-

Headquarters -

6800 Montrose Road, Niagara Falls, Ontario L3E 6V5

-

Year established -

1964

-

NAICS -

333416 - Heating equipment and commercial refrigeration equipment manufacturing

-

Major expansions -

1965

-

Employees -

120

-

Exports -

US, Chile, Mexico, China, Russia, India

-

Download -

Can-Eng Furnaces International

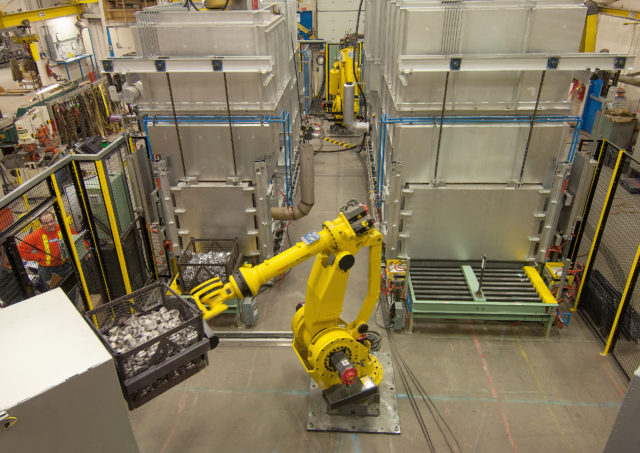

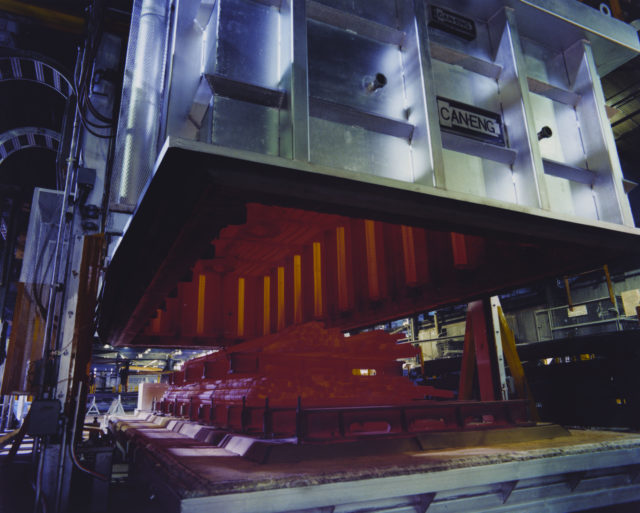

Can-Eng Furnaces International is one of North America’s leading designers and manufacturers of thermal processing equipment for ferrous and non-ferrous metals.

Can-Eng Furnaces International Ltd. (Can-Eng) custom engineers heat-treating equipment in a busy manufacturing facility located several blocks from the famous Niagara Falls. Established in 1964, Can-Eng has grown to become a leading designer and manufacturer of thermal processing equipment for ferrous and non-ferrous metals.

In 1964, Can-Eng started with an order from a U.S. furnace manufacturer, for design engineering. Within a month, an order was obtained for a $100,000 furnace line for Thompson Products (TRW) in St. Catharines, ON, a major contract 50 years ago. “The heavy industrial manufacturing base in Hamilton and Niagara were very key to us in the 60s, and 70s” said Michael Klauck, President of Can-Eng.

Michael Klauck, is a graduate of the metallurgical engineering program at McMaster University in Hamilton, ON. He has spent nearly 30 years in all aspects of iron and steel production, from primary steelmaking to the finishing floor. Prior to joining Can-Eng, Klauck held positions at Atlas Specialty Steels in the Metallurgical Technology Group, and was a Division Manager at the vacuum heat treatment operations of Bohler Uddeholm, the world’s largest producer of specialty steels.

Can-Eng built its original manufacturing site in Niagara Falls because, at the time, the city was in close proximity to major customers, including General Motors and TRW in St. Catharines, Atlas Steels in Welland, DOFASCO – Hamilton and International Nickel in Port Colborne. In 1965 the company established a wholly-owned subsidiary in Mexico (SELMEC) and had major contracts for six complete hardening and tempering lines for automotive leaf springs in Chatham, ON, an amazing accomplishment for a fledgling corporation.

Klauck worries that the customer base in Ontario has been seriously eroded in the past 10 years. “Once you lose momentum, it is very hard to get back on track.” He argues. This is true for Canada, and more so for Ontario manufacturing which is still the economic engine of the country. Klauck believes that for a company to be successful on the global stage they must compete on technology and be prepared to take the risks necessary to become an innovation leader.

In the 1980s, Can-Eng received major equipment orders from leading Ontario manufacturing plants such as GM Transmission in Windsor; International Harvester in Hamilton; Garland Commercial Ranges in Mississauga, and Hyundai Automotive Newmarket . While Can-Eng still receives 15 percent of its new equipment contracts from the Canadian market, its primary market is now in the United States, which represents 70 percent of company revenue.

Can-Eng’s international customers stretch to Chile, Mexico, Russia, China and India. Klauck travels extensively on business. Can-Eng is highly involved in a variety of shows and exhibitions all over the world, as it is an effective way to develop contacts and build a network internationally. Klauck goes to Russia, China and India to do business in person, and has developed contacts in many markets.

Annual sales revenues were about $15-20 million when Klauck joined Can-Eng 15 years ago; rising to $60 million today. The company took calculated risks to achieve its growth. “We are designing and developing industrial furnace systems and automation that did not exist 15 years ago, in this sense we are creating our own vision of the future. When we see a customer need for an innovative solution, we engineer, prototype test, and continue to evolve our designs based on key lessons learned.”

Can-Eng has gained an international reputation for innovative design and quality workmanship. In the 50,000 square foot Niagara Falls site, Can-Eng has its own R&D facility— the Technology Development Centre; it utilizes existing engineering tools such as 3D modeling and computational fluid dynamic modeling to support the ongoing research and development. To accommodate the peaks and valleys in the order book, Can-Eng has another 40,000 square foot high bay facility in Welland, 10 kilometers from the company headquarters.

Klauck feels strongly that IP in equipment is not solely what Can-Eng is about. It’s about people—the company’s most valuable asset. There are 120 employees in total, 70 of them in engineering and sales. Most of the employees are local and finished their education in McMaster University, University of Toronto, University of Waterloo, Niagara College and Mohawk College.

According to Klauck “we have no problem attracting mechanical engineering people, but electrical and automation engineers are harder to attract, because their skills sets run across many industries.” That’s why Can-Eng decided to open a new automation design office in Burlington, ON. The main purpose is to attract the skill sets that are more readily available in the Burlington to Toronto engineering corridor. “If talented people are not coming to us, we are better to move closer to them,” said Klauck.

Klauck holds up Germany as a model for leveraging partnerships between governments, the private sector and educational institutions, and he feels strongly that Ontario needs to improve greatly in this area to be able to attract and grow companies here. He believes that to attract more business to Ontario, governments need to develop a comprehensive strategy that consider a spectrum of factors: incentives for research and development; energy costs; taxation; appropriate training and development of skills sets; and better coordination of effort by the three levels of government. Governments need to help show prospective investors that Ontario is the best place to do business in the world.

Can-Eng has succeeded through innovation, development of intense industry knowledge and relationships, and the attraction of an intelligent and dedicated workforce. However, as it strives to grow ever larger it must consider where the next stages of growth will be based—here or somewhere outside of Canada. Klauck feels strongly that a comprehensive strategy and more effective education partnerships are critical to ensuring that growth continues in Ontario.

For more information about Can-Eng Furnaces International, visit their website.

Published: January 26, 2016

Direct Coil

Direct Coil manufactures commercial and industrial finned tube heat exchangers, as well as custom engineered refrigeration and heat transfer equipment.

Heat Design Equipment

Heat Design Equipment manufactures infrared heaters for asphalt construction and repair using patented, state of the art technologies.

Structural Panels

Structural Panels is a manufacturer of high-quality, steel-skinned, insulated sandwich panels that are ideal for walls, partitions and ceilings.

Samco Machinery

Samco Machinery is a global innovator in producing roll forming machinery and custom built material handling solutions. In business for over 45 years and maintaining ISO 9001 certification, our services include: consultation, engineering, installation, training, commissioning, ongoing maintenance, support, and parts.