-

Headquarters -

300 High Street East, Strathroy, Ontario, N7G 4C5

-

Year established -

1975

-

NAICS -

336340 - Motor vehicle brake system manufacturing

-

Major expansions -

N/A

-

Employees -

180

-

Exports -

US, Mexico, Australia, Hungary, Thailand, South Korea, Brazil

-

Download -

Autotube

Autotube Limited is an upper-tier supplier to the automotive industry that manufactures steel tubular automotive components and oil level indicators, offering a full range of services from designing and prototyping to tooling & production.

Incorporating traditional practices and family-run business values into modern markets and technological advancements is no longer like mixing oil with water. Autotube is a Canadian manufacturing company that balances family practice and tradition with state-of-the-art technology to create a successful and thriving business.

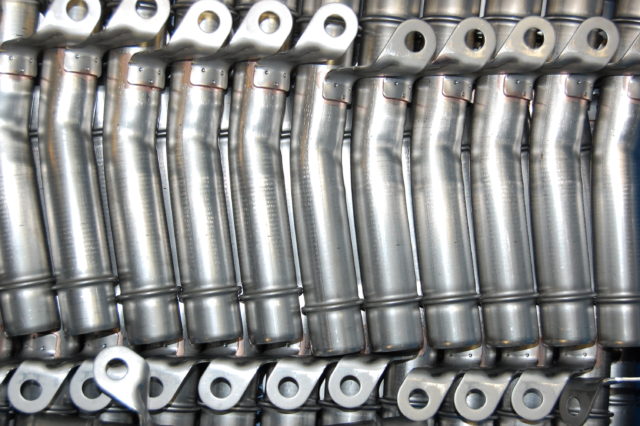

Autotube is a tier-one Canadian manufacturer of automotive supplies. Products range from oil and water tubes, to oil transmission indicator tubes and oil dipstick products. CEO and President of the Company, Peter Hall took over this family business from his father, the founder, after completing his engineering and MBA degrees at Western University. With forty years of experience in the industry and an employee base that stays current with technological advances and market changes, Autotube ships directly to Original Equipment Manufacturers (OEMs) all over the world. Ninety percent of sales are directed toward foreign manufacturers in the US, Mexico, South Korea and Brazil, to name a few. The remaining ten percent of sales are shipped to major Ontario auto manufacturers in Cambridge, Woodstock, Oakville and Oshawa.

The Hall family opened their first location in 1975 in Strathroy, Ontario, a center of Ontario’s auto production hub at the time. Autotube expanded it’s client base from Ontario to manufacturers south of the border in Michigan and later Kentucky. The small Canadian manufacturer used the old-fashioned method of face-to-face interaction to acquire their American clients during on-site visits. Keeping up with changes in the markets and the migration of engine manufacturing to foreign nations, the shift further south continued: Autotube expanded through North America and overseas to the other parts of the globe.

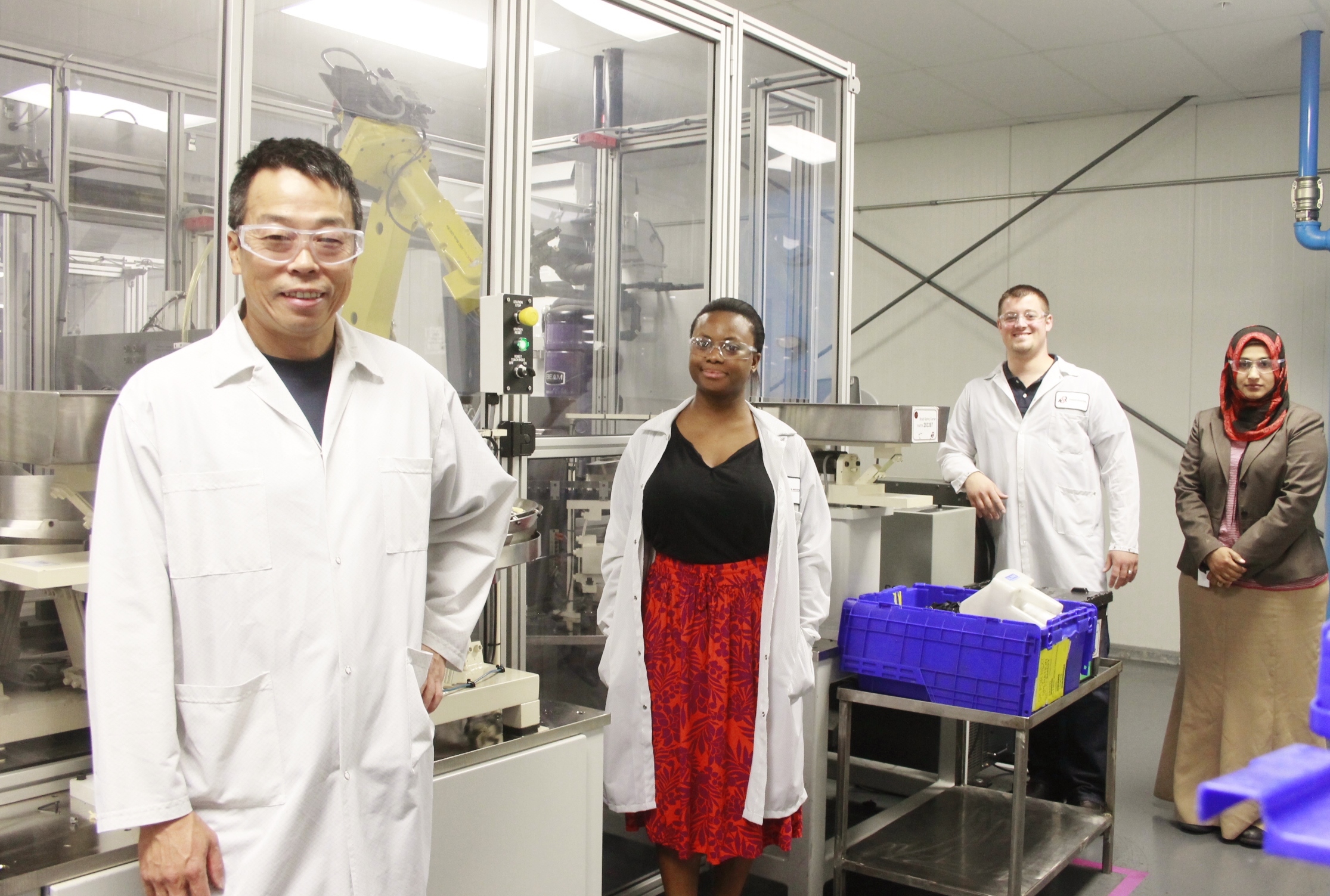

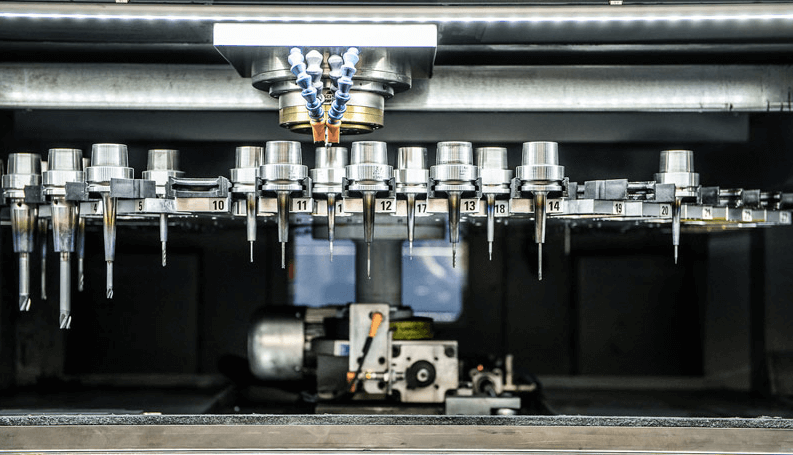

The trend continued on the supply side when a second manufacturing facility was built in Watford Ontario. Both facilities feature the latest technology and manufacturing techniques for car tubes and indicator products. These products are made with the aid of the company’s six welding robots and two “collaborative” robots. Collaborative robots are capable of completing mundane tasks that workers previously needed to perform, while stationed in an environment in which other employees can safely work around the robots with minimal guarding. Hall spoke of the company’s plans to purchase up to six more of the collaborative robots. These robots reduce costs and the need for employees to perform mundane and repetitive tasks.

Hall is certain the increase in automation will not affect the need of employment but rather reduce costs for the company, allowing them to maintain competitive prices and further expand the business. The shift for more automation is perfectly in-line with the shift in workers’ preferences: Today’s youth are looking for more cerebral work and less mundane work, and this is exactly the type of employees Autotube will need in the future. As manual labor plays an ever decreasing role in plants, the hiring of cheap labor abroad is non-advantageous. Rather local workers with computer programming skills and expertise in data entry and software will be sought to manage Autotube’s robots.

Today Autotube stands a major supplier in their niche market of automotive tube products. Hall is thankful for the success the company experienced following the recovery after the 2008 recession. The CEO predicts another bump in the road around 2021 when the economy will be due for a downturn. However Autotube expects to ride out these bumps. The company’s efforts to innovate and switch to a lean manufacturing culture will help to adapt to future changes. Hall underlines vital role of Autotube’s loyal and dedicated workforce, in the company’s success. Investing more and more to provide in-house metrics and data to the workers, Autotube is looking to improve process in as many areas as possible. Through implementing lean manufacturing concepts, team building activities and waste reduction techniques, the company is able to maintain a strong relationship with it’s employees.

Autotube has been successful using select government programs to supplement training and quality for employees. The company hopes to continue taking advantage of more of these programs and earn research and development credits to expand their product line. Autotube plans to dedicate increasing resources to R&D in the future through potential education partnerships and student internship programs. Their prototype shop is already in the midst of cooking up new, all plastic tubes, to be used in the light-weight cars of the future.

Showcasing the Hall family’s values of local business and employment while adapting to global markets and expanding in all fields of the business, Autotube has acquired harmony between tradition and modernization. With projected growth of five to ten percent in the next three years, and potential plans of further expansions in Ontario, Autotube is building the foundations to thrive in the years to come.

For more information about Autotube, visit their website.

Published: July 26, 2016

Autotube Limited is an upper-tier supplier to the automotive industry that manufactures steel tubular automotive components and oil level indicators, offering a full range of services from designing and prototyping to tooling & production.

KSR International

KSR is a Tier 1 manufacturer of automotive parts, specializing in automotive sensors, electronic throttle controls, and adjustable and fixed pedals.

Armo-Tool

Armo Tool is a Tier 2 supplier and provider of “one-stop” precision tooling solutions, from small components to large machines that build Tier 1 parts. It has been family owned and operated since inception.

Cavalier Tool and Manufacturing

“Understand what needs to be done. Do it right the first time. Do it better tomorrow.” These are the words that have guided Tim Galbraith and Darcy Urquhart, Sales Managers at Cavalier Tool and Manufacturing (Cavalier) over the last three decades.

Canada Stampings

“Pressing on,” Canada Stampings provides custom metal stampings and assemblies using modern equipment and leading industry manufacturing techniques. Canada Stampings is a Tier II supplier of the automotive industry.