-

Headquarters -

1401 Dundas Street E, Woodstock, Ontario, N4S 8X8

-

Year established -

1992

-

NAICS -

332710 - Machine shops

-

Major expansions -

2002

-

Employees -

24

-

Exports -

US

-

Download -

Industrial Parts Manufacturing

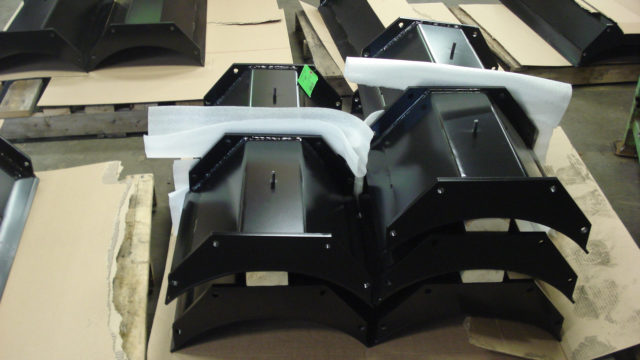

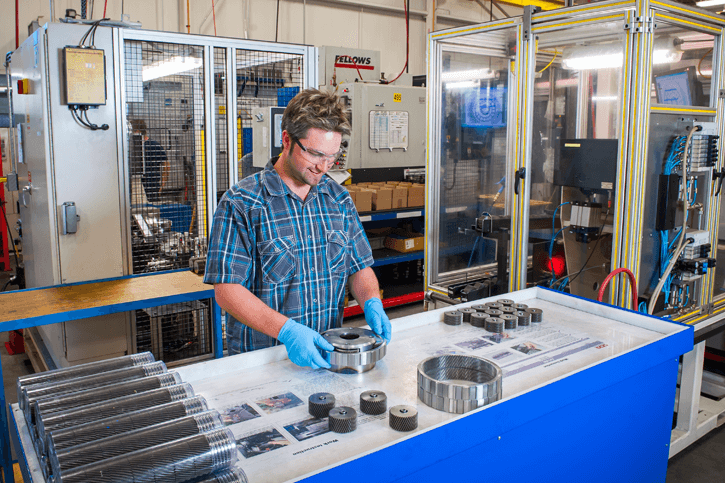

Industrial Parts Manufacturing specializes in CNC machining, general machining, welding and fabricating.

The attraction of “buying local” permeates many industries today. Manufacturers of forestry, mining, and construction equipment in Ontario can buy quality custom-built parts for their factory from a local manufacturing company, such as Industrial Parts Manufacturing (IPM). Specializing in computerized numerical control (CNC) machining, general machining, and welding, as well as fabricating, blasting, and painting, IPM supplies products to numerous manufacturing facilities in Ontario and the United States.

Founded in 1992, IPM moved to a new facility in Woodstock in 2002, and underwent a few expansions in that facility. In 2008, it received ISO 9001 certification from the International Organization of Standardization. The facility and its welders are also certified under the standards of the Canadian Welding Bureau. Business was going well and IPM was growing steadily until the 2008 financial crisis struck.

The aftermath of the financial crisis translated into substantial work to build IPM’s sales back to pre-2008 levels. However, the hard work and perseverance paid off, as the company not only recovered but grew as much as 50 per cent in the following three years. A major increase in IPM’s customer volume allowed for this tremendous surge in sales and an expansion of the company’s facility. The vast majority of IPM’s products (95 per cent) are shipped to customers in regions surrounding the facility in Woodstock and across Ontario. The remaining 5 per cent of products are exported to the United States.

IPM mission is to create world-class products for local clients that market their products worldwide. The Woodstock region is concentrated with numerous machining and parts manufacturers. Maintaining a competitive edge is essential for IPM to continue to be a supplier of choice. Similarly, “customer care” is key to its success. The company’s top priority is keeping its existing customers (and then, secondly, acquiring new accounts). IPM takes custom designs from clients and builds what they want, when they want it. Many of its customers increasingly favour specialized manufacturing production systems, while holding less and less inventory. Therefore, these customers expect products to be ready in very short periods of time. Investing in capital equipment, relationship building, and local clients ensures that IPM meets these shorter deadlines. Employees are encouraged to visit customer facilities to see their products “in action.” In this way, pride in workmanship is reinforced.

"A lot of companies can do what IPM can do," says a company spokesperson, “but few companies experience IPM's level of success.”

Maintaining a competitive edge is the firm’s secret. Accordingly, the company focuses on reducing lead times and keeping an eye on what customers are forecasting for their requirements in the long and short term.

In time, the company hopes to expand its facility, equipment, and staff. Yet finding the right employees—that is, those who can both work quickly and produce quality products that meet high expectations—can be a difficult task; for example, the company’s machinists must be able to not only operate but also set up the equipment they work with. IPM looks for qualified welders, trained machinists, and workers in the special trades with industry experience. It also hires some recent graduates from programs at post-secondary institutions like Fanshawe College and Conestoga College. Those with the right mindset are able to learn from the experienced employees at the company, and gain the experience and work ethic suitable for a career with IPM. Many of these graduates join IPM for their first job, and most stay on to become permanent employees. This practice makes for loyal workers and very low staff turnover.

IPM is unsure about the future of the Canadian manufacturing industry. It expects its significant growth in sales to level off in 2017, as pent-up demand catches up and some markets soften. However, the company remains optimistic, looking forward to planned expansions. One thing is for certain: any expansions and growth will be within Ontario, and IPM will work hard from this locale to remain the supplier of choice for the region’s manufacturing facilities.

For more information about Industrial Parts Manufacturing, visit their website.

Published: February 26, 2018

Hamill Machine Company

Hamill Machine Company Inc. is a diversified small manufacturer of custom machined parts and other machinery for a wide range of industries.

CMI Heavy Industries

CMI Heavy Industries is a leading provider of heavy fabricated, forged and cast machined components and assemblies.

Ontario Drive & Gear Ltd.

Designer and manufacturer of “the world’s most capable off-road vehicle,” Ontario Drive and Gear (ODG) is the world’s leader in amphibious, all-terrain vehicles and also produces noise-reduced transmission systems.

J&S Manufacturing

J&S Manufacturing is a mining equipment manufacturer, with in-house design capabilities that allow the firm to manufacture mobile equipment as well as technical custom equipment. The company’s motto is “Built to Perform”.

Timberland Equipment

Timberland Equipment is a global leader in the integrated design, manufacture and support of engineered winches, hoists, sheaves, derricks and tensioning equipment for the world’s most challenging infrastructure and capital equipment projects.