-

Headquarters -

91 Trillium Dr., Kitchener, Ontario, N2E 1W8

-

Year established -

1992

-

NAICS -

333248 - All other industrial machinery manufacturing

-

Major expansions -

2009

-

Employees -

35

-

Exports -

US, Russia, China, India

-

Download -

Angstrom Engineering

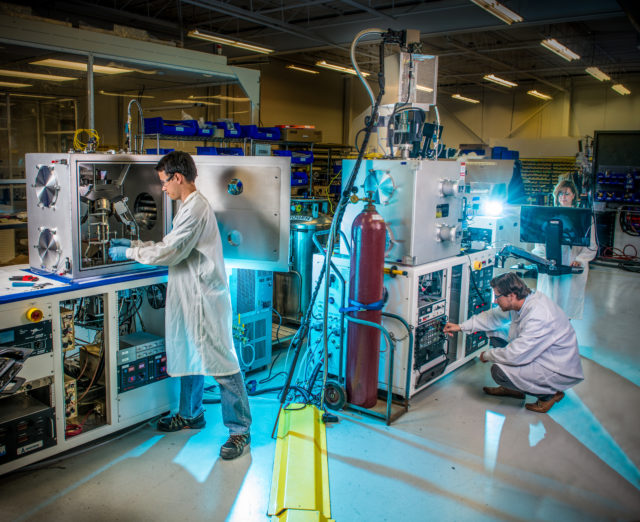

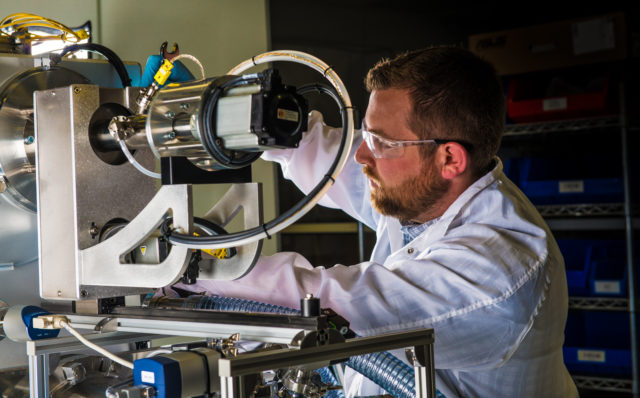

Angstrom Engineering Inc. is a leading manufacturer of thin film vacuum deposition equipment and vacuum chambers equipment. The firm specializes in designing, manufacturing, selling and servicing machines that deposit thin films, (growing layers of materials on a substrate with thicknesses that can range from less than one nanometer to several microns).

Angstrom Engineering Inc. (Angstrom), based in Kitchener, Ontario, is a leading manufacturer of thin film vacuum deposition equipment and vacuum chambers equipment. The company specializes in designing, manufacturing, selling and servicing machines that deposit thin films, growing layers of materials on a substrate with thicknesses that can range from less than one nanometer to several microns, the process has many applications in research and industry.

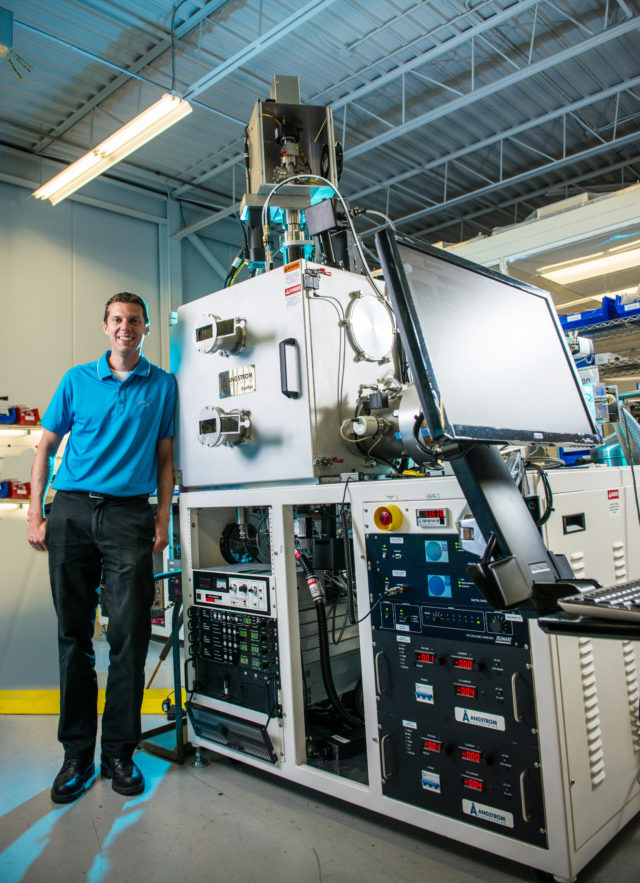

Angstrom’s president, David Pitts, proudly notes, “We are one of a few companies capable of producing the layered thin films on a nanometer scale in Canada.”

Although few people may be familiar with the thin film industry, its products are integral to our daily life. A pair of prescription eyeglasses has a physical vapour deposition (PVD) coating on it—the antiglare, anti-scratch coating on the surface of the eyeglasses is on the nanometer scale. Television and cell phone screens use similar technology.

“We design and manufacture the machines for thin-film coating, and our customers purchase machines from us and build different thin-film products for various applications,” says Pitts.

Besides the thin-film coating equipment, Angstrom also manufactures vacuum chamber machines for space simulation, allowing customers to simulate the space or satellite environment.

Most of Angstrom’s customers are researchers, universities and research laboratories across the world in the fields of material science, physics, chemistry and electrical engineering.

In order to ensure customers’ specifications are met, and because of the complexity of the end products, all of Angstrom’s products are engineered to order. However, this custom approach does not limit the company’s sales to market; Angstrom exports the majority of its products, and has delivered equipment to clients in over 34 countries on five continents.

Angstrom traces its roots to 1992, when Andrew Bass founded it as a small service company for vacuum manipulators and components. After eight years of hard work, Bass was able to hire the company’s first few employees and sold several PVD systems in 2000. Pitts was promoted to president after Bass’ retirement in 2011.

In 2009, Angstrom moved its whole team from Cambridge, Ontario to its current facility in Kitchener to meet the growing business needs and better serve its clients.

The company employs 35 staff members, with the team made up of engineers and skilled tradespersons.

Waterloo’s talent pool has been an excellent source of skilled workers for Angstrom. The company also hires many of its engineers from nearby Western University, the University of Toronto and Conestoga College.

Partnering with educational institutions and attracting skilled talents are important to Angstrom. Workers with skills in science, technology, engineering and mathematics (STEM) play an extremely important role in driving the company’s innovation and growth. Simultaneously, Angstrom works closely with universities on research, not only to fulfill its research and development (R&D) needs but also to better serve its clients.

Angstrom takes advantage of a wide range of available government programs; its internal R&D has been successful through the Industrial Research Assistance Program (IRAP) and the Scientific Research and Experimental Development (SR&ED) program, according to Pitts. In addition, the company has received the Natural Sciences and Engineering Research Council of Canada (NSERC) Engage Grant for a number of consecutive years. Down the road, Pitts is looking forward to applying for the Ontario Centres of Excellence (OCE) Voucher for Innovation and Productivity (VIP) grant.

When asked to define the one policy change that would help Angstrom attain greater success, Pitts replies, “Overall, we benefit a lot from working with all levels of government but there is some slight room for improvement— namely, opening up the border with America.” Due to the fact that there are a limited number of suppliers in Canada, Angstrom places approximately 2,000 orders a year from America. Each shipment then has to go through customs, which leads to extra costs, Pitts explains.

Even though it has few serious competitors in Canada, Angstrom is competing with leading U.S. and European companies globally. To keep business thriving and to stand out from the competition, Pitts emphasizes that Angstrom must continue to focus on customers’ needs, and remain responsive and customer friendly. “In addition, we are constantly improving our products and evaluating our methods of reaching customers in different markets,” adds Pitts.

Pitts is expecting the business to continue to grow. He foresees the R&D trends in emerging markets, and is looking forward to expanding Angstrom in this new environment.

For more information about Angstrom Engineering, visit their website.

Published: August 3, 2016

Transformix Engineering

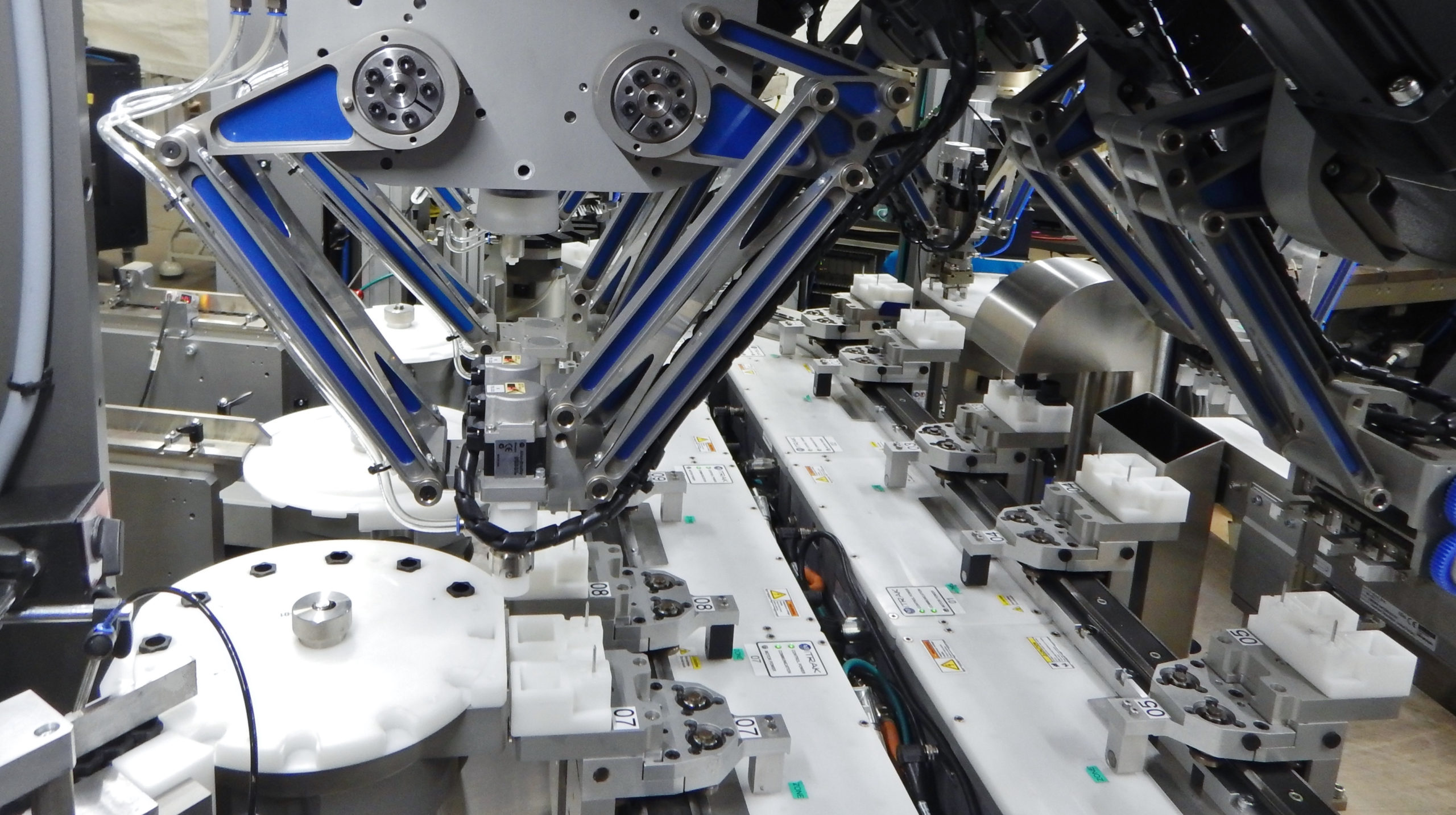

Transformix Engineering is exclusively focused on CNCAssembly® technology in the specialized niche of "continuous motion", and have developed it into a general solution for small-part assembly.

Givens Engineering

Givens Engineering Inc. designs and manufactures light cranes, manipulators and machinery for industrial use. The company specializes in lifting equipment and automated material-handling machines.

Parmerit Inc. | Wolfe Heavy Equipment

When selecting a product or service, manufacturing customers look for companies that can deliver high quality and expertise. Parmerit Inc. (Parmerit) and Wolfe Heavy Equipment (Wolfe), two manufacturing companies located in Strathroy, Ontario, are companies that clearly understand the needs of their customers. Not only do they offer technical expertise, they also have an ability to manage projects and products tailored to their customers’ specific needs.

BOS Innovations

BOS Innovations develops custom factory automation solutions to help companies reach greater levels of productivity and profitability. The company’s mission is to advance North American manufacturing through world class integration of automation systems with innovative engineering, build quality, and service.

Abuma Manufacturing Limited

Abuma Manufacturing Ltd (Abuma) is a Build-to-Print metal fabricator capable of manufacturing custom components. Abuma fabricates the metal components and upper-level assemblies and integrates additional outside services like surface coatings, electrical, pneumatics, and purchased equipment as required.