-

Headquarters -

65 Basaltic Rd, Concord, ON, L4K 1G4

-

Year established -

1972

-

NAICS -

335311 - Power, distribution and specialty transformers manufacturing

-

Major expansions -

2007, 2022

-

Employees -

289

-

Exports -

United States, Europe, Asia, Middle East

-

Download -

Rex Power Magnetics

Rex Power Magnetics specializes in manufacturing low to medium voltage, dry type power, distribution and specialty transformers. Bursting at the seams of its 145,000 square foot facility in Vaughan and preparing to celebrate its 50th year in business, the company employs 290 people and generates annual revenue of $85 million.

Oldsmobiles are long gone, but at least one part from a household name of Detroit auto making avoided the scrap heap. When off-the-shelf coil winding equipment used to produce transformer cores wouldn’t cut it, Rex Power Magnetics decided to improve the design. To the surprise of all, a brake caliper borrowed from an Oldsmobile Eighty Eight performed better in maintaining the wire tension than other more sophisticated and expensive components.

“Machines on the market had non-adjustable wire guide arms and that contributed to issues with wire tension and jolting; they were also difficult to service,” Ara Hasserjian, Rex’s general manager, says. Using a modified Oldsmobile brake caliper and rotor as part of the company’s own design was a simple but ingenious idea. “This works better, and it is easier to find and cheaper to maintain,” Hasserjian says. This type of simple but effective innovation has underpinned Rex’s steady growth over five decades.

Rex specializes in manufacturing low to medium voltage, dry type power, distribution and specialty transformers. It mainly serves the commercial and industrial markets for constructing buildings such as hospitals, schools, and transit infrastructure. Bursting at the seams of its 145,000 square foot facility and preparing to celebrate its 50th year in business, the company employs 290 people and generates annual revenue of $85 million.

[Designing our own machines] gives us the ability to customize [them] to our specific needs. It also reduces the cost of buying an off-the-shelf product with lots of unnecessary features.

On a tour of the company’s factory in Vaughan, Hasserjian proudly points at two other machines that Rex had custom built. These machines cut grain oriented electrical sheet steel–a key material with unique magnetic properties– into parts suitable for making transformer cores. Rex contributed to the conceptual and detailed design, pulling together with a North Carolina based machinery builder, as well as an automation specialist from India. One has been operating for 20 years and the other one – a much quieter and more efficient upgraded version – has been in operation for a few years.

When making investments in new production technologies, Rex often prefers designing its own machines. “This gives us the ability to customize machines to our specific needs. It also reduces the cost of buying an off-the-shelf product with lots of unnecessary features,” Hasserjian says. “This way we know what we are getting and how to maintain it, and we can control the cost of scaling up.”

Transformers are critical in every electrical network. Electricity travels from generating stations to its destination through complex transmission grids. Transformers are necessary to convert power to the appropriate voltage, providing isolation between sections of the grid. They also contribute to the overall safety and resilience of the network.

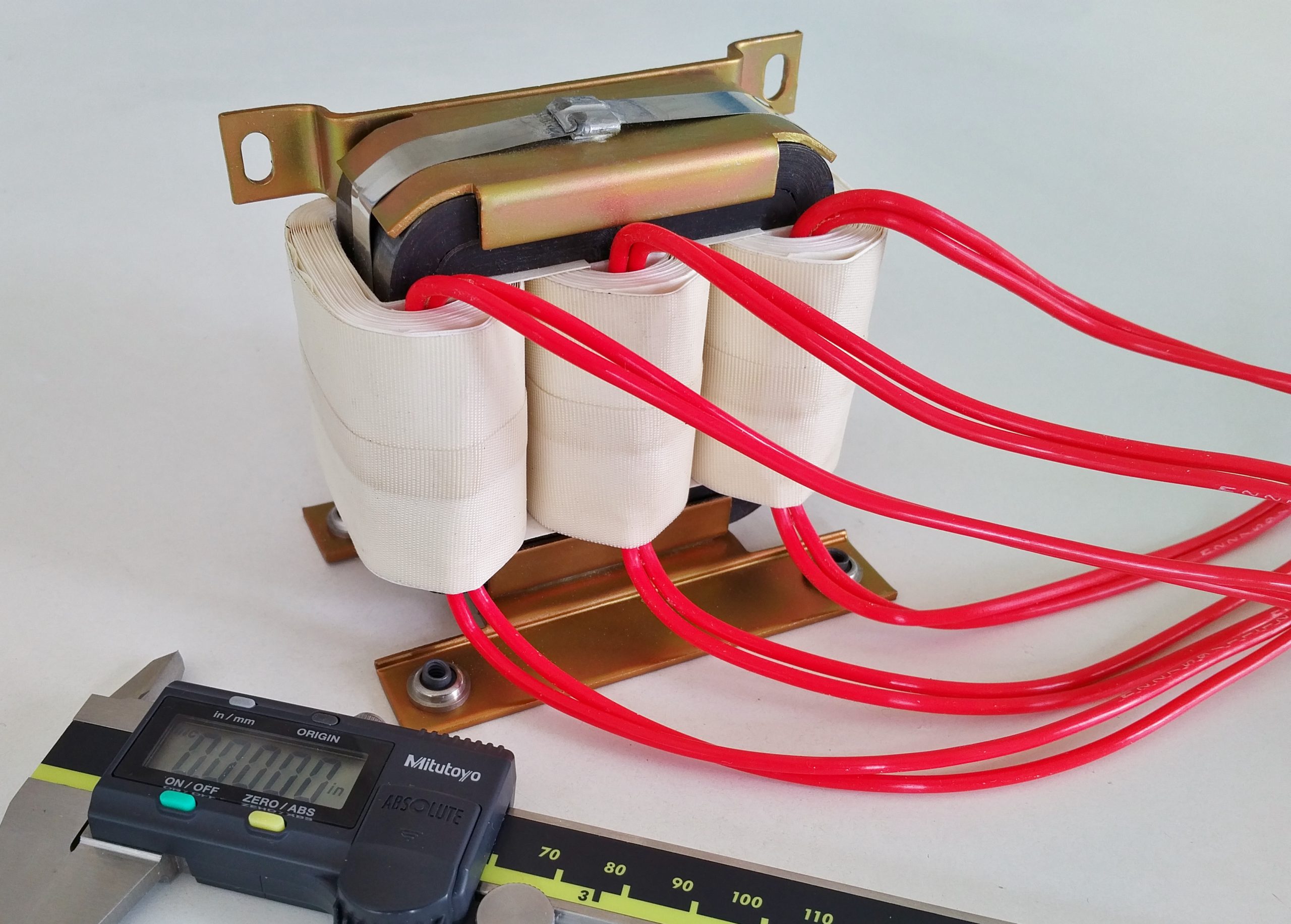

The dry type transformers that are Rex’s specialty use solid materials in combination with air as both a dielectric and a coolant rather than oil, which is what liquid-cooled transformers use. This makes these products more suitable for installations where low maintenance is critical, and the potential for oil leaks is problematic. They are also highly efficient with efficiencies typically around 98.5 per cent or better.

The One World Trade Center tower in New York, Humber River Hospital in North York, and Toronto subway system’s line 4 along Sheppard Avenue rely on Rex transformers.

Rex has grown tremendously since its inception in 1972. It is among the top three transformer suppliers in each Canadian province. The company also exports about half of its products to the United States and another 10 per cent to countries in Asia and the Middle East. The One World Trade Center tower in New York, Humber River Hospital in North York, and Toronto subway system’s line 4 along Sheppard Avenue rely on Rex transformers. These examples illustrate the high levels of safety, durability and quality standards synonymous with Rex’s products.

“Rex has humble beginnings,” Hasserjian says. In 1972, Manuel Viveiros, an immigrant to Canada, quit his job at a large transformer manufacturer to set up his own business. “Manuel believed that customers could be served better by a locally owned manufacturer that is responsive to their needs,” Hasserjian says. Hasserjian’s father, Simon, who was also an immigrant and a former colleague of Viveiros, joined the latter in 1985 as a business partner.

Throughout the 1990s, Rex expanded its customer base across Ontario. “Local machinery dealers supplying small shops and garages started to prefer Rex transformers,” Ara Hasserjian points out. “There was a gap in the market and Rex filled it – that was the first major growth phase.”

Transformers then were not as sophisticated and efficient as they are now, he says. “Only after regulatory authorities started setting higher efficiency standards in the early 2000s did the industry begin to really innovate.”

As Rex continued to grow, Viveiros and Simon Hasserjian were seeking someone to develop and support the sophisticated management and supply chain considerations that became more pertinent with scale. Ara Hasserjian’s uncle, Levon, was a vice president of a multinational corporation. Rather than following his role which was being moved to the United States, he decided to join his brother and Viveiros at Rex.

With the expertise brought by Levon Hasserjian, Rex grew steadily. The company started implementing a more structured growth plan, received its ISO 9001 quality management certification, and leased an additional building to meet increasing demand.

The management’s strategy that prioritizes stability and profitable growth involves multiple elements: incremental investments in automation to boost productivity, R&D projects for improved quality and broader product offerings, and continual investment in the development of its employees.

By 2000, Rex was generating revenue of more than $5 million annually. By 2015, it was up to $50 million. Ara Hasserjian notes that revenue is not the best measure of financial performance. “As material and labour costs increase, our products are sold at a higher price, too. We take great care to prioritize stability and profitable growth.”

As a result of this rapid growth, Rex needed more hands on deck. Ara Hasserjian’s brothers, Karnig and Raffi, have joined the company, and are involved with many aspects of projects and decisions that affect Rex’s further growth. They are supported by their father’s advisory presence and a strong and experienced management team.

The management’s strategy that prioritizes stability and profitable growth involves multiple elements: incremental investments in automation to boost productivity, R&D projects for improved quality and broader product offerings, and continual investment in the development of its employees.

We plan on deploying [new] systems in our new facility in Etobicoke, where we will focus on manufacturing more standardized and high-run products.

When making incremental investments in new equipment, Rex controls the cost of equipment by using its in-house design capabilities. The company has also collaborated with educational institutions to develop advanced production systems when in-house skills were not sufficient. A project with Sheridan College’s Centre for Advanced Manufacturing and Design Technologies (CAMDT) led to the creation of a robotic stacking system that automates the stacking of laminated pieces of electrical steel, which is otherwise a laborious and repetitive task. Another project with Centennial College led to the development of a robotic part collection system. Rex took advantage of the Scientific Research and Experimental Development (SR&ED) tax incentives and The National Research Council of Canada Industrial Research Assistance Program (NRC IRAP) to cover some of the costs related to these projects.

“We plan on deploying these systems in our new facility in Etobicoke, where we will focus on manufacturing more standardized and high-run products,” Hasserjian says. “We will also have the space to install these machines there.”

Finding a nearby industrial building to expand operations has been a major barrier to the company’s growth. Rex has used all available space at its current plant in Vaughan since 2018 and had no more room to add any new equipment. “Since 2020 we bid on more than 10 buildings but either got outbid or the building got taken off the market due to rapidly rising prices.” After two years of searching, Rex finally secured a 51,000 square foot building in Etobicoke.

Hasserjian offers a manufacturer’s perspective on the shortage of industrial land in Ontario. He notes that a lot of new building developments focus on meeting the warehousing demand in the region. That, coupled with a general industrial land shortage in Ontario and zoning policies that are difficult to modify, has been hampering growth of many manufacturers, he argues.

As the new facility expansion is underway, Hasserjian looks forward to better serving some of the fastest growing markets with more innovative products. In recent years, Rex has seen a surge in demand for specialty transformers used in data centres and renewable power generation.

These types of niche markets, often not served directly by larger manufacturers focused on making standardized products, are the most lucrative for Rex. To meet the needs of these markets Rex continually invests in product R&D and develops specialty products. For example the company developed its own design of cast coil and epoxy encapsulated transformers for use in harsh operating environments. Another product innovation focused on meeting the requirements of mobile natural gas extraction equipment. “More recently, our focus shifted to the renewable energy space,” Hasserjian says.

Every percentage point decrease in the transformer loss factor can create massive energy savings when you consider all the transformers connected to the entire grid.

On the topic of climate change, Hasserjian points out that transformer efficiency is critical to lowering greenhouse gas emissions. “Every percentage point decrease in the transformer loss factor can create massive energy savings when you consider all the transformers connected to the entire grid.” However, he underlines that regulations are key to driving further efficiencies in transformers. The typical customer for transformers is the development industry and for them, cost is the primary concern. Hence they seldom want to pay more to invest in a more efficient transformer. Only if regulators follow past practice of raising the minimum required efficiency levels for transformers will substantial energy savings be generated, Hasserjian says.

While demand remains strong for Rex’s products, supply chain related issues have created headwinds. Material costs have been rising and Rex had to absorb some of these to avoid upsetting its customers. To avoid that in the future, the new contracts Rex negotiates include provisions such as price indices for material costs to protect the company’s bottom line.

Even then, some critical materials such as grain oriented electrical steel have become harder to source. Russia was a major supplier to the global market for this type of steel so its invasion of Ukraine has affected the market. Rex and others have shifted demand to suppliers in the United States, Europe, and Asia. The company communicates any delays in obtaining materials with its clients proactively to mitigate any adverse effects.

We have been fortunate to have truly excellent, dedicated, and talented personnel as employees, throughout our growth, and also certainly at present.

Despite ongoing supply chain challenges, Rex is growing. A core factor enabling that growth is Rex’s talented personnel. “We have been fortunate to have truly excellent, dedicated, and talented personnel as employees, throughout our growth, and also certainly at present,” Hasserjian says. He points out that dozens of Rex employees have been with the company for over 20 years and some for 35 years.

The company has also been working with COSTI Immigrant Services based in Toronto for many years. It hires newcomers and refugees as an answer to ongoing skilled labour shortages in Ontario. During the civil war in Syria, for example, the company welcomed 43 refugees. Many have stayed with Rex. Today, of the 290 employees at Rex, about 45 were newcomers to Canada when they started to work for the company.

Our company owes so much to the hands of skilled winders, passionate and methodical assemblers, organized and empathetic supervisors, considerate and kind customer facing personnel, and experienced electrical designers.

“Many newcomers we hire already have a considerable amount of skills they need to succeed at Rex,” Hasserjian says. “We provide additional on-the-job training to help them adapt their skills to their new jobs,” he adds. And training does not end there. Rex management believes that each person can achieve higher levels of productivity when trained. This is a source for boosting the company’s overall profitability. And in turn, through a profit sharing program, employees benefit from increased profitability.

“Our company owes so much to the hands of skilled winders, passionate and methodical assemblers, organized and empathetic supervisors, considerate and kind customer facing personnel, and experienced electrical designers.”

For more information about Rex Power Magnetics, visit their website.

Published: November 2, 2022

Northern Transformer

Transformers are a key component of electrical infrastructure

Electronic Craftsmen

Electronic Craftsmen is a custom designer and manufacturer of specialty transformers, inductors, chokes, and reactors for use in power electronics applications.

Mircom Group

Building on the past, planning for the future, while reacting to today’s challenges are keys to Mircom’s success.