-

Headquarters -

140 Railway Street, Kingston, Ontario, K7K 2L9

-

Year established -

2004

-

NAICS -

334512 - Measuring, medical and controlling devices manufacturing

-

Major expansions -

2009, 2013

-

Employees -

8

-

Exports -

US, EU, Japan, Australia

-

Download -

Kinarm

Kinarm is transforming the assessment of brain injuries by putting cutting-edge robotics technology into the hands of neuroscientists and clinician-scientists around the world.

Situated in the heart of Kingston, Ontario’s old industrial area, filled with construction contractors and bakeries, BKIN Technologies Ltd. (BKIN) blends into the surrounding landscape. From the outside, BKIN seems like a typical corporate office space; however, what happens inside the facility is nothing short of extraordinary. Led by president and chief executive officer, Anne Vivian-Scott, BKIN competes in the complex and fascinating world of medical robotics.

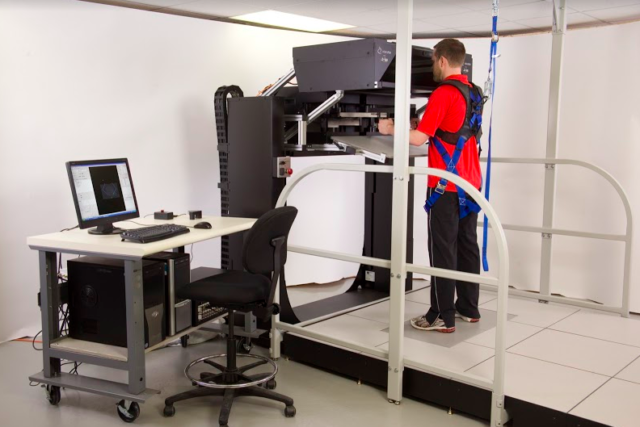

Long before BKIN was established, Dr. Stephen Scott developed the firm’s flagship technology—KINARM Labs—at the Centre for Neuroscience Studies at Queen’s University. As the world’s first robotic system for objectively measuring the effects of brain injuries (e.g., strokes, concussions, fetal alcohol syndrome, etc.) while performing ordinary movements, the KINARM technology was widely celebrated; demand for the technology quickly exceeded the lab’s capacity, resulting in a need to commercialize the product.

With an aversion to venture capital, BKIN needed to find another source of funding. In 2009, the company received funding from PARTEQ Innovation’s Venture Fund—an organization dedicated to developing Queen’s innovations and with whom they had co-founded the company. In 2013, BKIN moved into a vacant 3,500 square feet facility on Railway Street in Kingston, Ontario. This was a welcome change for Vivian-Scott and her staff because it centralized all BKIN employees under one roof.

Unlike many other areas of medicine, neurological practice lacks a “gold-standard” technology for assessing brain injuries.

Currently, physicians resort to questionnaires and visual inspection of patients’ behaviour. Without a system to quantify sensory-motor-cognitive deficits, it is difficult to accurately identify the underlying impairments and hence plan patient-specific rehabilitative care. With this shortcoming in mind, BKIN looked to revolutionize the way the clinical research community assesses brain injuries, by developing robust platforms for sensory, motor and cognitive assessment.

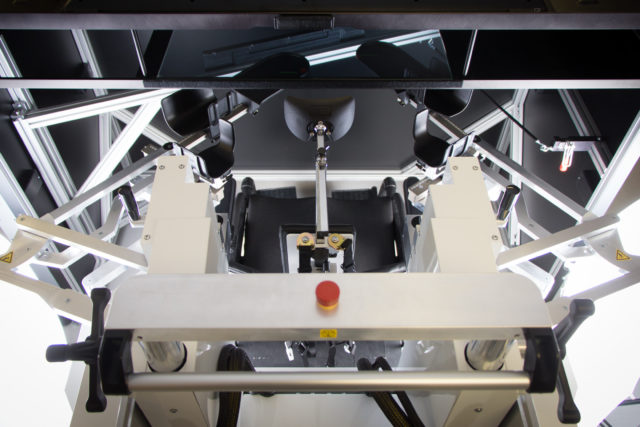

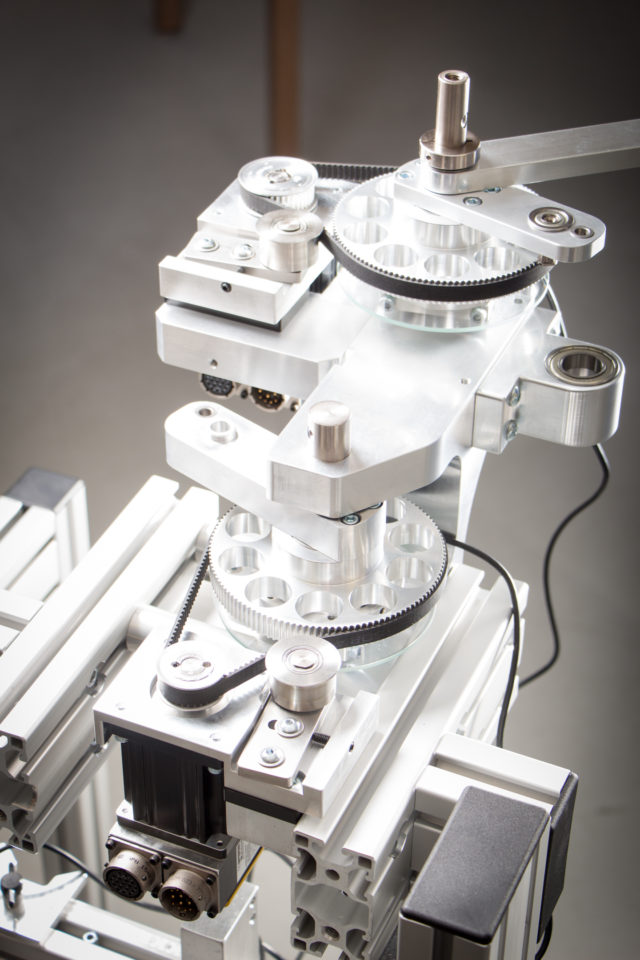

Building upon the original KINARM technology, BKIN developed and manufactured two distinct platforms: KINARM Exoskeleton Labs (Exoskeleton) and KINARM End-Point Labs (End-Point). Of these two platforms, the Exoskeleton robot was more complex, providing feedback from and control of the shoulder and elbow joint, as well as gravity support to the arms (the subject is seated). By focusing on manufacturing high-quality products, BKIN differentiated itself from its competitors.

With $1.5 million in revenues in fiscal year 2015, BKIN maintains strong relationships with Canadian and foreign researchers (e.g., motor control scientists), neuroscientists, and research hospitals. If it were not for the firm’s manufacturing constraints, Vivian-Scott believes that its sales would have been closer to $2 million this year. Historically, BKIN has achieved 5 per cent annual sales growth; however, this is expected to increase to 10 to 20 per cent in future years.

Exports make up over 60 per cent of BKIN’s earnings—a figure that is especially impressive in light of the firm’s smaller size.

BKIN exports to the United States, Japan, Australia, and many European countries. In 2016, the company closed a major deal to support a clinical trial of a pharmaceutical company.

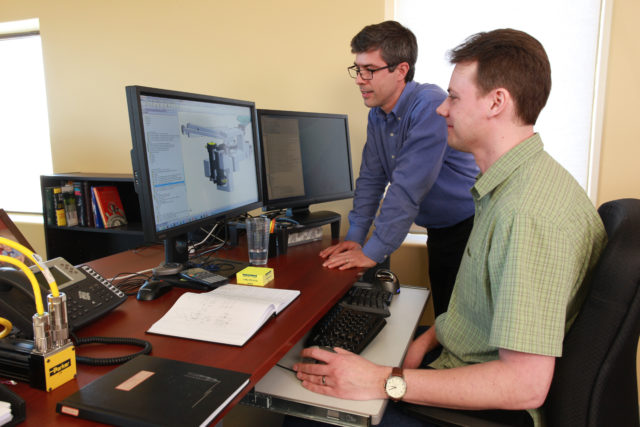

Given the industry’s need for regulatory compliance, the complex nature of its robotic platforms, and the firm’s small size, BKIN’s employees need to be well educated and trained. All seven of the firm’s employees have post-secondary education (ranging from college to university), and specialize in physics, software development, engineering, and/or manufacturing technology. As a smaller firm, BKIN uses word-of-mouth advertising and hires primarily from the Kingston area.

BKIN has encountered a number of challenges so far, such as compliance, a complex certification process, and determining how to pre-market its products. Despite these hurtles, Vivian-Scott and her colleagues remain devoted to ensuring that BKIN’s robotic platforms become essential pieces of diagnostic equipment in the years to come. If the firm continues to innovate and maintain a low cost structure, there is no reason it cannot accomplish its long-term goal: to become an essential diagnostic equipment supplier in Canada.

Update:

In 2019, the company was renamed from BKIN Technologies to Kinarm, and all manufacturing takes place in Kingston.

For more information about Kinarm, visit their website.

Published: September 26, 2016

Sciencetech

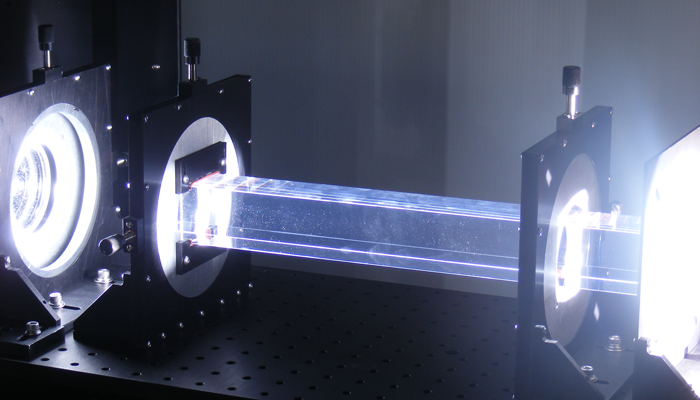

Sciencetech designs and manufactures optical spectroscopic instruments, which are utilized across a wide range of industries and applications.

RBR Ltd.

RBR designs and manufactures innovative oceanographic instruments that satisfy customer budgets and applications. The company offers sensors capable of tracking various water parameters, data loggers, and a variety of accessories for its products.

Parsons ADL

Located in New Tecumseth, Ontario, Parsons ADL is a manufacturer of home health care products. The company strives to create innovative solutions that will help improve the quality of life for the ageing population, as well as individuals with disabilities.

Giatec Scientific

Giatec Scientific manufactures concrete testing and analyzing solutions, enabling the wireless monitoring of concrete properties, accurate condition assessment of infrastructure, and durability-based quality control of concrete.

OZ Optics Ltd.

OZ Optics designs and manufactures advanced fiber optic components and test equipment for various fiber optic markets. The company implements rigorous quality standards to achieve its goal of providing all customers with a competitive advantage, and has become a leading worldwide supplier of optic products.