-

Headquarters -

1 Quebec Drive, Seguin, Ontario, P2A 0B2

-

Year established -

1977

-

NAICS -

332999 - All other miscellaneous fabricated metal product manufacturing

-

Major expansions -

1988

-

Employees -

70

-

Exports -

US

-

Download -

Kropf Industrial

Kropf Industrial Inc. manufactures CONOLIFT marine hydraulic equipment, dock systems, and other equipment for the industrial and aquaculture sectors.

Organization

The town of Parry Sound, Ontario and the surrounding Muskoka region is one of the most famous boating areas in Canada, if not the world. Therefore, it seems fitting that it is also home to a leading marine hydraulic equipment and dock systems manufacturer, Kropf Industrial Inc. Kropf Industrial is a family-owned and -operated company that is run out of two facilities just south of Parry Sound, comprising a total of 40,000 square feet.

History

Kropf Industrial began in 1977, when long-time local resident Peter Kropf started a mobile welding shop out of the back of his pickup truck. In the early 1980s, he was approached by a friend to build a hydraulic boat trailer. Peter agreed to take on the project and the first Kropf Conolift marine hydraulic trailer was produced.

After seeing the success of his first trailer, Peter realized he was on to something and began specializing in trailer manufacturing. The business was eventually incorporated in 1985, becoming Kropf Industrial. In 1988, Peter decided to diversify the company by purchasing the assets of a steel tube dock manufacturer that was going out of business. This was in response to request from existing clientele to supply them with steel docks. The floating dock division began to experience steady growth with both commercial and residential clients.

Today, Conolift marine hydraulic trailers and floating docks remain the two main branches of the business. However, Kropf Industrial also uses the experience gained over the years in these two areas to produce other products for the aquaculture and industrial markets. Peter has since retired—although he does pop in from time to time when he is needed—and today the business is run by his children, Darin, Jordan, and Kara, as well as his brother-in-law Derrick Gingrich and nephew Tim Gingrich.

Performance

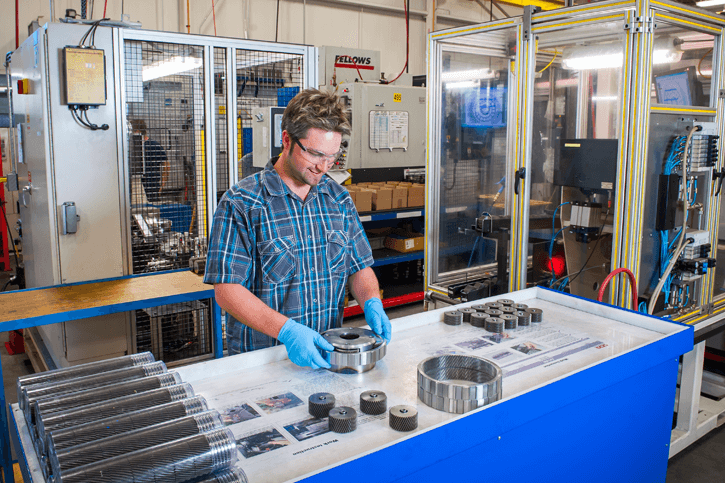

One of the factors that helped make Kropf Industrial so successful is its ability to customize. This ability stems primarily from its vast machining capabilities and qualified workforce. Not only does the company’s shop contain the various technologies required for large-item manufacturing (e.g., welding equipment, crane service, etc.), but it also has CNC machining capabilities so that it can produce its own small parts. This feature allows Kropf Industrial to cater to specific customer needs by designing and manufacturing individualized parts that go into the larger items like trailers or dock systems.

Further, Kropf Industrial can accommodate customers’ unique demands because it has a diverse workforce of apprentices, welders, fabricators, and other individuals trained in skilled trades. By employing a wide array of skilled workers, Kropf Industrial is able to boast expertise in all aspects of the production process. Even more beneficial is the fact that most of these employees can be taught everything they need to know after they arrive at the company because experienced employees are eager to pass on their knowledge.

Another way Kropf Industrial maintains its competitive edge is by staying on top of market trends in the marine industry. While 95 percent of its sales are business-to-business sales (to marinas, yacht clubs, municipalities, boatyards, etc.), its customers service the recreational boating industry so Kropf Industrial aims to stay familiar with the trends and changes in this market; the company does this by maintaining strong relationships with its customers and serving as a member of industry organizations like Boating Ontario, the National Marine Manufacturers Association Canada, and the Association of Marina Industries.

By staying abreast of trends and producing the most cutting-edge trailers and dock systems, Kropf Industrial has been able to secure business both domestically and internationally—though surprisingly little of its revenue comes from the local area. About half of the company’s revenue from the trailer side of the business comes from the United States (meaning that exports comprise one-quarter of total revenue), while on the dock side, Kropf Industrial focuses on larger projects for stakeholders like the cities of Hamilton and Orillia.

Kropf Industrial has been recognized as a successful and growing Ontario manufacturer by many organizations and levels of government. In particular, the Northern Ontario Heritage Fund helped the company expand its facility in 2016 by providing funding for a new building. This building houses Kropf Industrial’s state-of-the-art sandblasting and painting equipment, and has enabled the firm to continue responding to its customers’ demands for quality and customization.

Challenges

One of the challenges that Kropf Industrial has faced since its inception is managing its constant growth. The transition from a small shop employing a few people to a large facility now employing 70 workers was far from seamless; however, it is one that the ownership team embraced and ultimately survived by recognizing the need to expand when necessary in order to harness opportunities for growth.

The company’s management know that future challenges will include adapting to changing equipment in the industry. For example, many marine products now incorporate radio remote controls and other advanced materials and systems. Kropf Industrial must continue to anticipate these shifts in the market and utilize its qualified team and technology to maintain its reputation as one of the top suppliers in the industry.

Prospects

Kropf Industrial is focused on expanding into two areas in the near future. First, it hopes to improve its after-sales service to offer an even better customer experience (e.g., by producing improved owner’s manuals for all of its equipment). Second, the company plans to increase its presence in industrial industries. Kropf Industrial has years of experience producing quality equipment for the marine industry, and many of its customers have noted that the firm could utilize its technology in other sectors, such as mining, oil and gas, and heavy manufacturing (bridges, structural steel, etc.). Essentially, these industries require skill sets and technological capabilities that Kropf Industrial already possesses, so management is looking to leverage these assets. At present, industrial markets account for roughly 5-10 percent of the company’s sales but this number could certainly increase in the years to come.

At its core, Kropf Industrial will continue to remain a family-run business committed to meeting its customers’ demands for customization and top-quality products, as well as a significant player in Northern Ontario’s advanced manufacturing industry.

For more information about Kropf Industrial, visit their website.

Published: October 22, 2018

Shimco

Located in Cambridge, ON, Shimco has served the aerospace, defense, space, industrial and other industries worldwide with precision manufactured parts, laminated and edgebond shims, tapers and spacers for over 25 years. Shimco offers a tradition of Innovation, Precision, and Execution, providing solutions that conform to exacting international and customer-specific standards.

Industrial Parts Manufacturing

Industrial Parts Manufacturing specializes in CNC machining, general machining, welding and fabricating.

Parmerit Inc. | Wolfe Heavy Equipment

When selecting a product or service, manufacturing customers look for companies that can deliver high quality and expertise. Parmerit Inc. (Parmerit) and Wolfe Heavy Equipment (Wolfe), two manufacturing companies located in Strathroy, Ontario, are companies that clearly understand the needs of their customers. Not only do they offer technical expertise, they also have an ability to manage projects and products tailored to their customers’ specific needs.

Ontario Drive & Gear Ltd.

Designer and manufacturer of “the world’s most capable off-road vehicle,” Ontario Drive and Gear (ODG) is the world’s leader in amphibious, all-terrain vehicles and also produces noise-reduced transmission systems.

Timberland Equipment

Timberland Equipment is a global leader in the integrated design, manufacture and support of engineered winches, hoists, sheaves, derricks and tensioning equipment for the world’s most challenging infrastructure and capital equipment projects.