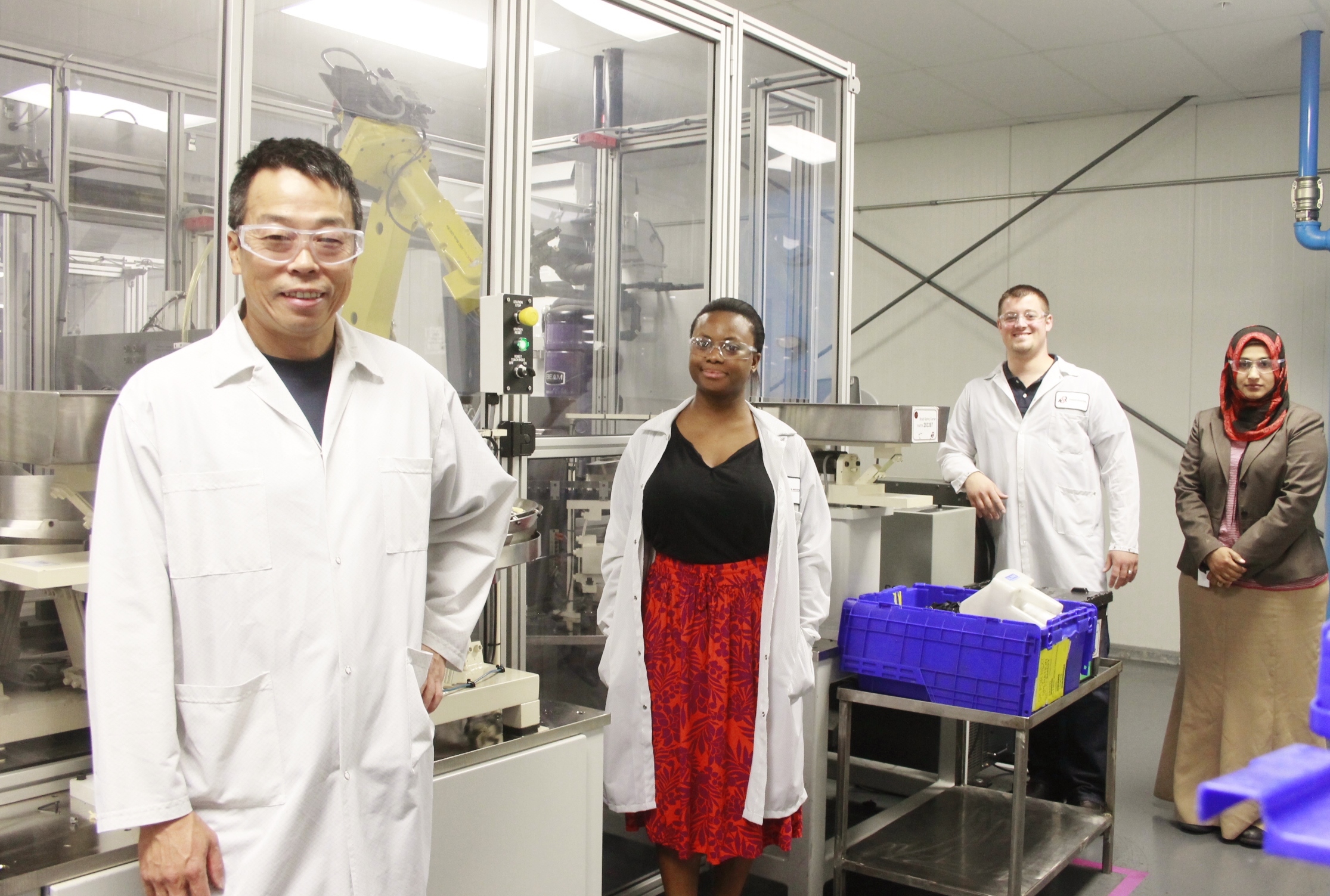

MVA Stratford Inc. is a manufacturer of custom plastic injection molded components. The firm has acquired customers from a diverse range of industries and developed strong, long-term relationships with its Tier 1 automotive customers.

MVA Stratford Inc. (MVA) is a manufacturer of custom plastic injection molded components, located in Stratford, Ontario. The firm operates out of a facility that began producing plastic molds in 1946. MVA’s constant communication with customers throughout the manufacturing process has helped it acquire customers from a diverse range of industries and develop strong, long-term relationships with its Tier 1 automotive customers. With more than 40 injection presses at its facility, MVA has the capacity to continue expanding its customer base and to maintain a rapid pace of growth.

The building in which MVA operates was originally owned by Samsonite for luggage assembly operations. Samsonite then purchased injection molding machines to manufacture smaller luggage. It wasn’t until the late 1980s that injection presses were utilized to manufacture plastic molds for the automotive industry. Samsonite developed a partnership with automotive parts manufacturer Schaeffler to transition the operation to a focus on automotive industry customers and implemented an improved quality management system to meet the industry’s stricter quality requirements. After another plastics firm bought the facility in 2003 and went bankrupt in 2010, MVA purchased all of the firm’s assets and immediately began strengthening relationships with Japan-based OEMs and Tier 1 suppliers in the automotive industry. Since this acquisition, MVA has grown its annual revenue from $2.3 million in 2010 to $27 million today.

The majority of MVA’s products are door seat components and intellectual property-protected components for both Honda and Toyota Tier 1 suppliers. However, the firm also manufactures products for other industries, including manufacturers of electronics, housewares, medical packaging, and cosmetics. MVA exports approximately 30 percent of its sales, primarily to the United States, Brazil, China, Mexico, and the United Kingdom. The firm’s management believes that its success with both domestic and foreign customers in various industries can be attributed to its dedicated customer service. MVA always strives to build a custom mold that will produce the best part, so it sources standard molds from a trusted supplier in Windsor and will only purchase standard molds that are built entirely in Canada. During production, MVA manufactures extra parts and is prepared to deliver those spare parts directly to its customers when this type of service is required in an emergency. The company also understands the importance of maintaining consistent and open communication with customers, providing them with information throughout the entire production process from engineering design to real-time data results.

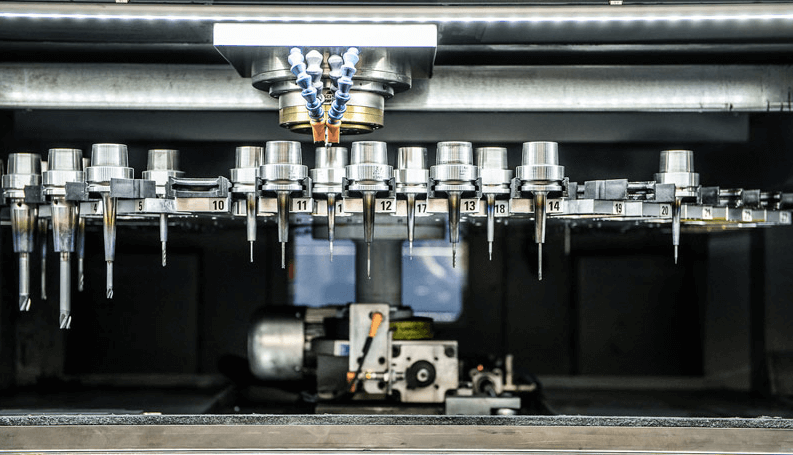

The main competitive advantage that differentiates MVA from its competitors is the firm’s integration of 24 high-speed robots into its production processes.

These robots enable MVA to run automated visual inspections for quality on its parts. This quality assurance is a major benefit for customers looking to manufacture complex parts. There have been instances where MVA has been responsible for the entire North American production of select parts because competitors are unable to manufacture the same parts without defects. The firm’s integration of robotic equipment has been so successful because prior to implementation, MVA ran trials with two different types of vision systems and then modified one of the systems to make it a perfect fit for MVA’s own production. MVA openly shares information with its customers who recognize the value that robotic systems can provide and request MVA’s advice or input regarding implementation of these systems to develop their own competitive edge.

To remain at the forefront of the industry and of changing technological trends, MVA has a management team that meets monthly to discuss new methods to improve its technology, facility, corporate structure, and manufacturing processes. This outlook enables the firm to provide customers with a better product or price point year after year. To assist with its research and development projects, MVA makes full use of the Scientific Research and Experimental Development (SRED) tax credit program. The firm recognizes the value that government funding can offer if properly used, especially since its American competitors do not have access to the same funding. MVA plans to focus its future research projects on preparing for new trends that could dramatically change the automotive industry, such as battery-powered vehicles. By looking into these trends, the firm hopes to develop an agile and flexible business model that ensures that it is prepared to capitalize on such trends when the opportunity arises.

From just 50 employees in 2010, MVA has now grown to include 170 employees. The firm has just under 100 employees working on the shop floor, running three eight-hour shifts of 33 individuals each. The remaining employees comprise 25 office staff and 50 support workers. The range of education varies greatly across employees, from certified electricians and millwrights on the shop floor to university graduates with engineering degrees in the office.

Finding young talent interested in trades or manufacturing is MVA’s only significant challenge, and this is largely due to the limited access afforded by its Stratford location. The company’s management has discovered that employees who excel at MVA are hard-working, passionate, and willing to learn; this has motivated MVA to hire individuals who do not necessarily have the appropriate industry-specific skills but fit with the company culture and are willing to learn. The firm then provides new employees with internal training and computer-based simulations to assist with their industry-specific development. To attract and retain employees, MVA is committed to maintaining a sense of fulfillment and happiness among them. For example, the company provides employees with small monthly gifts, gym memberships, work barbecues, and lunch for any staff that work over the weekend. The firm also offers flexible work hours to help employees create their own unique work-life balance.

Moving forward, MVA plans to stabilize its rapid pace of growth and look for more sponsorship and partnership opportunities. The firm values the importance of exercise and recognizes how sports can present children with benefits beyond athletics, so it sponsors local soccer, basketball, and baseball organizations. MVA also donates to its local United Way chapter and has begun searching for additional organizations that could benefit from its support. In terms of partnerships, MVA already has an apprenticeship program with Stratford Northwestern Secondary School. Its next step is to develop relationships with nearby universities and colleges, increasing its outreach to potential future employees. Content with the growth that MVA has recently experienced, the firm’s management will shift its focus over the next few years to establishing MVA within the local community before actively pursuing further growth.

For more information about MVA Stratford, visit their website.

Published: June 18, 2020

Canada Stampings

“Pressing on,” Canada Stampings provides custom metal stampings and assemblies using modern equipment and leading industry manufacturing techniques. Canada Stampings is a Tier II supplier of the automotive industry.

Autotube

Autotube Limited is an upper-tier supplier to the automotive industry that manufactures steel tubular automotive components and oil level indicators, offering a full range of services from designing and prototyping to tooling & production.

Armo-Tool

Armo Tool is a Tier 2 supplier and provider of “one-stop” precision tooling solutions, from small components to large machines that build Tier 1 parts. It has been family owned and operated since inception.

KSR International

KSR is a Tier 1 manufacturer of automotive parts, specializing in automotive sensors, electronic throttle controls, and adjustable and fixed pedals.

Cavalier Tool and Manufacturing

“Understand what needs to be done. Do it right the first time. Do it better tomorrow.” These are the words that have guided Tim Galbraith and Darcy Urquhart, Sales Managers at Cavalier Tool and Manufacturing (Cavalier) over the last three decades.