-

Headquarters -

8 Tilbury Court, Brampton, Ontario, Canada, L6T 3T4

-

Year established -

2001

-

NAICS -

333248 - All other industrial machinery manufacturing

-

Major expansions -

2007

-

Employees -

90

-

Exports -

US, Chine, South America

-

Download -

AFA Systems

Packaging machinery manufacturer AFA Systems stands out from other manufacturers because in its case, the end of the assembly line is just the beginning.

AFA ensures that the final step, packaging, is integrated into the production process and products are ready for shipment. For the company’s food, beverage, and pharmaceutical manufacturing customers, the automation of this critical step saves time and money, making its offerings key to getting products to market.

Founded by Paul Langen in 2001, and currently owned by brothers Paul and Jack Langen, AFA Systems Inc. provides customized, automated packaging systems that include robotics, case packers, palletizers, and case erectors. The company is located in Brampton, where it employs 90 people whose technical skills help the company focus on the unique requirements of each customer.

The company has its roots in Langen Packaging, founded by Paul Langen’s father in 1956 in Etobicoke, Ontario. In 1996, Paul Langen sold Langen Packaging to Molins PLC, a publicly-traded company based in Britain. Paul remained with the company, operating as Molins Langen Packaging, until 2000. He left to develop microwave popcorn packaging and eventually acquired AFA Systems, an industrial automation company.

About 20 per cent of the company’s sales are in Canada, 50 per cent in the United States, and 30 per cent spread across South America, Europe and Asia

In 2002, AFA acquired Nordale Packaging and its end-of-line carton making and case packing capability, making AFA a full-service packaging automation company offering products and services. The company continued to expand, and it moved to its current location in Brampton in 2007, with a second office located in Shanghai, China.

Proximity to Pearson International Airport and the well developed GTA supply chain allows AFA to export 80 per cent of its products outside of Canada. About 20 per cent of the company’s sales are in Canada, 50 per cent in the United States, and 30 per cent spread across South America, Europe and Asia. Large consumer products companies including Kellogg’s, General Mills, Kimberley-Clark and Clorox are among the Fortune 1000 companies making up 80 per cent of AFA’s customers. The remaining 20 per cent are smaller manufacturers looking for engineer-to-order builds.

The current workforce is comprised of a diverse group of tenured employees who have developed their skills through many years of experience... Replacing tenured workers nearing retirement requires a focused investment by the company

The business depends on well developed logistics systems to ensure that complex equipment is not damaged during shipment. In addition to the supply chain benefits, AFA’s move to Brampton in 2007 brought it closer to the talent it hopes to attract. The area is home to other advanced manufacturing companies including a competitor in the packaging industry. AFA hopes that its customer-focused, family-owned culture will attract skilled tradespeople. The current workforce is comprised of a diverse group of tenured employees who have developed their skills through many years of experience. About 90 per cent of employees were born outside of Canada. Many of them previously worked at AFA Systems’ competitor companies and brought relevant experience to the company.

Replacing tenured workers nearing retirement requires a focused investment by the company. Nearly half of the employees are electrical and mechanical engineers. Their experience takes years to replace, even with well-qualified engineering and trades program graduates. A co-op program invites engineers from many different GTA colleges and universities including Sheridan College and the University of Waterloo to gain exposure to the company and its culture, and AFA hopes to retain high-potential students on a full-time basis upon graduation. Convincing engineering students to choose machining over software is an ongoing challenge for AFA and its advanced manufacturing peer companies.

AFA’s value proposition is its ability to develop custom solutions for its customers. The primary focus on the sales staff is to attend international trade shows, spending time with local customers, agents and distributors. As the traditional food, beverage and pharmaceutical customer base continues to grow, their automation needs grow with them. Each response to requests for proposals offers an innovative solution that addresses the unique needs of the customer. The company continues to introduce new product lines that improve operating efficiency by robotically feeding, packing, sealing and palletizing products.

AFA invested in the research and development required to build the solution. Clearwater Seafoods now runs this product on two lines, with packaging that has resulted in major savings in shipping costs for the company

A focus on design has benefitted AFA’s Canadian and global customers. When Clearwater Seafoods in Newfoundland wanted to reduce shipping costs by fitting bags of surf clams into smaller boxes, it looked to North American and European suppliers, none of which could meet this need. AFA invested in the research and development required to build the solution. Clearwater Seafoods now runs this product on two lines, with packaging that has resulted in major savings in shipping costs for the company.

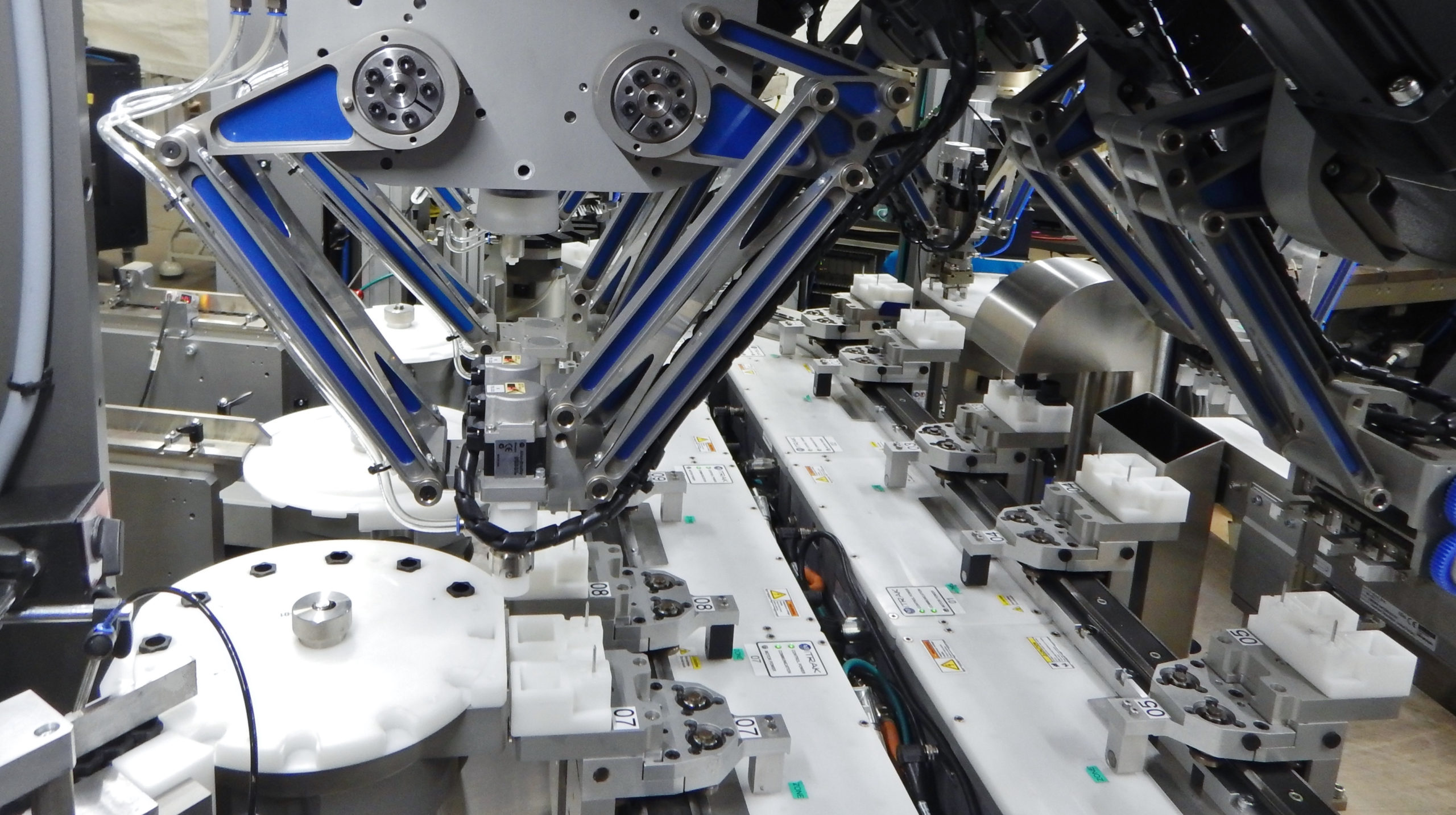

A global example of a customer-driven solution comes from a Chinese manufacturer of health tonics looking for a way to package liquids in 100ml bottles, 50 to a carton that could convert to a tray once opened. AFA designed a new machine assembly. Six AFA Systems robots are part of a complex system that accomplishes all of the customer’s requirements within a 30 square foot area, about half the space typically needed for a multi-machine solution.

One of the services AFA offers is training of customers’ machine operators and technicians. The Association of Professional Engineers of Ontario authorized the company to offer professional engineering services

On the services side, AFA technicians help customers improve their performance by integrating, rebuilding and retrofitting existing equipment. One of the services AFA offers is training of customers’ machine operators and technicians. The Association of Professional Engineers of Ontario authorized the company to offer professional engineering services. The customer training program is certified by the Packaging Machinery Manufacturers Institute, a U.S.-based organization that connects packaging suppliers with manufacturers of goods.

AFA competes with other large-scale global automation companies, primarily from the United States, Germany and Italy. China is emerging as a supplier of lower-priced machines that are more difficult to integrate into existing automated processes. Again, customization is AFA’s differentiator. The industry has focused on developing standard equipment and encouraging the customer to adjust its processes to suit the machine. AFA prefers to look at the customer’s existing processes and engineer a solution that will fit the business requirement. The company has incorporated the use of digital twins to virtually replicate how solutions align with customer’s unique requirements.

Two emerging business opportunities for AFA stem from the changing needs brought about by the global pandemic. Producers of personal protective equipment are looking for automated packaging solutions to help meet the vast demand for products; AFA is well-positioned to help. AFA also hopes to expand its footprint in large warehouses, predicting that packaging automation could replace up to 40 operators in major distribution centres such as those scattered throughout the Brampton area.

No matter where the future takes the company, AFA is proud of its diversity, its family-owned culture, and the role it plays in automating the end of the production line, knowing that the end of the line represents a starting point for a company getting products into the market.

For more information about AFA Systems, visit www.afasystemsinc.com.

Published: June 2, 2021

Dasco Storage Solutions

Headquartered in Brampton, Ontario, Dasco Storage Solutions designs and manufactures secure and durable storage products for customers across a range of industries in which security is of the utmost importance.

Linear Transfer Automation

Based in Barrie, Ontario, Linear Transfer Automation is a global supplier of press transfer automation, blank feed systems, and press-to-press automation. Linear is able to customize its automation solutions to fit specific equipment geometry and requirements for customers.

Proto3000

Based in Vaughan, Proto3000’s design, additive manufacturing, and metrology technologies help customers solve complex engineering and manufacturing challenges, resulting in shorter cycle times, more flexible supply chains, faster prototyping and more efficient production.

Transformix Engineering

Transformix Engineering is exclusively focused on CNCAssembly® technology in the specialized niche of "continuous motion", and have developed it into a general solution for small-part assembly.

Parmerit Inc. | Wolfe Heavy Equipment

When selecting a product or service, manufacturing customers look for companies that can deliver high quality and expertise. Parmerit Inc. (Parmerit) and Wolfe Heavy Equipment (Wolfe), two manufacturing companies located in Strathroy, Ontario, are companies that clearly understand the needs of their customers. Not only do they offer technical expertise, they also have an ability to manage projects and products tailored to their customers’ specific needs.