-

Headquarters -

3015 North Talbot Road, Oldcastle, Ontario, N0R 1L0

-

Year established -

1996

-

NAICS -

332210 - Cutlery and hand tool manufacturing

-

Major expansions -

2014, 2016

-

Employees -

235

-

Exports -

US, Mexico, EU

-

Download -

Select Tool Inc.

Select Tool is a manufacturer that has developed a reputation for providing high quality full-service gauges, fixtures, automation, and specialty tooling for the automotive, aerospace, and transportation industries.

Select Tool Inc. is a full-service supplier to original equipment manufacturers (OEMs) and tier 1 and tier 2 suppliers. Based out of Windsor, Ontario, this privately owned company began as a fixture and sub-contract machine shop in 1996. As growth continued the company became one of the largest suppliers of gauge and check fixtures in the area. However, in 2012, Select Tool diversified its product line into automation and specialty tooling for the automotive, aerospace, and transportation industries. In 2014 the company built a new facility to accommodate this growth and further built an additional facility in 2016. Today, with over 100,000 square feet of manufacturing floor space, the company’s ability to control for quality and mitigate risk, due to its high level of vertical integration, has established it as one of the largest and most capable suppliers in North America.

International expansion has helped Select Tool to grow dramatically over the past six years. Approximately 70–75 per cent of its sales are international, primarily to the United States and Mexico. Select Tool has also experienced a tremendous increase in its number of employees, from 35 in 2008 to 235 at present. The company’s founders are Windsor locals who grew up with numerous family members already involved in the automotive industry. Select Tool’s Windsor location proved hugely beneficial because of the city’s renowned reputation as an automotive hub, and the talent pool that exists there in trades and manufacturing. Students in the area are also more likely to be skilled or interested in automation or manufacturing processes.

In 2016 Select Incorporated in Mexico as Select Tool de Mexico. It acquired a 24,000 square foot facility in July 2017. As of today the facility is operational, employs 15 personnel, and is expanding. The intent of the operation is to be a full service facility capable of all functions that are performed in Canada. To date Customer support and satisfaction with this move has been overwhelming. Based in Queretaro, Mexico, this central location is ideal to service existing and future Customers throughout the country.

Select Tool capitalizes on student interest in the automotive industry by providing employment opportunities to students from multiple high schools in Essex County. These opportunities are offered through the Ontario Youth Apprenticeship Program (OYAP), which allows students to begin training in a skilled trade while completing an Ontario Secondary School Diploma, and also allows employers to train the skilled workers they require. Select Tool’s program allows students to spend two months in the company’s CNC Machining department, two months in Fixtures, and two months in Automation. This rotation enables students to experience all three major aspects of the business, and gravitate towards the area that interests them most. Students are monitored and evaluated on the shop floor, and given monthly progress reviews. When students are hired back, they can choose where they wish to work based on what interested them most during their apprenticeship. The benefits of this program have not gone unnoticed by high schools, as most schools in the area advocate for their students to be included in the program. In addition, tours of the plant are frequently offered to high school students to continuously spark and maintain student interest in the automotive industry.

Select Tool recruits older students from St. Claire College, Fanshawe College, and many other colleges in the area. Regardless of which pool the employee is hired from, new employees are often taught many new skills on the job because the technology used at the plant is unique. The company seeks students who are hard-working, quick learners, and willing to learn new skills. Select Tool enjoys an excellent relationship with many high schools and colleges in Essex County due to its ability to offer exciting employment opportunities.

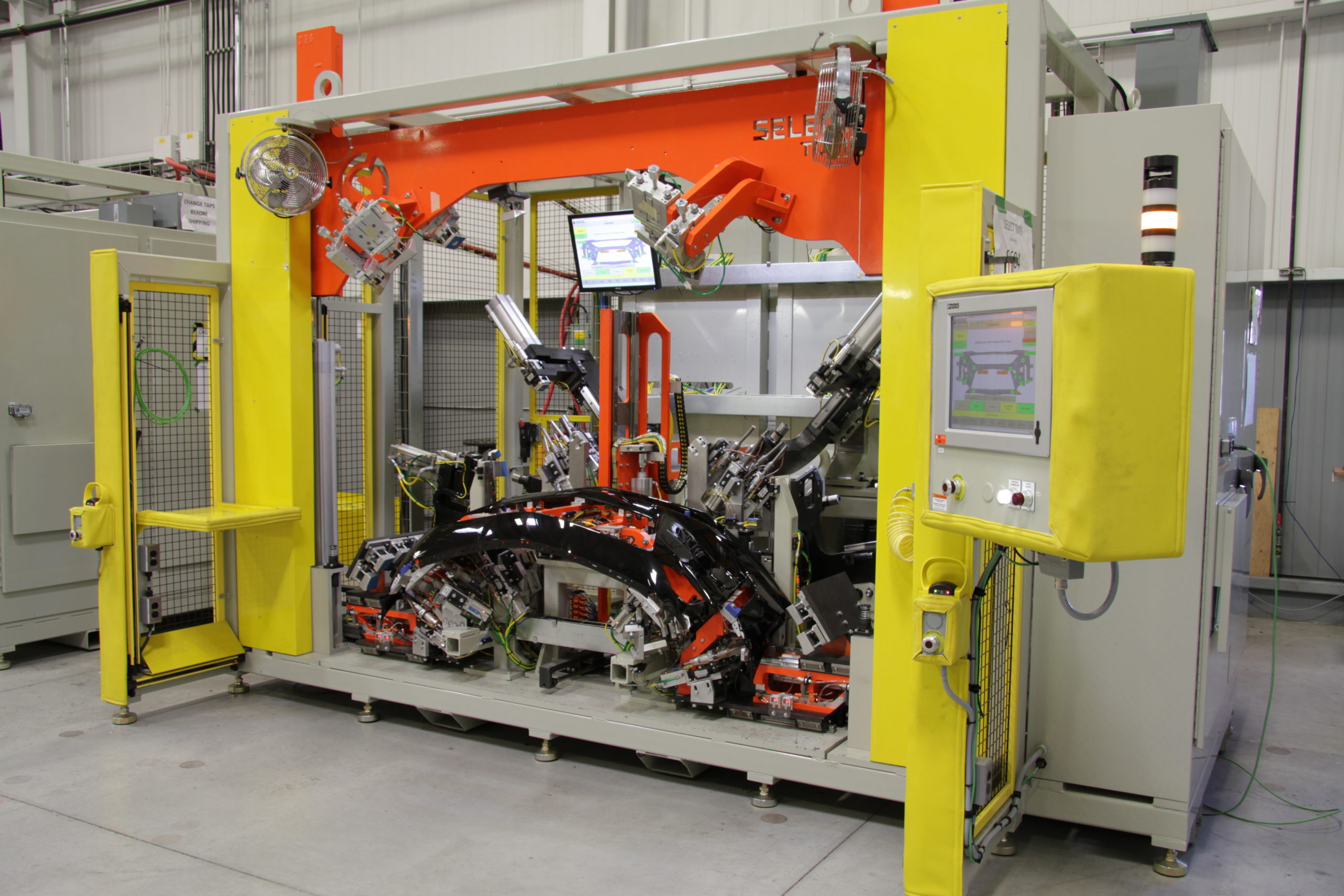

For over 20 years, Select Tool has developed its extensive expertise in the design and manufacturing of gauges and fixtures. As a provider for all of the major automotive OEMs and leading tier 1 suppliers in North America, Select Tool has become accustomed to meeting and exceeding the standards of these prominent customers. The firm’s gauges and fixtures are produced through a meticulous design and manufacturing process. All components are built in-house at the Advanced Manufacturing division. The company’s level of vertical integration streamlines the production flow and ensures that even the smallest components meet rigorous quality standards. Additionally, quality assurance inspections are performed in an on-site metrology laboratory.

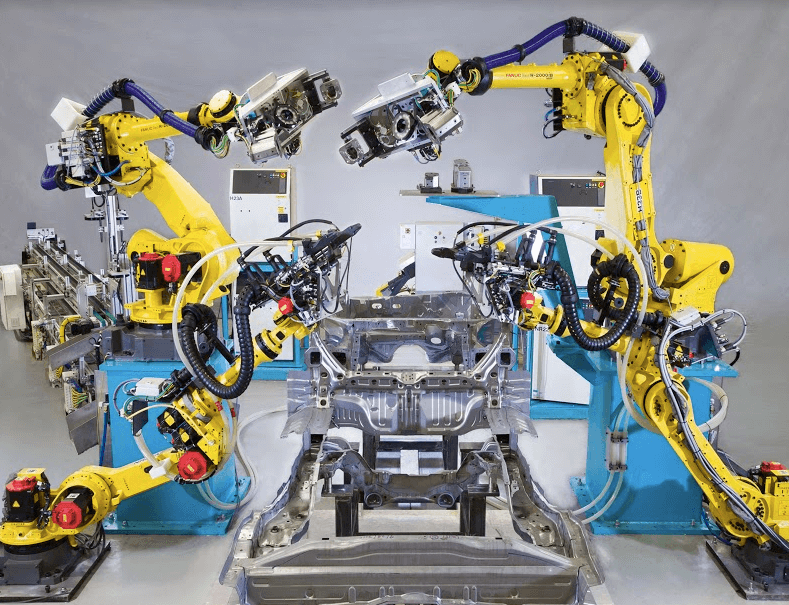

Select Tool’s automation systems are designed by a talented and experienced engineering team using many design tools including robotic simulation software. The engineering team is comprised of mechanical designers, electrical designers, and controls designers. This in-house technical expertise allows Select Tool to deliver high-quality and innovative automation solutions that exceed customer expectations. The automation cells and systems produced also place significant emphasis on safety, ergonomics, and cycle times. The Specialty Tooling division is responsible for developing any type of tooling required for various manufacturing challenges.

A recent trend that Select Tool hopes to capitalize on is the desire for consumers to lease a car rather than buy one. Many people prefer driving a new car every two to three years (i.e., leasing) as opposed to replacing a car they own every six to eight years (i.e., buying). Car companies no longer need to fully redesign the whole vehicle for a customer, but instead can replace various exterior car components with new and improved parts. This is referred to as mid cycle enhancements. This results in high demand for exterior car parts, which Select Tool manufactures this equipment for.

Moreover, as the automotive industry becomes more automated, Select Tool realizes the importance of embracing automation and the efficiency that it offers. With this aim in mind, the firm completed its Advanced Manufacturing division in 2016. This additional facility increased capacity so the company could accommodate larger programs, and significantly augmented its machining capabilities. The new facility is used by all manufacturing divisions to ensure that components and modules are built on time, and that they fully satisfy customers’ standards and expectations. Select Tool’s Human Resources department is proactively involved with government programs and funding, which greatly assist the company with its growth and expansion.

Giving back to the local community is another important focus for Select Tool, and the company is heavily involved with local charities. By linking with charities, high schools, and colleges in Essex County, Select Tool has had an extremely positive impact on the surrounding area—one which it plans to maintain as it achieves continued success in the manufacturing sector. Select Tool’s management believes that the firm’s growth will continue if it sticks to its operating philosophy, which centres on providing exceptional quality products, investing in employees and equipment, maintaining flexibility in achieving cost targets, pursuing innovative engineering and design, and demonstrating genuine concern for its customers’ success.

For more information about Select Tool Inc., visit their website.

Published: July 18, 2018

CenterLine

CenterLine is a manufacturer of custom automated welding and assembly lines, as well as resistance welding-related products. The firm is known worldwide as a leader in fastener welding technology, which is used in the production of automotive components.

Linear Transfer Automation

Based in Barrie, Ontario, Linear Transfer Automation is a global supplier of press transfer automation, blank feed systems, and press-to-press automation. Linear is able to customize its automation solutions to fit specific equipment geometry and requirements for customers.

Innovative Automation

Located in Barrie, Ontario, Innovative Automation Inc. is one of the most creative manufacturers of custom automation solutions in North America. It is Innovative Automation’s Vision to “Be the first choice provider of automation solutions to global leaders in manufacturing”. To ensure that it is equipped to handle even the most complex machine solutions required by its customers, Innovative Automation has an electrical systems design team, a mechanical design team, a programming team, and a mechanical build team.

BOS Innovations

BOS Innovations develops custom factory automation solutions to help companies reach greater levels of productivity and profitability. The company’s mission is to advance North American manufacturing through world class integration of automation systems with innovative engineering, build quality, and service.

Abuma Manufacturing Limited

Abuma Manufacturing Ltd (Abuma) is a Build-to-Print metal fabricator capable of manufacturing custom components. Abuma fabricates the metal components and upper-level assemblies and integrates additional outside services like surface coatings, electrical, pneumatics, and purchased equipment as required.