-

Headquarters -

1150 Gardiners Road, Kingston, Ontario, K7P 1R7

-

Year established -

1995

-

NAICS -

333990 - All other general-purpose machinery manufacturing

-

Major expansions -

2009

-

Employees -

53

-

Exports -

EU, US, South America

-

Download -

Transformix Engineering

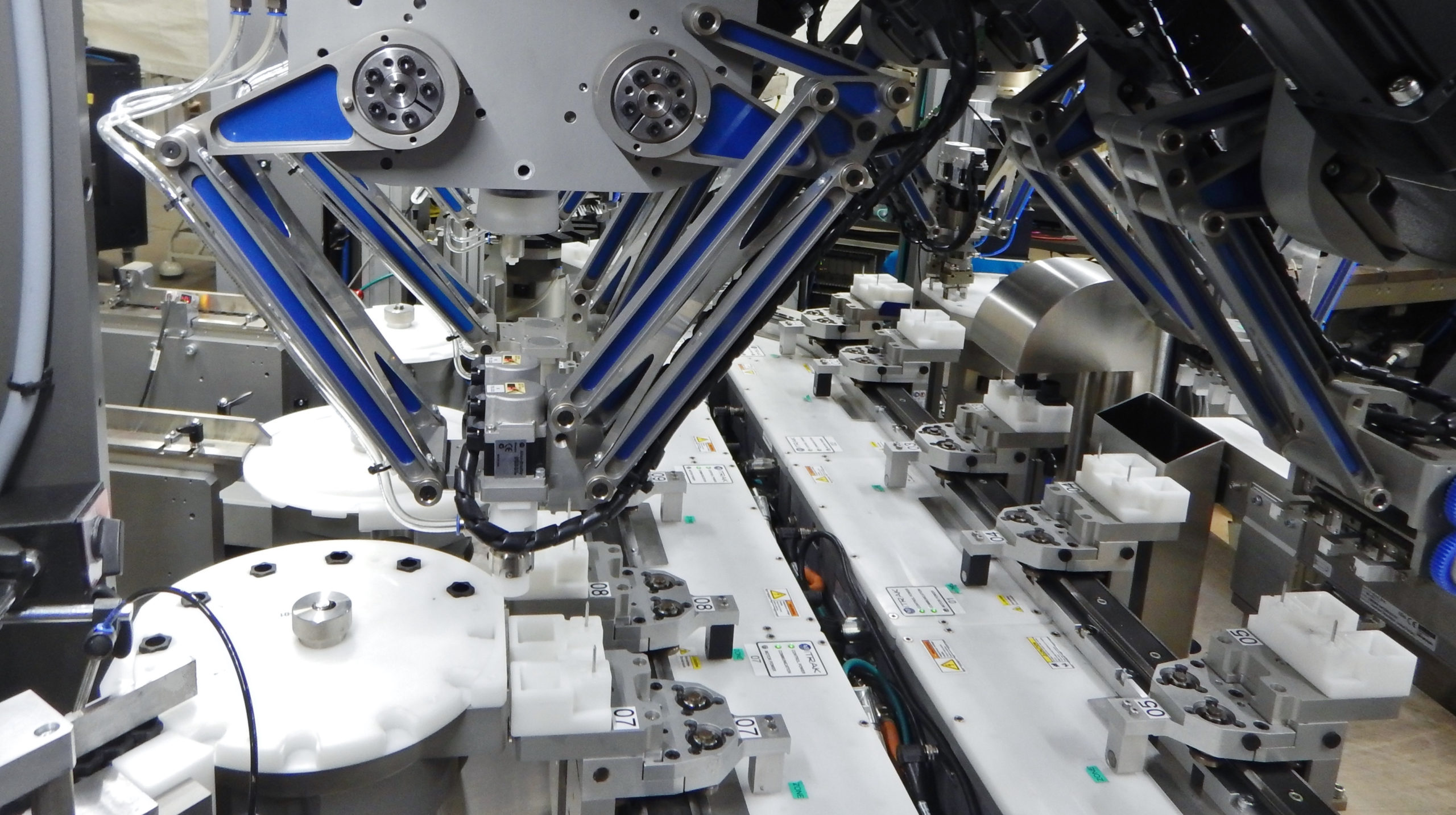

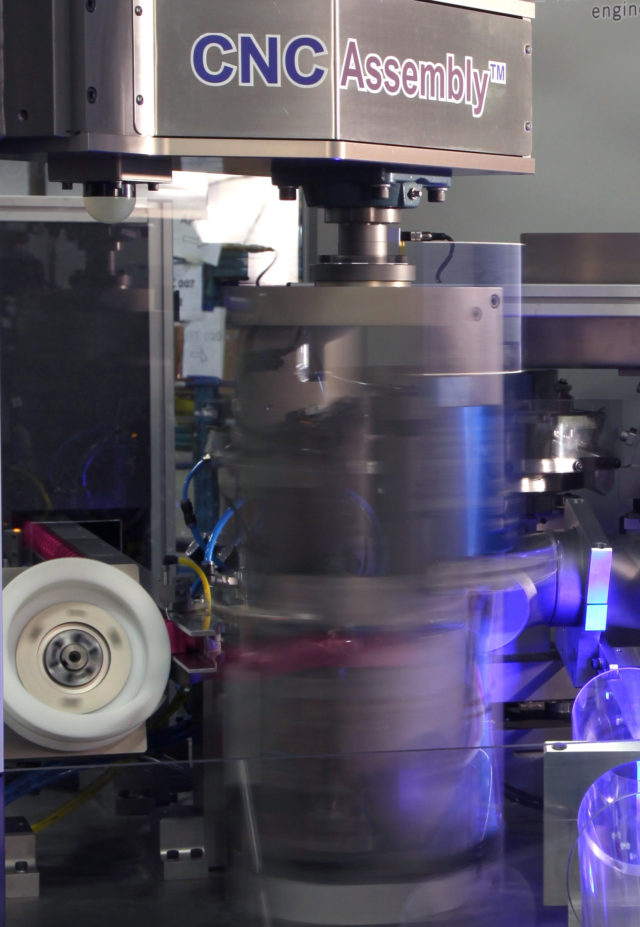

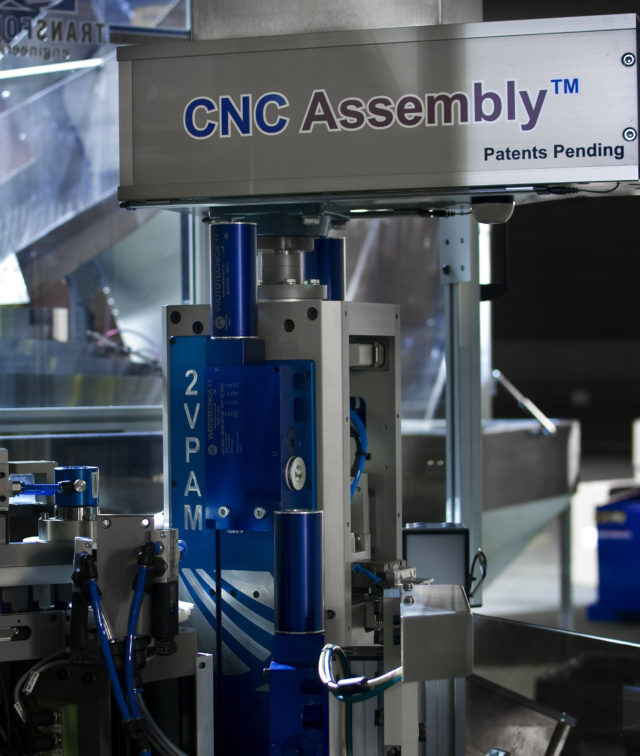

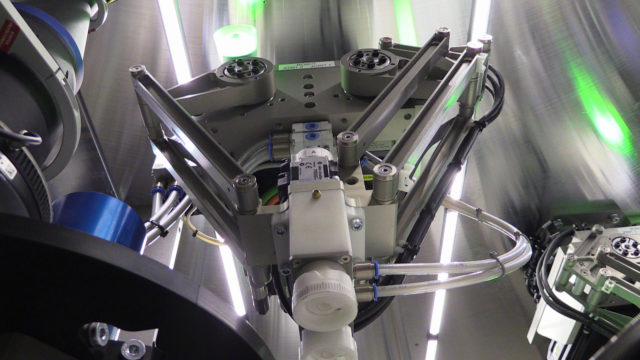

Transformix Engineering is exclusively focused on CNCAssembly® technology in the specialized niche of "continuous motion", and have developed it into a general solution for small-part assembly.

There are a multitude of success stories that demonstrate not only the innovative technologies and entrepreneurial spirit that drive Canadian manufacturing, but also the positive contributions that so many immigrants make to our economy and society. As Canadians, we are privileged to enjoy a standard of living that far exceeds global norms; the struggles that many refugees and immigrants face are often unimaginable to most of us. Yet adversity can act as a powerful motivator, driving one’s ambition for a better life; this is certainly the case for Peng Sang Cau, president and chief executive officer of Transformix Engineering (Transformix).

Cau was born in Cambodia during the country’s darkest period, the reign of the Khmer Rouge, during which her family lost a child to the horrors of the ‘killing fields’. After Vietnam invaded the country in 1978, the surviving family members gained refugee status and were eventually able to immigrate to Canada, albeit with only the clothes on their backs.

During the years that followed, education and hard work were the focus of the family’s new life in Saskatchewan. This dedication paid off for Cau when she graduated with a degree in commerce from Queen’s University. However, her propensity for hard work would continue to guide Cau, and in 1995, she and three engineering graduates founded Transformix, initially operating out of her basement.

Originating as an engineering consulting firm and later adding custom machine shop services, Transformix has evolved steadily, broadening its market horizons from regional to global, and taking its ambitions and products to the global forefront of advanced manufacturing. The firm’s current efforts are focused on its patented and trademarked “CNCAssembly®” technology and products, creating highly standardized and flexible assembly machinery that can be configured to assemble a vast array of potential products with incredible speed and accuracy.

Initially, when approached by businesses looking to automate repetitive assembly processes, Transformix would need to design an end-to-end assembly process according to each customer’s specific application and requirements. However, a major multi-year contract with a European agrochemical firm put Transformix on a new path starting in 2009. The specific business application involved automating the processing of sugar cane for seed removal and planting, in Brazil. The research and development (R&D) and innovation spurred by this particular contract led to the development of new system products that have been granted patent protection (initially in Canada and Singapore, and with additional patent approvals pending).

This novel CNCAssembly® technology works from a set of standardized proprietary, programmable robotic “engines” that are physically linked and supported by customized software according to each customer’s assembly requirements. The ability to configure a customized solution for a wide range of customer needs through utilizing a set of standard yet flexible “engines” has lead to significant efficiencies, and streamlining of operations for Transformix.

Perhaps more importantly, the efficiencies and cost reductions from this approach are a major advantage to the customer. Tooling requirements are reduced by 80 to 90 per cent with these systems, saving both time and money. With the implementation of CNCAssembly®, manufacturers are also able to condense a conventional assembly process into a much smaller area. This eliminates wasted time in moving parts from one process (machine) to the next, and optimizes assembly footprints, while realizing extremely high assembly speeds and quality.

Finally, the inherent flexibility of the CNCAssembly® technology also offers gains that go beyond operational savings since it enables customers to take new products to market more quickly.

As Cau explains, “If you do not have the latest mouse trap, the executives of large multi-national companies won’t bother talking to you.”

Yet Transformix’s new technology not only enjoys validation from international patenting authorities but is also attracting attention from far-flung customers: the company currently exports 100 per cent of its product (50 per cent to Europe, 45 per cent to the United States, and 5 per cent to South America). Cau emphasizes the need for Canadian manufacturers to make the type of investments in machinery and systems that their global customers are already undertaking to stay technologically innovative and cost-competitive. In the case of Transformix, R&D has also been critical to its success to date. Cau points to the federal government’s SR&ED Tax Incentive as one of the best programs for firms like hers, although she also notes that certain changes to the program over time “have been detrimental.”

Transformix currently has a total of 53 employees, 23 of whom are engineers, which aligns with the highly innovative nature of the business. The company’s Kingston, Ontario location means that the majority of its engineers are graduates of Queen’s University, like the original founders. However, having an engineering degree is not enough to guarantee a position at Transformix. The company looks for individuals who can think “outside the box,” while working on a fixed timeline and budget. They must also exhibit the four pillars of success established by the founders of Transformix: Integrity, Innovation, Respect and Passion. Or as Peng likes to say: “ Success = I^2RP”. One of the ways that Transformix identifies future full-time employees is through various co-op programs and summer student positions. If new “temps” do well within the company, they tend to be hired for permanent positions.

There are many ways in which innovation is fundamentally changing conventional practices across a broad range of industries, and that includes all aspects of manufacturing. True to its company name, Transformix is transforming the applicability of automated assembly: a testament to its founders’ skillfulness and perseverance.

For more information about Transformix Engineering, visit their website.

Published: October 12, 2016

Givens Engineering

Givens Engineering Inc. designs and manufactures light cranes, manipulators and machinery for industrial use. The company specializes in lifting equipment and automated material-handling machines.

Angstrom Engineering

Angstrom Engineering Inc. is a leading manufacturer of thin film vacuum deposition equipment and vacuum chambers equipment. The firm specializes in designing, manufacturing, selling and servicing machines that deposit thin films, (growing layers of materials on a substrate with thicknesses that can range from less than one nanometer to several microns).

Abuma Manufacturing Limited

Abuma Manufacturing Ltd (Abuma) is a Build-to-Print metal fabricator capable of manufacturing custom components. Abuma fabricates the metal components and upper-level assemblies and integrates additional outside services like surface coatings, electrical, pneumatics, and purchased equipment as required.

Linear Transfer Automation

Based in Barrie, Ontario, Linear Transfer Automation is a global supplier of press transfer automation, blank feed systems, and press-to-press automation. Linear is able to customize its automation solutions to fit specific equipment geometry and requirements for customers.

BOS Innovations

BOS Innovations develops custom factory automation solutions to help companies reach greater levels of productivity and profitability. The company’s mission is to advance North American manufacturing through world class integration of automation systems with innovative engineering, build quality, and service.