-

Headquarters -

3289 Lenworth Drive, Mississauga, Ontario, L4X 2H1

-

Year established -

2015

-

NAICS -

335990 - All other electrical equipment and component manufacturing

-

Major expansions -

N/A

-

Employees -

6

-

Exports -

US

-

Download -

Hybrid Power Solutions

Hybrid Power Solutions produces portable battery systems and customized energy solutions for a variety of industrial markets.

Established in 2015, Hybrid Power Solutions (HPS) is a company based out of Mississauga, Ontario. HPS was founded in response to the growing need for safer, cleaner, and more efficient energy solutions within industrial markets. To address this need, the company produces powerful lithium ion batteries that are compact, portable, and extremely easy to use. Lithium ion batteries have been available in consumer markets for many years, but HPS has geared their systems to respond to growing need expressed by industrial customers.

HPS’s founder, Francois Byrne, started the company out of his parents’ basement in 2015. He believed that his company would be feasible because most firms within the industrial sector were intent on switching to clean energy, and the cost of batteries was drastically decreasing. Byrne first discovered his interest in electrical engineering while building a hybrid race car for a capstone engineering project in his final year at Ottawa’s Carleton University in 2013. After graduating, he acquired experience working with batteries while employed at a railway company, where he quickly noticed the existing opportunity to provide a product that would allow transit companies to replace commercial and industrial grade generators with batteries. Since 2015, Byrne has expanded his operation into an office located in Mississauga, and hired four full-time and two part-time staff members. The successful growth of HPS has not gone unnoticed, given the company was awarded Peel Startup of the Year in 2017. Additionally, Francois received Young Entrepreneur of the Year at the Small Business Achievement Awards in 2017, and Jeune Entrepreneur, a French prize from Relève TO in 2018.

HPS specializes in designing custom battery generators. Customers who want to use clean energy can approach HPS with a description of the required capabilities of the battery generator. HPS then designs the product before outsourcing the manufacturing of components to established firms with expertise in developing the components required. These components are then delivered back to HPS, where final assembly of the product takes place. Byrne recognizes the value of utilizing the skills of other manufacturing companies within Ontario and North America to build high-quality products, which is why just over 85 per cent of HPS product components are sourced within North America. Clients that have purchased HPS custom battery solutions come from a variety of industrial markets, including mining, construction, railway, marine, and military.

HPS offers two standard products to its customer: the Batt Pack Energy and the Batt Pack Power System. The Batt Pack Energy is the safest and most reliable generator alternative on the market, with an output of 4,000 watts, 2500+ cycles, and a three-hour rapid recharge time. Although it is more expensive than a standard gas or diesel generator, customers are able to receive a return on their investment within two to three years due to fuel savings, the absence of maintenance fees, and a product life span of five to 15 years. The Batt Pack Energy does not create any fumes or pollution, which makes it safe to use in a confined indoor environment as well as outdoors.

HPS’s second standard product available for purchase, the Batt Pack Power System, is durable, waterproof, and portable, and designed to transform hydraulic, pneumatic, or gas powered tools into battery-powered systems. The Batt Pack Power system is easily customizable and can be paired with one of HPS’s high-performance motors. HPS is intent on contributing to its clients’ goal of creating a safer working environment for employees. As a result, increased safety measures in all HPS products include protection against overheating, short-circuiting, overcurrent, and overvoltage.

HPS offers customers four potential add-ons for the Batt Pack Energy: the Wi-Fi package, cold weather package, solar charging kit, and alternator charging kit. The Wi-Fi package allows customers to connect their Batt Pack Energy to an app that displays the power draw, state of the charge, number of cycles, faults and errors, and other data that can be used to maximize efficiency. The cold weather package provides an internal heating system that warms the battery during charging to increase power and energy output, and prevents damage to the battery. The solar charging kit and alternator charging kit provide the customer with alternate charging options.

The majority of the company’s customers are mining and transit companies within Ontario and Quebec, since firms within these two industries are expending huge costs by ensuring they meet Tier 4 diesel engine regulations, as well as employee safety regulations. Customers value HPS products because they eliminate the issue of unsafe or unhealthy working environments, and offer a lower product lifetime cost. Customers also appreciate how easy the products are for end users to operate; all that is required is the simple flick of an on/off switch, and charging can be done from a standard wall outlet.

HPS continues to attract new customers through the use of four small distributor companies. Byrne chose small distributor companies so that one sales employee would be dedicated solely to marketing and selling HPS products. Moreover, he finds it much easier to educate distributors about a new and innovative product when their focus is on one company only. In addition, Byrne undertakes networking and cold-calling to notify potential clients about the beneficial energy solutions that HPS provides. As a result of his efforts, HPS is slowly establishing a presence in Western Canada and plans to hire distributors there as well. Byrne has also begun establishing a presence in the U.S. with companies in Boston and Long Island. Additionally, the New York City Transit Authority has purchased demo units from HPS to cycle around their departments and gather mass purchase orders.

Byrne has been successful in utilizing government programs to assist with the growth of HPS. First, for the past year, he has been involved with the National Research Council’s Industrial Research Assistance Program (IRAP). IRAP provides various funds, access to networks, and an experienced advisor to help navigate challenges associated with starting a new business. Second, Hybrid engages in substantial research and development (R&D) at Mohawk College through its involvement with the Southern Ontario Network for Advanced Manufacturing Innovation (SONAMI). Third, Byrne has capitalized on benefits from the Trade Accelerator Program (TAP) offered by Mentor Works, a program that helps companies develop export strategies. Although Byrne acknowledges that some government programs have been quite difficult to navigate, he has appreciated their assistance in overcoming initial funding challenges.

Entering new markets and arranging interviews with large industrial companies is a major challenge that Byrne is preparing to undertake. It can be extremely difficult for small firms to get the opportunity to present their products to large companies like the New York City Transit Authority. However, Byrne uses the awards that HPS has won as a marketing tool to demonstrate the innovation and quality that his company provides. Securing larger customers means that HPS will have to complete the integration of its supply chain to ensure the manufacturing process is smooth when larger component orders begin. Byrne is currently working to complete this integration with high-quality suppliers. In the long term, he plans to bring production of all components in-house, but will only do so when his company is able to produce components of the same quality as the current components. In the short term, HPS is looking to manufacture products with even larger power capabilities.

The most significant threat facing HPS is the possibility of larger competitors taking the firm’s innovative idea and mass-producing similar products. Byrne is well aware of this possibility, and understands the importance of expanding as quickly as possible to develop loyal customer relationships with large companies immediately. Much of the company’s R&D is done with the intention of cementing the company as an industry leader, so that when direct competitors begin to enter the market, HPS will already have ideas and designs for new products. Byrne is diligent about collecting customer feedback on existing products so he can use this feedback to design and manufacture new products.

Byrne hopes to relocate to a larger facility in the near future as well. Current employees include a technical production manager, a power engineer, a sales representative, and a part-time marketing student. HPS also uses a temp agency, Indeed, to hire additional employees when products must be assembled, since the lack of integration within the supply chain results in the flow of components fluctuating drastically when being delivered. Byrne wants to hire more technical employees and engineers moving forward, which is why he plans to relocate to a region where the appropriate talent is available; this will help alleviate the challenge of finding the talent he requires to continue the growth and success of his company.

HPS began generating revenue in 2017, and has experienced exceptional growth in 2018 up to this point. Based on the firm’s current growth, Byrne believes he will be able to double sales—and the number of full-time employees—every year for the next five years. With its strong focus on the custom battery market, Hybrid Power Solutions is well-equipped to continue providing clean energy solutions to a wide range of innovative companies.

For more information about Hybrid Power Solutions, visit their website.

Published: October 11, 2018

Trojan Technologies

Trojan Technologies is engaged in the design, manufacturing and sale of ultraviolet disinfection systems for municipal wastewater, drinking water systems for residential, municipal and commercial use, and industrial systems for food and beverage, pharmaceutical, and semiconductor applications.

DAVWIRE: Defense & Aviation Wiring

Defense & Aviation Wiring Inc. (Davwire) is one of Canada’s leading contract manufacturers in the electrical/electronic arena. The company specializes in wire harnesses, electrical panels and electrical assemblies used in aviation, defence, medical and rail industries.

Electronic Craftsmen

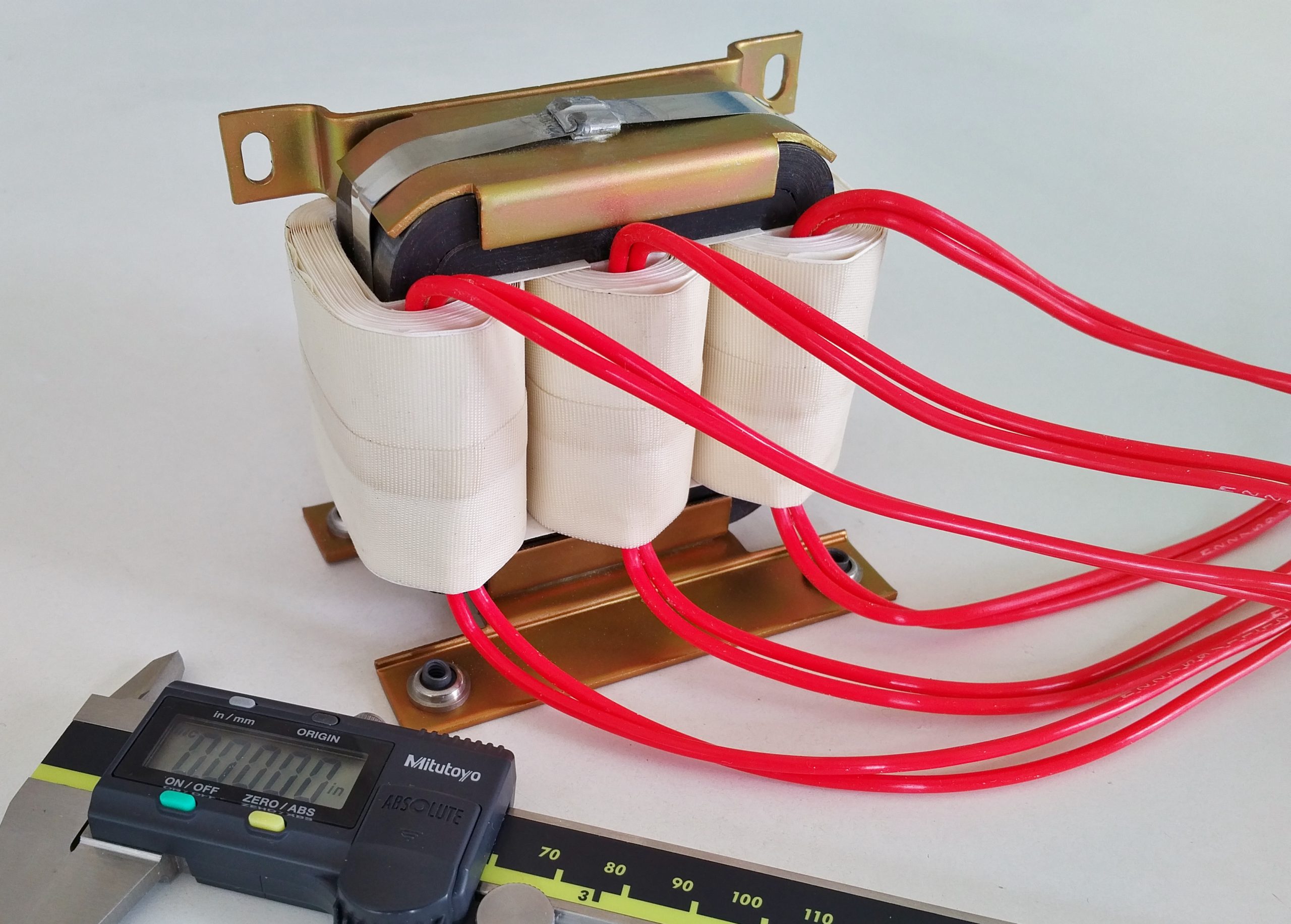

Electronic Craftsmen is a custom designer and manufacturer of specialty transformers, inductors, chokes, and reactors for use in power electronics applications.

J&S Manufacturing

J&S Manufacturing is a mining equipment manufacturer, with in-house design capabilities that allow the firm to manufacture mobile equipment as well as technical custom equipment. The company’s motto is “Built to Perform”.

WEGU Manufacturing Inc.

WEGU Inc. is a multi-international manufacturer of molded rubber and plastic products. Product design assistance, engineering, tooling development, prototyping, testing and manufacturing, and materials analysis, are all offered in house. WEGU Inc. prides itself on the ability to consistently meet all of their client’s physical and chemical requirements for product durability, flexibility, noise and vibration mitigation, and abrasion resistance.