-

Headquarters -

25 Invicta Court., London ON, N6E 2T4, Canada

-

Year established -

2013

-

NAICS -

334110 - Computer and peripheral equipment manufacturing

-

Major expansions -

N/A

-

Employees -

15

-

Exports -

US, Mexico, China, New Zealand

-

Download -

FreePoint Technologies

FreePoint Technologies (FreePoint) is a technology firm located in London, Ontario. Established in 2013, FreePoint helps industrial and manufacturing firms join the Industrial Internet of Things (IIOT) revolution. They do this with their unique, “machine wearable” technology that connects machinery to the cloud, allowing for simple collection and analysis of data on existing machinery.

FreePoint Technologies Inc. (FreePoint) is a technology firm located in London, Ontario. Established in 2013, FreePoint helps industrial and manufacturing firms join the Industrial Internet of Things (IIoT) revolution with FreePoint’s unique, “machine wearable” technology that connects machinery to the cloud, allowing for simple collection and analysis of data on existing machinery. However, FreePoint is more than just the benefits of its products. The company is driven by an understanding of what manufacturing means to society, and what Industry 4.0 means for manufacturing.

Paul Hogenhoorn, the founder and owner of FreePoint, demonstrates these understandings and how they are at the core of everything the company does. FreePoint was founded on the principle that manufacturing is the driver of the middle class, a social centrepiece for employment and provision of basic goods. Hogenhoorn believes these underlying purposes must be kept in mind as Industry 4.0 changes the face of manufacturing.

FreePoint is taking a unique approach to Industry 4.0. While many companies’ Industry 4.0 solutions are extremely complex, FreePoint is moving in the opposite direction, maintaining that the heavy focus on technology and data often leaves a key factor—people—out of discussions about Industry 4.0. The first step is getting data from machines, but the second is getting data to people. Thus, FreePoint management assert that sophistication of the technology should come second to usability of the data for those operating IIoT machines.

FreePoint began operations five years ago, but the idea of the company was conceived long before that based on a simple question: if cellphones can provide ubiquitous information and power at low costs, why can’t the same technology be used to meet the needs of manufacturers? From this idea, FreePoint began developing its products with the shop floor in mind, kick-starting the democratization of Industry 4.0.

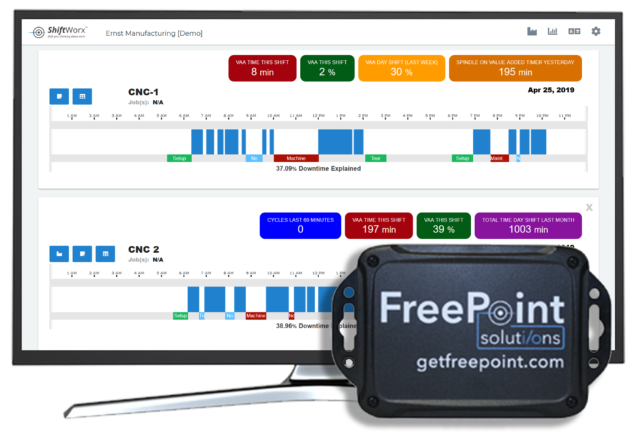

This mission is achieved through FreePoint’s two main products. The first is a simple remote input/output (I/O) device, often referred to as a black box, which is attached to existing machinery and allows any signal to be easily connected to a database. In fact, the company’s name stemmed from this idea of the black box being a “free I/O point” that allowed any I/O point to be freely connected to an existing IT infrastructure.

The advantage of this technology is that it allows data to be collected on legacy equipment. The average age of manufacturing machines on shop floors in Ontario is 28 years. Purchasing all new machines with built-in digital capabilities is rarely possible for manufacturers. Black box technology resolves this issue. Incredibly, the oldest machine FreePoint has connected to the cloud was built in 1914.

FreePoint’s customers maintain ownership of the data collected by the black box technology. To date, the technology has been added to over 1,000 machines, and collected over 1 billion lines of data. This data is invaluable for analyzing processes and efficiency, whether that analysis is done by the firms themselves or consulting companies.

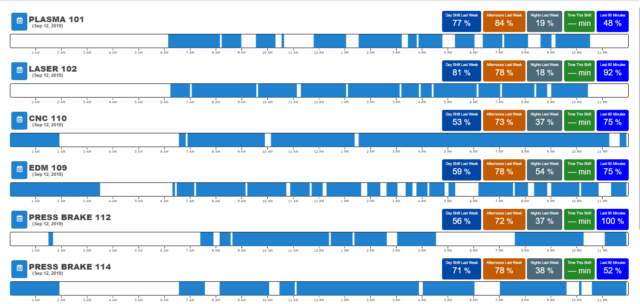

FreePoint’s second product is called ShiftWorx. This product addresses the issue of getting usable data into the hands of people. ShiftWorx is a software platform that organizes and analyzes data collected from black boxes. The interface allows data to be shared effectively and creates actionable information.

The ShiftWorx platform makes data visible to workers on the shop floor, giving them the opportunity to make physical changes to work processes in real time. This product embodies FreePoint’s belief that the machine operator is central to the information stream. Keeping in mind the digital upbringing of most millennials entering the workforce, FreePoint designed ShiftWorx to “gamify” the display of data on the shop floor, making it conducive to operators’ engagement and encouraging them to take pride in improving the operation of their machine. The combination of black box technology and the ShiftWorx platform represents FreePoint’s mantra for the adoption of IIoT: “measure, analyze, share.”

In addition to developing and installing its products, FreePoint also offers consulting services to optimize the use of its products and turn the data into actionable insights for the shop floor. The company often collects data over a period of three months in order to establish a baseline and then make informed decisions.

FreePoint’s products have an international presence, with 80 per cent of sales split between Canada and the United States, and the remainder in Mexico, China, and New Zealand. Hogenhoorn firmly believes that any nation that values its middle class would value FreePoint’s technology. Given this belief, he has plans to increase FreePoint’s international marketing in 2018, while continuing to grow the company domestically.

At the same time, FreePoint’s location is crucial to Hogenhoorn. London is a key Canadian manufacturing hub with a large IT community. He envisions FreePoint becoming “the Google of the plant floor,” and with this vision is the opportunity for London to become the IIoT epicentre of Canada. As part of the London community, FreePoint maintains strong relationships with local institutions of higher education like Fanshawe College and Western University.

Although FreePoint is a technology company, it consistently demonstrates that its main focus is people. Technologically, the company strives to meet people where they are at. Its purpose-driven products are grounded in the value of the worker. For FreePoint, the goal is to engage workers, restore dignity to labour, and reconnect manual work and meaning.

For more information about FreePoint Technologies, visit their website.

Published: July 25, 2018

Clearpath Robotics

Clearpath Robotics (Clearpath) designs and manufactures driverless vehicles for research and development. Solutions are used for research across mining, agriculture and military industries. OTTO Motors is a division of Clearpath, established in April 2016, to provide self-driving vehicles for light-load and heavy-load material transport in factories, warehouses, and distribution centres.

Abuma Manufacturing Limited

Abuma Manufacturing Ltd (Abuma) is a Build-to-Print metal fabricator capable of manufacturing custom components. Abuma fabricates the metal components and upper-level assemblies and integrates additional outside services like surface coatings, electrical, pneumatics, and purchased equipment as required.

BOS Innovations

BOS Innovations develops custom factory automation solutions to help companies reach greater levels of productivity and profitability. The company’s mission is to advance North American manufacturing through world class integration of automation systems with innovative engineering, build quality, and service.

CenterLine

CenterLine is a manufacturer of custom automated welding and assembly lines, as well as resistance welding-related products. The firm is known worldwide as a leader in fastener welding technology, which is used in the production of automotive components.

Linear Transfer Automation

Based in Barrie, Ontario, Linear Transfer Automation is a global supplier of press transfer automation, blank feed systems, and press-to-press automation. Linear is able to customize its automation solutions to fit specific equipment geometry and requirements for customers.