-

Headquarters -

2236 Victoria St N, Breslau, ON, N0B 1M0

-

Year established -

1978

-

NAICS -

333310 - Commercial and service industry machinery manufacturing

-

Major expansions -

-

Employees -

10

-

Exports -

United States

-

Download -

Merit Sweeprite

Located in Breslau, Merit Sweeprite manufactures street sweepers that have helped maintain roads from the Brooklyn Bridge to those in the Banff National Park. Today, its products can be found all across North America, from the Northwest Territories to Florida.

From the Brooklyn Bridge in New York City to the scenic roads in Banff National Park, street sweepers keep roadways clean and safe. Collecting cubic yards of dirt, dust, litter, and debris in each run, these vehicles prevent contaminants from entering the environment, improve air and water quality, and help prevent flooding.

While street sweepers are a common sight in cities across Canada, few know about the companies that manufacture these vehicles. Indeed, street sweeper manufacturing is a little-known, niche industry populated primarily by small companies. To excel in this competitive environment, manufacturers need to develop efficient, comfortable, easy-to-maintain, reliable, and safe vehicles while simultaneously providing impeccable customer service.

Merit Sweeprite, an Ontario-based street sweeper manufacturer that is well-recognized in its industry segment, has achieved all of that. Sweeprite vehicles have helped maintain roads from the Brooklyn Bridge to those in Banff National Park. Today, its products can be found all across North America from the Northwest Territories to Florida.

Founded in 1978 by Les Hulicsko in Regina, Saskatchewan, the company moved to Breslau, Ont. in 2018 after it was bought by Merit Manufacturing. Merit is a laser cutting, metal forming and fabricating company also based in Breslau. Sweeprite operates at a 15,000 square feet facility on the same property as Merit and employs ten people.

When Hulicsko started his company, most sweepers used sprocket and chain systems that were prone to failure and costly to maintain. Hulicsko was one of the earliest innovators in North America to replace that old technology with hydraulic systems that made street sweepers more powerful and less costly to maintain.

Sweeprite’s story begins with its founder’s. Hulicsko escaped Hungary during the 1956 Hungarian Revolution at the age of 20. He wanted to go to the United States but the immigration quota was full. In 1957, he arrived in Regina, Sask. instead, with only seventy-five dollars in his pocket. As an engineer by training and an entrepreneur at heart, Hulicsko founded his first business designing rock pickers for agricultural applications in the early 1970s. In 1978, he entered the street sweeper manufacturing industry after spotting an opportunity to disrupt the market with a new innovation: hydraulic systems. That’s how Sweeprite was born. He didn’t know at the time that the company he started would become one of the most iconic brands in the North American street sweeper industry.

When Hulicsko started his company, most sweepers used sprocket and chain systems that were prone to failure and costly to maintain. Hulicsko was one of the earliest innovators in North America to replace that old technology with hydraulic systems that made street sweepers more powerful and less costly to maintain. His dedication to design quality and high-performing street sweepers caught the attention of many. These earlier, self-propelled models designed by Hulicsko laid the foundation for Sweeprite’s reputation as a manufacturer of durable, powerful, and efficient street sweepers in the North American market.

When vehicle safety laws changed in the 1980s, the company began mounting its sweeper system onto commercial chassis compliant with new safety regulations. These vehicles became popular among urban and rural customers alike.

In 2003, after 25 years, Hulicsko sold Sweeprite to a private company and planned to retire. But the new owner’s missteps brought the company to the brink of liquidation within three years. Hulicsko bought the company back, saving it from bankruptcy. After putting the company on a more sustainable path, he sold it again in 2012, this time to a venture capital group based out of Saskatoon. The new owners started buying laser-cut parts from Merit. Despite selling the business, Hulicsko remained an influential figure at Sweeprite. In 2018, he convinced Colin Zhao, the owner of Merit, to purchase the company because he believed in Zhao’s entrepreneurial spirit. Under Zhao’s leadership, Sweeprite upgraded its vehicles and revived its old customer relationships, putting the company back on a growth trajectory.

Moreover, the company has kept all of its computer-aided designs since 1978 and can remake any original part from scratch no matter how old it is.

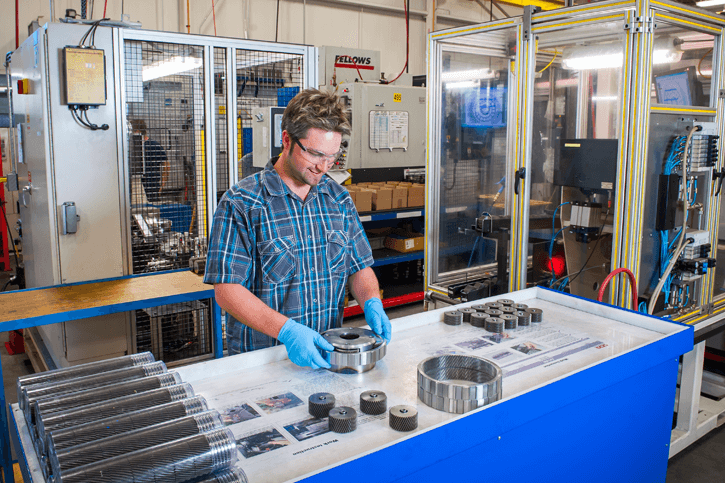

Sweeprite can manufacture 15 sweepers a year at its current production facility. To make these vehicles, the company purchases truck chassis, hydraulic cylinders, and Kubota generators. It uses off-the-shelf, non-proprietary parts so that replacements are inexpensive and readily available anywhere in North America. Components of the sweeper section including the hydraulic power systems, brooms, hoppers, wire harnesses, and conveyors are manufactured in-house. All metal assemblies are laser cut, formed and welded by Merit. R&D is also done in-house. Sweepers are tested around the Kitchener-Waterloo area before being delivered to customers.

The company believes in using an appropriate level of technology in its sweepers to ensure durability, functionality, and low maintenance costs. Lower maintenance costs give Sweeprite its most important competitive advantage against its competitors. Moreover, the company has kept all of its computer-aided designs since 1978 and can remake any original part from scratch no matter how old it is. That makes servicing older vehicles easier and allows customers to extend the lifetime of their Sweeprite vehicles significantly, increasing customer satisfaction.

In fact, when California banned the use of diesel engine sweepers built before 2005, many customers preferred to upgrade their old Sweeprite sweepers with compliant engines instead of investing in new vehicles. The company understands that maintaining long-term relationships with these customers is crucial for its success.

Sweeprite’s major customers are private contractors that do sweeping work in parking lots and construction sites. Other customers are cities and municipalities doing periodic street sweeping, construction companies doing road maintenance, and manufacturers looking to keep their facilities clean. Sweeprite’s customers value the company’s long-lasting and easy-to-maintain products. They are also extremely loyal. In fact, when California banned the use of diesel engine sweepers built before 2005, many customers preferred to upgrade their old Sweeprite sweepers with compliant engines instead of investing in new vehicles. The company understands that maintaining long-term relationships with these customers is crucial for its success.

Trade shows are the main venues for the company to meet new customers. The Federal Trade Commissioner service helps the company attend these events and provides it with new leads. The pandemic has created a significant challenge to business development efforts as many trade shows have been cancelled. The situation has not yet impacted Sweeprite as it has been working at full capacity through 2020 to fulfill its existing orders for 2021. In the meantime, the company is focusing on expanding its online presence to reach its future potential customers more easily under the current circumstances.

Sweeprite recorded positive growth a year after Merit took over. It is now considering moving to a larger facility to increase warehousing capacity by an additional 10,000 square feet. Due to the seasonal nature of the industry, Sweeprite manufactures all of its sweepers over fall and winter. Deliveries take place in spring and sales for the following year happen through the summer. Therefore, additional space is necessary during fall and winter to keep a larger inventory. The plan is to remain in Breslau to stay in close proximity to the company’s local suppliers; a key competitive advantage for the company. Proximity to suppliers substantially reduces transportation and production costs as well as turnaround times. Through the assistance of the Township of Woolwich Economic Development Office, Sweeprite has begun the process of purchasing land for this upcoming expansion.

Another challenge involves recruiting and retaining skilled tradespersons, specifically welders. The existing skilled labour shortage is one part of the problem, according to the company. The other part is the mismatch between the needs of Sweeprite and Ontario’s other critical industries. While Sweeprite needs traditional welders, colleges are increasingly shifting their focus toward training robotic welding operators needed by the automotive and metalworking industries.

Because finding new talent can be difficult, retaining existing employees is increasingly important for the company. Sweeprite’s only engineer, who has ten years of experience with the company, relocated from Regina to Breslau in 2018. That was important for Sweeprite because his knowledge of the company’s goals allows him to design products that improve the quality and performance of its sweepers without raising production or maintenance costs.

Sweeprite has endured tough conditions throughout the decades just like its founder and its sweepers. However, the legacy from Hulicsko and the new entrepreneurial energy from Zhao continues to propel Sweeprite’s growth. As a Canadian manufacturing company with a unique history, Sweeprite is an iconic brand in a niche market.

Sweeprite keeps adapting to changing market and environmental requirements: soon, you may run into a vacuum or electric version of its sweepers.

For more information about Merit Sweeprite, visit their website.

Published: April 28, 2021

Arctic Snowplows

Arctic Snowplows builds high quality front- and rear-mounted snow removal equipment for a variety of trucks and skid steer related equipment.

Ontario Drive & Gear Ltd.

Designer and manufacturer of “the world’s most capable off-road vehicle,” Ontario Drive and Gear (ODG) is the world’s leader in amphibious, all-terrain vehicles and also produces noise-reduced transmission systems.

Hybrid Power Solutions

Hybrid Power Solutions produces portable battery systems and customized energy solutions for a variety of industrial markets.