-

Headquarters -

500 Hudson Dr., Dorchester, Ontario, N0L 1G5

-

Year established -

1996

-

NAICS -

333248 - All other industrial machinery manufacturing

-

Major expansions -

2013, 2017

-

Employees -

99

-

Exports -

US, Mexico, China

-

Download -

BOS Innovations

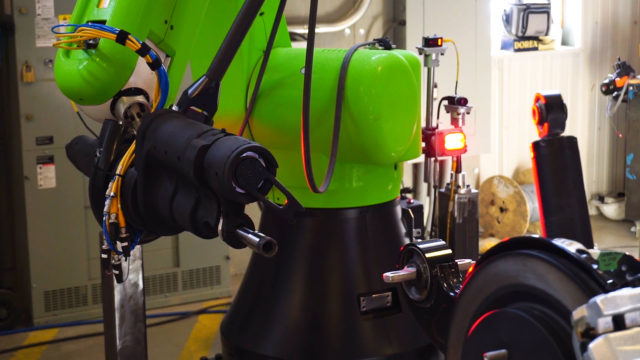

BOS Innovations develops custom factory automation solutions to help companies reach greater levels of productivity and profitability. The company’s mission is to advance North American manufacturing through world class integration of automation systems with innovative engineering, build quality, and service.

BOS Innovations Inc., located in Dorchester, Ontario, designs and manufactures custom factory automation solutions. BOS strives to help advance North American manufacturing through high-quality integration of automation systems. The company prides itself on conducting business with the highest level of honesty, respect, and dedication toward its customers, employees, and suppliers. For more than 20 years, BOS has helped companies improve productivity and profitability through its provision of innovative automation solutions.

In 1996, Casey Huigenbos founded BOS Innovations with the intent of manufacturing assembly systems for the automotive industry. However, in the early 2000s, the automotive industry began to drastically change as robotics became an integral component of the industry. BOS embraced this industry trend and began slowly incorporating robotics into its products. At the beginning of the economic downturn in 2008, Casey’s son, Ben, became the President of the company. With fewer than 20 employees at the time, Ben realized he had to prioritize the development of new products that incorporated robotics in innovative ways to remain competitive in the automotive industry. This need to innovate remains a core part of BOS’ strategy and has led to the addition of welding and laser capabilities as core competencies. More recently, BOS has become an industry leader in the integration of collaborative robots and developed expertise in vision inspection applications. In 2013, BOS moved into a larger facility to accommodate the increased demand for its products, as well as its larger workforce. Growth has been rapid and constant, which has necessitated two expansions of this facility since 2016.

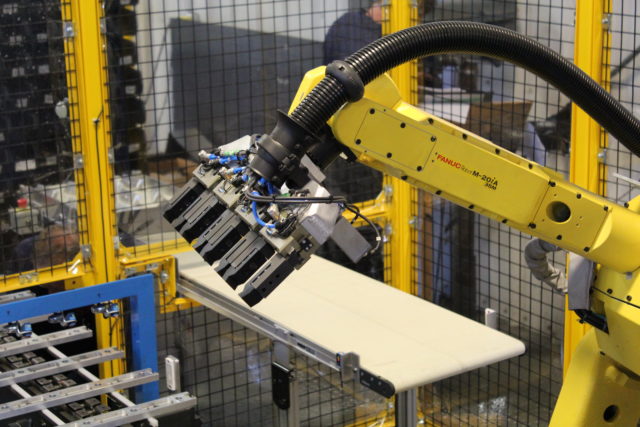

Although the majority of the company’s customers are Tier 1 suppliers, Tier 2 suppliers, and OEMs in the automotive industry, the technology deployed by BOS can be easily adapted to benefit firms in other industries. Robotics are typically used to increase productivity for firms that manufacture high volume products. However, the robotic technology designed by BOS is also capable of improving productivity for firms that manufacture a larger mix of products with lower volumes. The company’s dedication to diversifying its capabilities is the reason it was able to successfully expand into the aerospace, consumer, resource oil & gas, and medical industries.

The commitment to product quality and on-time delivery demonstrated by BOS over the past 20 years has resulted in the majority of its sales coming from repeat customers who have placed their unwavering trust in the company’s capabilities and service. Customers across all industries value the ability of BOS to manage an entire project from start to finish, which is possible because of the diverse skillset of the company’s employees. The wide range of employee skills at the company also allows BOS to successfully manufacture innovative solutions for unique customer needs, which is another reason why customers are confident in approaching BOS with new and challenging projects. Since 2012, the company has experienced a sales growth of 400%.

Employees at BOS range from mechanical, controls, software, and systems engineers, to skilled trade workers with certification in tooling, fabrication, wiring, and plumbing, to a sales and applications team. Having a diverse team allows the company to design, build, and integrate a complete project internally. The difficulty and range of successful projects completed by BOS has resulted in the company developing a reputation as an innovative and successful company. This reputation helps the company attract new employees as it grows because talented and innovative workers often have the desire to work with other skilled colleagues.

Controls and programming engineers, as well as skilled trade workers, are the most difficult positions to fill. BOS addresses this challenge by providing university and college students with co-op and internship opportunities. This allows BOS to train students and develop the skills they must have to be well-prepared employees. Students who are eager to learn or perform well during their tenure at BOS are given the opportunity to work full-time for the company after completing their education. Universities and colleges from which BOS typically recruits are Western, Waterloo, Conestoga, and Fanshawe. Students are treated as if they are newly hired workers, meaning they are immersed in the business immediately and given important tasks to complete on customer projects or R&D initiatives. BOS believes the best marketing tool is providing their student employees with a developmental experience, so they will return to their educational institutions and discuss how beneficial their time at BOS Innovations was to them.

BOS Innovations understands the importance of using its success to give back to the local community through various initiatives. The company frequently donates to charitable organizations such as the Make a Wish Foundation and the Salvation Army, even though these types of foundations are not related to manufacturing or robotics. Employees at the company are given the opportunity to offer input on which charities they would like to be involved with.

As a successful manufacturing company, BOS also believes it must help motivate high school students to continue studying STEM subjects (science, technology, engineering, and mathematics). The company has provided support for the study of STEM subjects through its sponsorship of FIRST Robotics for multiple years and has agreed to be the title sponsor of FIRST Western for the second consecutive year. Ben Huigenbos believes the growth of FIRST Robotics will help preserve one of the benefits of being a manufacturing firm located in Ontario, which is the talented pool of workers available due to the rich manufacturing history and culture of the province.

BOS has effectively utilized select government funding programs to assist with the development of internal talent. Additionally, both the Automotive Supplier Competitiveness Improvement Program and the Scientific Research and Experiment Development Tax Incentive have been utilized to fund various R&D initiatives. BOS is aware that investment in R&D must continue to stay at the forefront of the industry. Co-op students play an important role in supporting the work performed on R&D projects with the help and mentorship of an R&D manager. The manager utilizes a systematic approach to determine which projects are worth pursuing further. Projects that are worth pursuing relate to the company’s core business values, address industry trends and customer needs, and are within the current capacity and capability of the company.

The economic crisis of 2008, paired with the sudden change in leadership to Ben upon Casey’s passing, is the greatest challenge to date that BOS Innovations has overcome. Ben was able to lead the business through the crisis in 2008 by paying attention to industry trends, and he was willing to embrace the changes BOS needed to undergo to remain competitive. Although adopting advanced technology and manufacturing robotics was a risk at the time, BOS survived the 2008 downturn because it was able to secure enough business from loyal customers who trusted the company even when things seemed bleak. The initial step to adopt simple robotics in response to trends observed in 2008 allowed BOS to easily add laser and welding capabilities a few years later, which greatly contributed to its rapid growth and current trajectory as a company.

A major challenge that BOS faces in the near future is dealing with the political instability currently within the United States. Approximately 25-30% of sales are made up of exports, but this percentage will decrease if the uncertainty surrounding trade in the U.S. continues. However, if the trade uncertainty is stabilized, BOS is looking to improve its global presence by increasing exports. The company is also developing plans to secure customers in Western Canada so that sales can be increased through a different avenue, which will help mitigate the negative impact on exports that may result from continued trade uncertainty.

Short-term goals for BOS involve stabilizing changes in leadership, employees, and processes that have occurred in response to the recent and rapid growth experienced by the company. This rapid growth within a short time-period required BOS to analyze its new size and capabilities and prioritize establishing a stable working environment in the short-term to better prepare the company for future growth and new technology adoption.

An important long-term goal is the continued expansion into new markets and industries, both domestically and globally. BOS can put itself in a position to experience sustainable growth by diversifying into various growing automation markets, rather than relying on repeat customers from existing automation markets. The recent trend being referred to as Industry 4.0 presents BOS with an expansion opportunity because new potential customers are demanding this advanced technology, providing BOS with a concrete idea of the products potential customers desire.

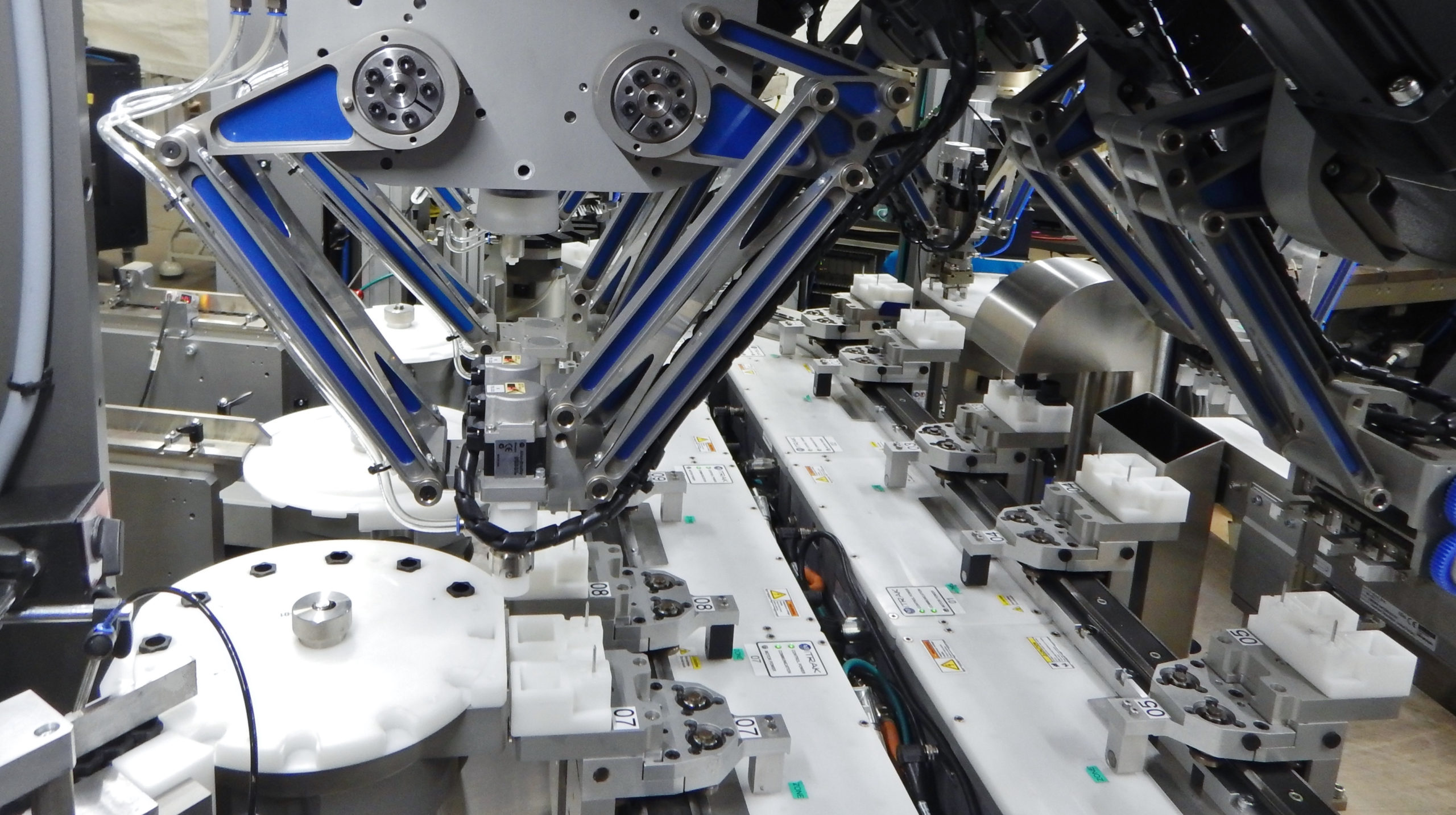

Another significant goal BOS plans to achieve over the long-term is the implementation of current R&D initiatives into customer products. One major R&D project that BOS believes will provide great benefit to its customers is the use of artificial intelligence on the production line in real time, to perform better and faster quality control inspections. BOS is also working on incorporating big data analytics into its machines so that customers can perform preventative maintenance. BOS will continue to offer new technology to its customers to ensure customers remain confident in the company’s ability to identify and realize the best possible automation solutions.

For more information about BOS Innovations, visit their website.

Published: July 31, 2018

Transformix Engineering

Transformix Engineering is exclusively focused on CNCAssembly® technology in the specialized niche of "continuous motion", and have developed it into a general solution for small-part assembly.

Angstrom Engineering

Angstrom Engineering Inc. is a leading manufacturer of thin film vacuum deposition equipment and vacuum chambers equipment. The firm specializes in designing, manufacturing, selling and servicing machines that deposit thin films, (growing layers of materials on a substrate with thicknesses that can range from less than one nanometer to several microns).

Linear Transfer Automation

Based in Barrie, Ontario, Linear Transfer Automation is a global supplier of press transfer automation, blank feed systems, and press-to-press automation. Linear is able to customize its automation solutions to fit specific equipment geometry and requirements for customers.

Givens Engineering

Givens Engineering Inc. designs and manufactures light cranes, manipulators and machinery for industrial use. The company specializes in lifting equipment and automated material-handling machines.

Abuma Manufacturing Limited

Abuma Manufacturing Ltd (Abuma) is a Build-to-Print metal fabricator capable of manufacturing custom components. Abuma fabricates the metal components and upper-level assemblies and integrates additional outside services like surface coatings, electrical, pneumatics, and purchased equipment as required.