-

Headquarters -

469 Silver Creek Industrial Dr, Windsor, ON, N8N 4W2

-

Year established -

1976

-

NAICS -

333248 - All other industrial machinery manufacturing

-

Major expansions -

2018

-

Employees -

200

-

Exports -

United States, Mexico, China, Middle East

-

Download -

Reko International Group

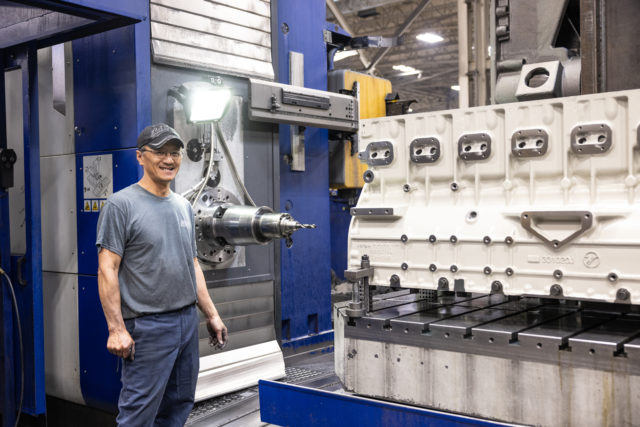

On the shop floor of Reko International, two monumental machining centres stand silent witness to the company’s legacy, resilience, and innovation.

Dubbed in their Hungarian names which translate into bear and bull, these 15 metre tall machine tool artifacts symbolize the company’s evolution from a small automotive mould shop into a diversified and technology-driven automation and machining company. They also keep alive the legacy of Steve Reko, who founded the company in 1976.

Reko International is a diversified, technology-driven manufacturing organization that employs 200 people at its three side-by-side buildings in the Windsor suburb of Lakeshore. The company is organized into two divisions, focusing on automation systems and precision machining of large critical parts. The automation division specializes in plastic welding technologies primarily for the automotive industry and it has been the fastest growing segment of the company thanks to its recent innovations in flexible automation.

It is too big of a risk not being able to manufacture things here in Canada - especially, as we’ve seen recently, during times like a global pandemic.

“We are here to help other manufacturers succeed,” Diane Reko, Reko International’s chief executive officer, says in describing the company’s role in Ontario’s manufacturing ecosystem. “It is too big of a risk not being able to manufacture things here in Canada – especially, as we’ve seen recently, during times like a global pandemic,” Reko says.

Reko International’s evolution from a small mould shop into a technology-driven automation company serving global customers is another success story from Windsor’s strong tool, mould and automation cluster. Primarily serving the automotive, power generation, transportation and aerospace industries, Reko International has completed a multitude of projects for customers in Canada, the United States, Mexico, China, and the Middle East. Often, its global customers ask the company to deliver projects for their plants located in different parts of the world.

Diane Reko says the most important contributor to the company’s success has been its dedicated and innovative workforce. As the company looks ahead to a technology-driven future, a skilled workforce that can overcome the challenges inherent to the complex projects it takes on remains as the most vital asset for the company.

Reko International traces its roots back to Windsor's legendary International Tools Limited (ITL), which is often credited for birthing the city's renowned tool and mould cluster.

Reko International traces its roots back to Windsor’s legendary International Tools Limited (ITL), which is often credited for birthing the city’s renowned tool and mould cluster. ITL was established in 1945 by Peter Hedgewick, putting Windsor on the map for mould making. When Steve Reko emigrated from Hungary to Canada in the 1950s he had little more than the clothes on his back and his training as a machinist. That got him a job as a machinist at ITL, where he worked alongside other skilled immigrants from Europe for about two decades.

In 1976, with the confidence and knowledge developed while working at ITL, Steve Reko founded his own company. He rented a 2,000 square foot unit in an industrial park of EC Row Expressway. At first, his company, known as Reko Tool and Mold, focused on making automotive moulds for plastic interior automotive components. The company entered the machine building business in the 1980s, taking advantage of Steve Reko’s keen interest in how machines worked. That kick-started the company’s diversification from being only a mould manufacturer into a technology-driven automation company. In the 1990s, amid booming automotive industry, the company entered a major growth phase. Amid this growth, Steve Reko wanted to implement a grand plan to grow Reko International even further.

“My father’s vision was perhaps a bit ahead of his time,” says Diane Reko. That vision foresaw a centralized engineering team and production centres located at the doorstep of automotive assembly plants in the midwest United States. As part of implementing this plan, Reko went public in 1994 to raise the necessary capital.

While Reko International’s Automation division primarily serves the automotive industry, Concorde supplies a multitude of industries that are not necessarily consumer-facing. That provides the company a healthy cash-flow and diversified markets to weather the cycles of the automotive industry.

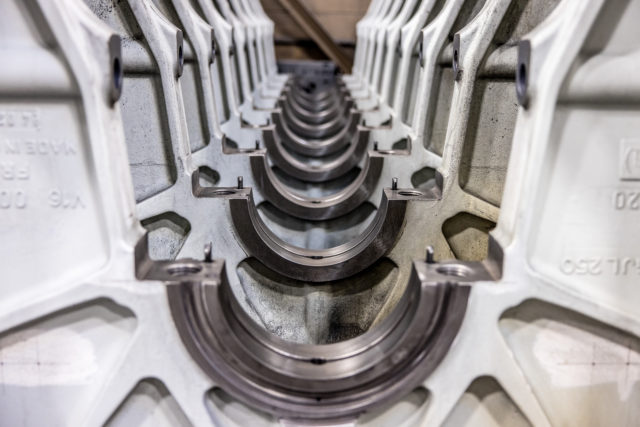

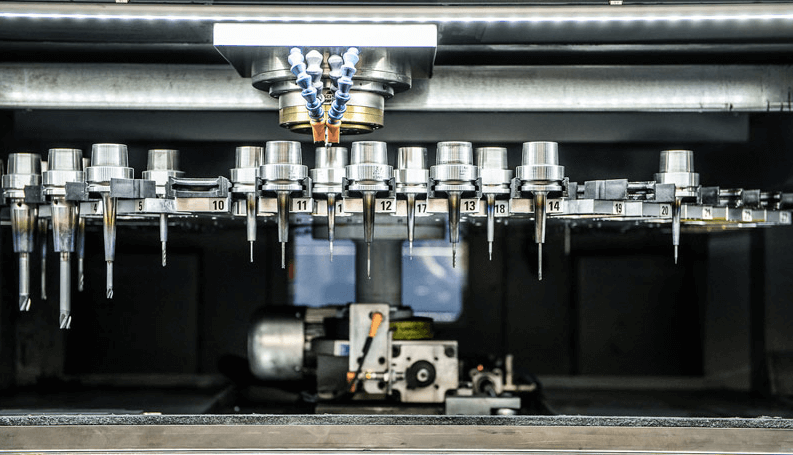

Also in 1994, Reko International acquired Concorde Precision Machining, one of the company’s customers in the area. Concorde, whose founder worked for a supplier of aircraft parts to the Concorde supersonic airliner, is a highly specialized machine shop. It provides high precision, custom machining of large scale castings, forgings, assemblies, and fabrications. Its customers range from power generation companies to locomotive manufacturers. Concorde was the home of the colossal machining centres (the bear and the bull) built by Steve Reko prior to the acquisition.

While Reko International’s Automation division primarily serves the automotive industry, Concorde supplies a multitude of industries that are not necessarily consumer-facing. That provides the company a healthy cash-flow and diversified markets to weather the cycles of the automotive industry.

Despite diversification, Reko International was severely affected by the collapse of the automotive industry during the 2008-09 financial crisis. The company had to make the difficult decision to shutter some of its facilities in Oldcastle.

“That was a really challenging time and the restructuring was the most difficult decision I had to make,” Diane Reko says, who took over the leadership role after her father passed away in 2007.

The early 2010s were a time of financial challenges, but the company emerged stronger. Diane Reko points to a strong balance sheet as insulation from global economic headwinds.

Reko International has also made a strategic pivot away from the legacy mould business since the financial crisis, focusing its efforts on growing its automation division. That was driven in part by the increasing level of offshore competition from lower-cost competitors in China and Czechia. The company has also identified new opportunities for value-added growth in automation technologies.

The flexible automation systems allow OEMs and Tier 1s to manufacture multiple different variations of a component on the same equipment without sacrificing cycle time.

One opportunity emerged in automotive fascias, which have become more complex. Automotive OEMs and Tier 1 suppliers have been in search of innovative solutions to manufacture these increasingly complex components that incorporate more electronic parts and sensors more efficiently. In response, Reko’s engineers have developed flexible automation systems.

The flexible automation systems allow OEMs and Tier 1s to manufacture multiple different variations of a component on the same equipment without sacrificing cycle time. Reko uses robots and innovative design features to achieve this. Its systems have already been deployed at suppliers to luxury car assembly plants in the southern United States where components often have a high-mix, lower volume nature.

Projects in flexible automation have become a key source of growth for Reko over the past two years. Diane Reko expects this trend to continue as the automotive industry transitions towards making more electric vehicles (EVs). During this transition, internal combustion engine vehicles and EVs will both be manufactured. Flexible manufacturing will be necessary to help maintain productivity and profitability.

In addition, reducing energy consumption and waste will be necessary to make manufacturing more sustainable. Reko believes flexible automated manufacturing systems can reduce energy consumption by eliminating the requirement to run certain lines or have machines idle in a high-mix product environment. They also eliminate the need to purchase new equipment as similar operations can be handled as effectively and efficiently as by a single automated flexible manufacturing system.

Finally, flexible production systems can lower the demand risk for manufacturers. When orders of a particular version of a component differ from what was forecast, the system can simply be adjusted to handle the new volumes.

Automotive is a challenging market. If you haven’t worked in it, it can be daunting to start. But if you can tough it out there you can do it anywhere.

“Automotive is a challenging market. If you haven’t worked in it, it can be daunting to start. But if you can tough it out there you can do it anywhere,” Diane Reko says. She believes that Reko’s capabilities and experiences are transferable to other industries.

Having its roots in serving the automotive industry, which demands high levels of quality and precision, has also earned Reko the confidence to bid on projects in other industries with stringent quality and precision requirements. Growth in its aerospace business is an example.

“Aerospace companies are constantly looking for innovative ways to improve their production processes,” Diane Reko says. “Reko’s team of engineers, skilled technicians, and designers are able to offer innovative solutions that these companies appreciate.”

Mining, bakeries, and construction are other target industries. The company has also been trying to diversify into medical devices, although this process was interrupted during the COVID-19 pandemic. Due to travel restrictions, for example, a major project installation had to be outsourced to a competitor in the United States. Reko would like to support these other industries with automation equipment so that North America can maintain its production and manufacturing and thus independence around these areas.

Everyone wants to know if you’ve built something for their industry before–that first project will be difficult but once that is done, it becomes easier to convince new customers that you are capable.

Speaking of expanding into new industries, Diane Reko notes that the first sale is always the hardest. “Everyone wants to know if you’ve built something for their industry before–that first project will be difficult but once that is done, it becomes easier to convince new customers that you are capable.”

She further notes that starting with bidding on smaller projects is generally a plausible strategy. “But it is important to try to use that small project to show the customer something innovative, like a modular production system, so they see the advantages of working with us.”

While there are many growth opportunities, Reko’s plan to bid on and deliver more projects depends on its ability to recruit and retain talent. The company’s efforts to improve diversity and inclusion as well as employee training and development play an important role here.

You can hire but have to work on inclusion... People need to feel welcome.

“You can hire but have to work on inclusion,” Diane Reko says. “People need to feel welcome.” She notes that there is always more work to be done on this. Reko recently invested in a new software called SocialSuite to measure and report on its impact and ESG. The software has guided Reko’s management on how to document, measure, and monitor the impact of the company’s ESG initiatives, including efforts to improve diversity and inclusion.

Reko has been a certified member of the Women Business Enterprises Canada (WBE Canada) since 2010. While the initial motivation to get certified was business-oriented – the automotive industry’s push to increase business with minority suppliers – Diane Reko soon saw the power of these networks. “It is not just a certification – it is also something that makes people applying for jobs more interested in the company.”

Nevertheless, Reko is not immune to the wider challenges of finding new talent. “The situation is not new. My father also used to go to meetings at St. Clair College to discuss solutions for recruiting skilled trades personnel,” Diane Reko says. She says that now, at least, there is a chance to replace jobs that can be dangerous, repetitive, and difficult with more automation.

A customer wants to double its order right now but to train the personnel to increase production capacity takes many months.

Human talent is still essential, however, and Reko needs more machinists, engineers and other skilled trades professionals, who are often not easy to find. As a result, Reko hires many people with little experience and invests in their development. The company assists the most enthusiastic and mechanically-apt personnel to pursue training in skilled trades by providing them tuition reimbursements and opportunities to learn on the job. Despite the program’s success, there are also some risks. For example, sometimes people leave after they complete their training or choose to pursue a career in a field not aligned with the company’s needs.

Hiring can be difficult but training is where the most time is spent. “A customer wants to double its order right now but to train the personnel to increase production capacity takes many months.”

To shorten training times, Reko is experimenting with new technologies such as augmented reality. A recent pilot program will deploy Microsoft HoloLenses to train forklift and crane operators. The company is in the process of measuring whether this approach improves job performance and training outcomes.

Reko’s efforts to address recruitment challenges are effective only to a certain extent. For example, lack of public transportation from Windsor to the industrial area where Reko is located near Patillo Road limits the company’s ability to reach more diverse groups of people living in other parts of Windsor who do not have personal transportation.

The lack of public transit to the Lakeshore area is not new and according to Diane Reko, it needs to be addressed in the near future. The industrial area near Patillo Road and Highway 22 is home to such large manufacturing plants as Magna Integram Seating, Vistaprint, Dakkota Integrated Systems, TRQSS, and Can Art Aluminum Extrusion. Whether the solution involves Transit Windsor or a local option is not clear. However, bus service from Windsor to LaSalle, Leamington, and Amherstburg have all begun in the past several years. That means, a solution could be possible in Lakeshore too.

Availability of a public transit system becomes even more essential as global companies plan to open up new large manufacturing plants in the region. New manufacturing investments in the region are commendable but they also put pressure on an already tight labour market. A public transit infrastructure could support local companies’ efforts in talent recruitment and retention.

What is really important for us is making sure we can manufacture and produce things in Canada.

Additionally, global companies setting up shop in the region may be reluctant at first to work with local companies. The reason might be that these companies just want to leverage their existing supply chains located elsewhere or a lack of local know-how. Building connections between local companies and the new arrivals and supporting them in developing the desired capabilities may be key to unlocking additional economic benefits.

Despite some challenges, Diane Reko sees opportunities to grow in the future and she is hopeful about the future of her company. “What is really important for us is making sure we can manufacture and produce things in Canada.”

For more information about Reko International Group, visit their website.

Published: February 2, 2023

CenterLine

CenterLine is a manufacturer of custom automated welding and assembly lines, as well as resistance welding-related products. The firm is known worldwide as a leader in fastener welding technology, which is used in the production of automotive components.

Laval International

Located in Windsor, Ontario, Laval International (Laval) manufactures production-ready moulds and composite parts for a wide range of industries. In addition to manufacturing, Laval offers engineering and prototyping services to customers seeking turnkey solutions. International presence can be attributed to its commitment to providing customers with the most technologically advanced and effective products.

Cavalier Tool and Manufacturing

“Understand what needs to be done. Do it right the first time. Do it better tomorrow.” These are the words that have guided Tim Galbraith and Darcy Urquhart, Sales Managers at Cavalier Tool and Manufacturing (Cavalier) over the last three decades.