-

Headquarters -

327 Sovereign Road, London, Ontario, N6M 1A6

-

Year established -

1993

-

NAICS -

333920 - Material handling equipment manufacturing

-

Major expansions -

2000

-

Employees -

35

-

Exports -

US, Mexico

-

Download -

Givens Engineering

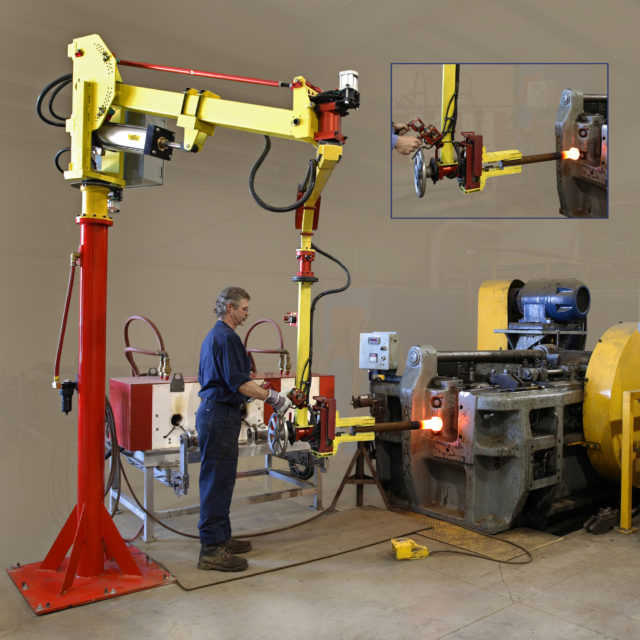

Givens Engineering Inc. designs and manufactures light cranes, manipulators and machinery for industrial use. The company specializes in lifting equipment and automated material-handling machines.

In 1992, Swiss-based automation and power technologies company ABB Ltd. shuttered its massive plant in London, Ontario. Nearly 500 employees were laid off. Ray Givens was one of them. A professional engineer with a master’s degree and more than six years’ industrial experience, Givens struggled to find a job. With no other prospects in sight, he took a leap of faith and incorporated his own business in 1993.

Today, Givens Engineering Inc. (Givens Engineering) is the industry leader for manipulators, light cranes and custom machinery devices. The company specializes in the design, development and manufacture of industrial lifting equipment and automated material-handling machines.

When Givens founded the company, industrial engineers were largely inexperienced with manipulators, and were most interested in custom lifting devices for cranes. Givens therefore started manufacturing and selling custom lifting devices. However, he held tight to his dream of developing his own manipulators.

In 1996, Givens hired his first employee and established his office at the Small Business Centre on Oxford Street in London, Ontario. The business expanded rapidly. Within five years, Givens Engineering became one of the largest firms in the Centre. The company required more space as orders for manipulators and custom lifting devices increased. Consequently, Givens decided to move to a bigger facility on nearby Firestone Boulevard. By 2005, Givens Engineering had become the number one manufacturer of manipulators in Canada.

With help from the Industrial Research Assistance Program (IRAP), the firm also started to develop its own cranes in 2007. With these light cranes, one can move loads quickly and easily, without the use of North-South-East-West motor drives. “My goal is to make the lightest cranes in the world,” says Givens. Today, Givens Engineering is a major supplier of light cranes across Canada.

The firm will break its own sales record in 2015, with75 percent of its sales coming from the automobile industry; Toyota, Honda, Ford, Cami Automotive, General Motors, Magna and Volvo have been some of Givens Engineering’s key customers. The company’s primary market is in Canada, with a smaller portion of sales coming from the U.S. market.

Givens welcomes the recent decline in the Canadian dollar because it helps the company attract more U.S. customers. With Givens Engineering’s high reputation and lowered prices, many new customers are now crossing the border to purchase the company’s products.

However, Givens realizes that the low Canadian dollar will only help the business in the short term. Meeting customers’ needs and the ability to quickly innovate are the keys to achieve long-term success. He explains, “We have the ability to improvise solutions to meet a variety of customers’ needs, and create custom parts and machinery in a very short time.”

Givens Engineering uses mass-produced standard components to its advantage. When a new project is received, the team can easily access existing and pre-tested inventory to create custom devices. “We are able to create a custom device within 10 days—that is one of our competitive advantages,” Givens says proudly.

Of the company’s 35 employees, 22 are shop floor workers, and most are from London with education or experience in specific trades including certified welders, skilled machinists, and controls specialists. “We are always trying to find the highest-skilled candidate in a specific trade,” notes Givens. When hiring an engineer, for example, “extreme mechanical aptitude” is what is being sought. “I am looking for someone who has the mental ability to visualize the machine, and to visualize the process,” explains Givens. In contrast, industrial experience is key when hiring, say, a machinist.

Givens Engineering has employed many graduates from Western University and Fanshawe College, and has experience hiring co-op students from those institutions as well. The company is looking to work more closely with regional educational institutions in the future.

When talking about government support, Givens is very positive and emphasizes the benefits that his company has gleaned from a variety of government funding programs. “We invest a significant portion of our annual sales into research and development, and the Scientific Research and Experimental Development Tax (SR&ED) program is the fuel that the company runs on,” he says. Givens Engineering has applied for SR&ED every year since 2000, and has achieved a 100 percent success rate with its past applications.

Looking to the future, Givens Engineering aims to maintain its status as the largest manipulator manufacturer in Canada, and soon, become the largest manufacturer of light cranes. Foreign markets are beckoning, and Givens Engineering is ready to take the leap to compete.

For more information about Givens Engineering, visit their website.

Published: July 22, 2016

Timberland Equipment

Timberland Equipment is a global leader in the integrated design, manufacture and support of engineered winches, hoists, sheaves, derricks and tensioning equipment for the world’s most challenging infrastructure and capital equipment projects.

Transformix Engineering

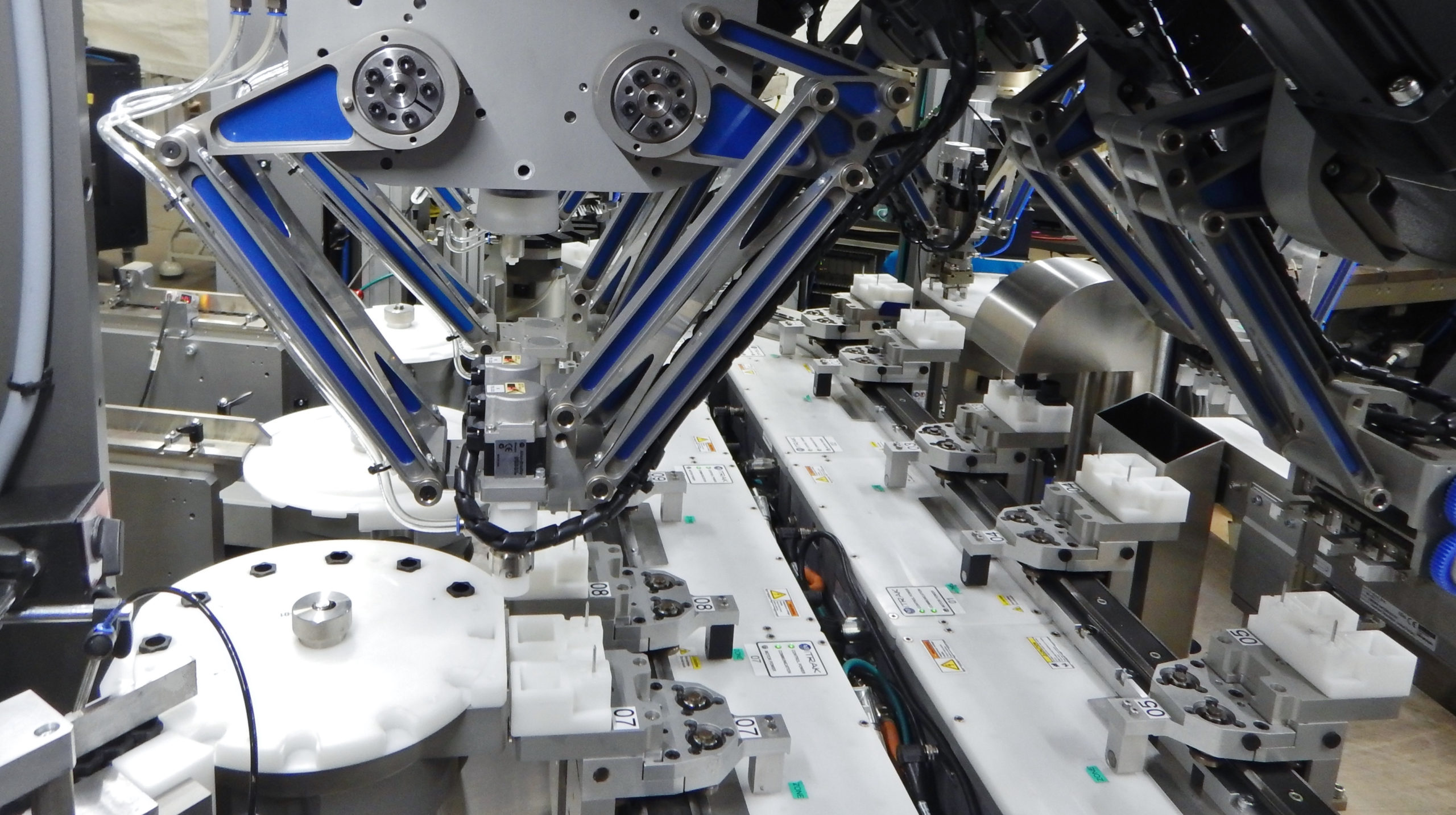

Transformix Engineering is exclusively focused on CNCAssembly® technology in the specialized niche of "continuous motion", and have developed it into a general solution for small-part assembly.

CenterLine

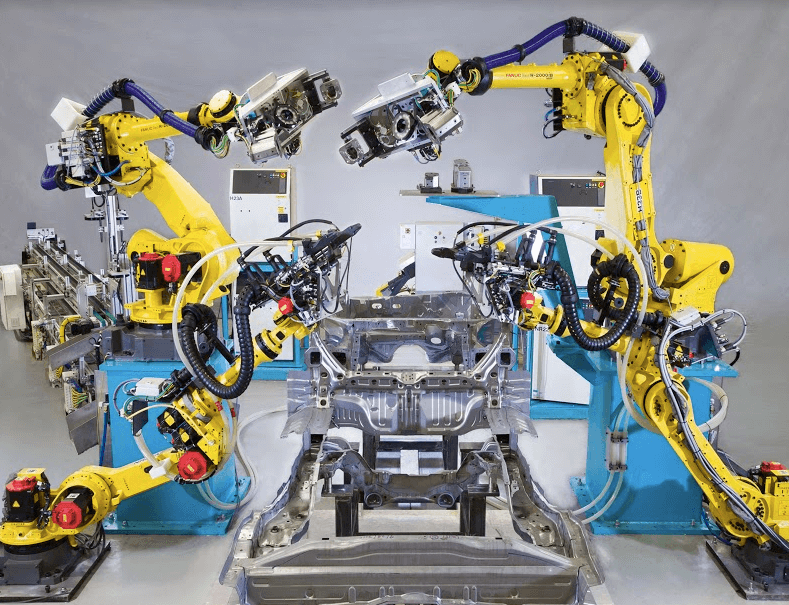

CenterLine is a manufacturer of custom automated welding and assembly lines, as well as resistance welding-related products. The firm is known worldwide as a leader in fastener welding technology, which is used in the production of automotive components.

Innovative Automation

Located in Barrie, Ontario, Innovative Automation Inc. is one of the most creative manufacturers of custom automation solutions in North America. It is Innovative Automation’s Vision to “Be the first choice provider of automation solutions to global leaders in manufacturing”. To ensure that it is equipped to handle even the most complex machine solutions required by its customers, Innovative Automation has an electrical systems design team, a mechanical design team, a programming team, and a mechanical build team.

Linear Transfer Automation

Based in Barrie, Ontario, Linear Transfer Automation is a global supplier of press transfer automation, blank feed systems, and press-to-press automation. Linear is able to customize its automation solutions to fit specific equipment geometry and requirements for customers.