-

Headquarters -

95 Erie Street South, Ridgetown, ON N0P 2C0

-

Year established -

1946

-

NAICS -

336390 - Other motor vehicle parts manufacturing

-

Major expansions -

2014

-

Employees -

450

-

Exports -

US, Mexico, EU, Asia-Pacific, Central America

-

Download -

KSR International

KSR is a Tier 1 manufacturer of automotive parts, specializing in automotive sensors, electronic throttle controls, and adjustable and fixed pedals.

In the 1940s, in a tiny garage in Ridgetown, Ontario, an auto parts maker was born. Today, this manufacturer has become a leading Tier One supplier and global exporter of sophisticated auto parts, with sales exceeding $300 million. The firm is KSR International.

KSR traces its roots to a small manufacturer of tractor hitches established in the 1940s. Two decades later, the firm, then called Kaiser, was acquired by a Michigan company and management shifted the core business to component manufacturing for heavy trucks. The company was soon restructured, renamed KSR, and guided towards the gas pedal assembly industry. Today, KSR still retains its heritage of industry leadership in pedal design and manufacturing, while making successful inroads in electronic sensors.

As a Tier One manufacturer, KSR directly supplies auto assemblers. The Big Three in North America are key customers: GM, Chrysler, and Ford, with Ford by far the largest. Other household names supplied by KSR include Volkswagen, Hyundai, Land Rover, Nissan, Volvo, and Jaguar.

With seven manufacturing facilities and several supporting offices worldwide, KSR maintains a strong global presence. R&D offices are located in Germany and Canada, with a sales office in Michigan and manufacturing in North America, Asia, Europe and Latin America. KSR is also exploring strategic alliances in India and Australia.

Sustaining success requires constant vigilance. Vice President of Manufacturing Steve Ross explains that KSR continually tunes its strategy to align with the latest direction in the business environment. Seeing that the market for basic sensors was highly saturated, for example, they diversified into high-tech units.

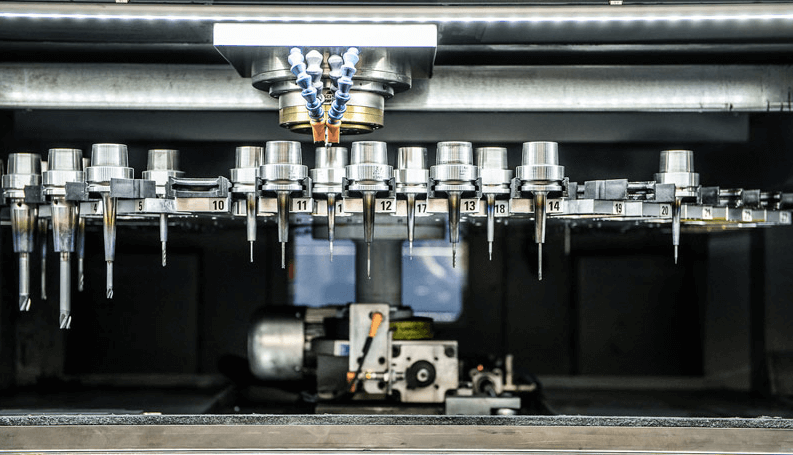

Climbing upward on the intellectual property ladder has become KSR’s modus operandi. This entails making more sophisticated products that KSR can patent. Since the early 2000s, the focus has been on electronics as the means to sophistication. In fact, their main product, the electronic throttle control (ETC) pedal, has for years defined the industry standard.

To further enhance their competence in electronics, KSR acquired the U.K. company Electronic Motion Systems in 2014. “It’s obvious that our future lies in shrinking our units,” Ross says. In the fast-paced technological world, staying ahead means making a product that’s as good as or better than your competitors, but smaller.

No matter how impressive it is, however, simply handing a standard finished product to a customer no longer suffices. Unlike their competitors, Ross says, KSR is reactive to its customers’ needs. Although they do stock standard products, most are custom engineered to their customers’ specifications.

While some variant of “putting customers first” now permeates almost every company’s mission statement, KSR really walks the talk. This is obvious in their tradition of custom manufacturing. It’s also the key reason for continuing to headquarter in Ridgetown, Ontario instead of relocating to China. They understood that their current customers value physical proximity. If honouring that commitment meant foregoing China’s low labour costs, then it was a price worth paying.

When asked about the one thing that would help KSR attain even greater success, Ross instantly replies: people. Their pivot to electronics in recent years only required a slight skill upgrade for the majority of their workers, who work on the shop floor. The main challenge, Ross admits, is attracting highly skilled workers with university degrees. As the company grows, engineers –particularly electronics engineers – are essential.

For now, there seems to be a solution. Every cloud has a silver lining, and even Research In Motion die-hards might appreciate that the giant’s retrenchment has allowed for an outflow of human capital to talent-hungry SMEs. For KSR, the concentration of footloose electronics engineers came at an opportune time, and the company raced to open a new R&D facility in Kitchener to attract this treasure trove of talent.

To meet the company’s ever increasing demand, KSR is also adopting more proactive hiring practices. This means venturing farther afield for job fairs and campus recruiting events. For example, KSR’s Engineering Manager recently attended a job fair in Windsor for the first time.

They are also exploring partnerships with educational institutions. For KSR, these partnerships serve the dual function of attracting bright university students and achieving synergies in R&D. Ross reports that KSR is currently developing a system for low-pressure natural gas containment in collaboration with a technical university. This is the kind of partnership that will ensure KSR’s growth for years to come.

By leveraging regional talent, putting customers first and pivoting to advanced technologies, KSR is well positioned to continue its climb up the ladder of manufacturing success.

For more information about KSR International, visit their website.

Published: August 9, 2016

KSR is a Tier 1 manufacturer of automotive parts, specializing in automotive sensors, electronic throttle controls, and adjustable and fixed pedals.

Armo-Tool

Armo Tool is a Tier 2 supplier and provider of “one-stop” precision tooling solutions, from small components to large machines that build Tier 1 parts. It has been family owned and operated since inception.

Cavalier Tool and Manufacturing

“Understand what needs to be done. Do it right the first time. Do it better tomorrow.” These are the words that have guided Tim Galbraith and Darcy Urquhart, Sales Managers at Cavalier Tool and Manufacturing (Cavalier) over the last three decades.

Canada Stampings

“Pressing on,” Canada Stampings provides custom metal stampings and assemblies using modern equipment and leading industry manufacturing techniques. Canada Stampings is a Tier II supplier of the automotive industry.

Autotube

Autotube Limited is an upper-tier supplier to the automotive industry that manufactures steel tubular automotive components and oil level indicators, offering a full range of services from designing and prototyping to tooling & production.