-

Headquarters -

265 Watline Avenue, Mississauga, ON, L4Z 1P3

-

Year established -

1984

-

NAICS -

325410 - Pharmaceutical and medicine manufacturing

-

Major expansions -

2018

-

Employees -

90

-

Exports -

Americas, Europe, Middle East, Asia-Pacific, Africa, Oceania

-

Download -

Microbix Biosystems Inc.

Microbix is a biomanufacturer of antigens used in infectious disease diagnostic tests. The company has been a critical component of Ontario’s life sciences ecosystem since 1984.

Even those intimately familiar with advanced manufacturing are likely unfamiliar with the elaborate processes used to produce antigens, critical ingredients of many diagnostic tests. Microbix Chief Executive Officer Cameron Groome compares viral antigen manufacturing to “hitting a bullet with a bullet while riding a horse,” emphasizing the scientific expertise required. The ability of Microbix to work at this level of complexity has made the company a key asset for Ontario and Canada during the COVID-19 pandemic.

Antigens are substances such as the proteins of bacteria and viruses that prompt the human immune system to produce antibodies in defense. Antibodies attach to antigens, which make antigens a critical component of medical diagnostic tests that detect exposure and immunity to pathogens. For instance, if a blood sample contains antibodies that attach to specific antigens in a medical diagnostic test, the test result would be positive.

Microbix’s goal was to transform itself from a maker of unbranded, lower value-added antigens into a producer of higher value-added, innovative, proprietary, and branded medical devices.

Producing viral antigens starts by growing host mammalian cells that are then infected with live virus. Once the host cells have enabled the production of enough virus, cell residue and culture media (cell food) are removed, leaving just the target antigenic virus particles. Next, the purified viral antigens are inactivated, meaning they can no longer reproduce. In each step, Microbix employees use a variety of biological techniques that have been perfected by the company over decades.

Microbix’s antigens are used by more than 100 leading international diagnostics companies. Prior to the pandemic, the company exported all of its products directly and through a distributor network, generating $1 million of revenue on average per month. All antigen production takes place at Microbix’s 14,000 square foot manufacturing facility in Mississauga. A 10,000 square foot site nearby houses the production of the company’s other product lines as well as some warehousing and logistics operations. Microbix employs 90 people across these two locations. Many staff members hold advanced degrees in molecular biology, virology, and other related life science disciplines.

When the COVID-19 outbreak emerged, the importance of a strategic shift Microbix began in 2017 became clear. The company had launched its quality assessment products (QAPs) used for verifying the accuracy of infectious disease diagnostic tests, unaware of the eventual pandemic. Microbix’s goal was to transform itself from a maker of unbranded, lower value-added antigens into a producer of higher value-added, innovative, proprietary, and branded medical devices. When demand for testing surged with the pandemic, that strategic shift proved to be even more valuable. Within weeks, the company was able to launch specialized QAPs to help verify the accuracy of COVID-19 tests used across Canada.

The QAPs manufactured by Microbix emulate real patient samples so that diagnostic test manufacturers and clinical laboratories can use them to ensure their tests return accurate results. Consequently, these products help reduce the number of false test results which is especially crucial during this pandemic as many decisions are based on test outcomes. For example, false positives can drive unnecessary lockdowns and false negatives can put more people at risk of infection.

Specifically, no one in Canada produced viral transportation media (VTM), a liquid solution that keeps viruses in patient samples obtained with a swab at collection sites stable until they reach clinical laboratories. If global supply chains were disrupted and Canada did not receive enough VTM, that would halt COVID-19 PCR testing.

While QAPs are a fast-growing product line for the company, as of its first quarter of fiscal 2021 (Q1 2021) Microbix still generated about 70 per cent of its revenue from the production of infectious disease antigens. However, because QAPs contain antigens, the company achieves efficiencies from manufacturing both products in-house. More importantly, within QAPs the equivalent amount of antigens can generate about 100 times more value when antigens are sold to diagnostic companies as test ingredients. Notably, Q1 2021 revenues from the QAPs product line grew more than 35 times from the year preceding the pandemic and the company expects it to be one of the key drivers of future growth.

Beyond QAPs, Microbix’s more than three decades of biomanufacturing expertise offered another opportunity to help Ontario and Canada during the COVID-19 pandemic. As production, transportation, and trade of critical goods started to experience disruptions around the world, Microbix management identified a key product that the company could manufacture locally to help Canada avoid a potential testing bottleneck.

Over the years, Gastle created an Ontario-based reservoir of life sciences expertise, the importance of which is being demonstrated during the current pandemic.

Specifically, no one in Canada produced viral transportation media (VTM), a liquid solution that keeps viruses in patient samples obtained with a swab at collection sites stable until they reach clinical laboratories. If global supply chains were disrupted and Canada did not receive enough VTM, that would halt COVID-19 PCR testing. Anticipating this, Microbix management approached the provincial government with a plan to manufacture VTM locally, and in October 2020, the company was awarded $1.45 million from the Ontario Together Fund (OTF) administered by the Ministry of Economic Development, Job Creation, and Trade (MEDJCT) to support these activities. Microbix used this funding to build semi-automated production lines capable of manufacturing 600,000 units of VTM per month – enough to provide for 40% of Ontario’s current needs. The company’s ability to supply this product locally minimizes the risk of a potential disruption of COVID-19 testing.

While Microbix has proven to be a critical asset during the COVID-19 pandemic, its history extends back nearly four decades. The company was founded in 1984 by William (Bill) Gastle, a virologist by training. Gastle’s father was a doctor who served the Lakefield community and studied local bacteria and virus strains for such diseases as measles and rubella. Inspired by his father’s work and his own studies, Gastle founded Microbix with the goal of manufacturing the culture medium used for growing microorganisms in laboratories.

Public health laboratories then approached Microbix and entrusted it with growing bacteria and viruses on their behalf. The expertise developed growing bacteria and viruses led to contracts with infectious disease diagnostic test manufacturers in Canada and abroad. In 1990, he took the company public (TSX: MBX) but stayed on its management and board until his retirement in 2020. Over the years, Gastle created an Ontario-based reservoir of life sciences expertise, the importance of which is being demonstrated during the current pandemic.

Microbix expects sales to nearly double in fiscal 2021 from its fiscal 2020 levels and to redouble in fiscal 2022 (Microbix has a September 30 fiscal year-end).

Because Microbix operates in a fast-paced and high-tech industry, it needed to invest in automation and new production techniques to remain competitive. In the past, the entire antigen production process took place in large incubation rooms and mostly involved manual work. The ability to monitor processes and find deficiencies was limited until the final product was made. This reduced production efficiency and increased costs. To overcome this challenge, Microbix invested in state-of-the-art bioreactors that automate much of the viral antigen production process and even allow employees to track batch progress through their smartphones. Groome notes that automation offers greater rewards when applied to manufacturing higher-volume and standardized products like VTM and QAPs. Automating shorter production run products that require custom labeling, for instance, does not offer the same rates of return on that investment.

Groome emphasizes that timing is important in implementing successful automation projects: “You can’t be too early automating production for a new product because that new product may become obsolete before its widespread market uptake. You also can’t afford to be late because your competitors would get ahead of you. The sweet spot is somewhere in the middle.” He adds that having the right mix of skills within Microbix’s management team (including individuals with scientific, financial, and communications backgrounds) has helped the company get the timing right when implementing new production technologies.

In the past, Microbix became distracted with projects outside of its financial or operational reach. Devoting resources to those projects instead of in-scope R&D or automation risked leaving the company behind its competitors. The company has since learned to better align its goals with its core capabilities and resources, meaning that it has re-focused on its expertise for manufacturing products relating to infectious disease testing. That, coupled with plant modernization, production scale-up, and the launch of higher value-added and proprietary products, has placed it on a rapid growth trajectory. Microbix expects sales to nearly double in fiscal 2021 from its fiscal 2020 levels and to redouble in fiscal 2022 (Microbix has a September 30 fiscal year-end).

Microbix benefits from having a diverse workforce. Some positions require extensive technical skills and regulatory reporting experience. For those roles, the company hires individuals who demonstrate both scientific knowledge and strong communication skills. Other roles require very specific scientific knowledge and quality control experience. Recruiting individuals with the right combination of skills and education is important for Microbix and having a well-developed network of world class universities in Ontario supports the company’s efforts.

While many employees at Microbix hold advanced degrees in life sciences, there are also manufacturing technicians, as well as maintenance and logistics personnel who ensure production runs smoothly. Tight labour markets for such experienced personnel in the GTA can make it difficult for Microbix to retain some of these individuals. Microbix’s growth and the career opportunities that growth provides for staff are helping to address this issue. Despite this challenge, Microbix believes Ontario has an excellent workforce overall, with talented individuals from diverse backgrounds whose knowledge has been crucial in bringing the company to where it is today.

The pandemic presented Microbix with both opportunities and challenges. On one hand, the company launched new products, diversified its product line, and supported Canada’s efforts in developing a secure local supply chain for critical biological products. At the same time, sales of some of its key products from the pre-pandemic era fell as testing for other infectious diseases declined due to patients avoiding non-COVID-19 medical care. However, the company believes this to be temporary because non-COVID-19 infectious disease testing remains important for public health. Some cancers, for example, stem from infection with certain viruses and testing is key for early diagnosis and more effective treatment.

From its humble beginnings more than three decades ago, Microbix has emerged as a critical component of Ontario’s life sciences ecosystem. The ability of Groome and his team at Microbix to overcome challenges and capitalize on opportunities prompted by the pandemic is a testament to the entrepreneurial and innovative spirit espoused by Microbix.

Published: May 4, 2021

Jones Packaging

Jones Packaging is an international manufacturer of printed and contract-packaging and medical dispensing and delivery.

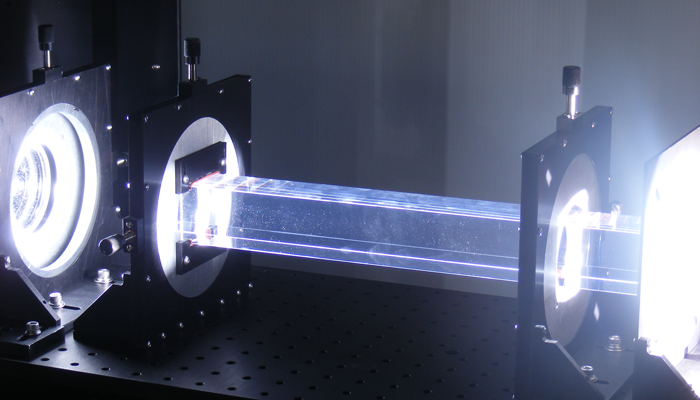

Sciencetech

Sciencetech designs and manufactures optical spectroscopic instruments, which are utilized across a wide range of industries and applications.

Proto3000

Based in Vaughan, Proto3000’s design, additive manufacturing, and metrology technologies help customers solve complex engineering and manufacturing challenges, resulting in shorter cycle times, more flexible supply chains, faster prototyping and more efficient production.

Kinarm

Kinarm is transforming the assessment of brain injuries by putting cutting-edge robotics technology into the hands of neuroscientists and clinician-scientists around the world.