-

Headquarters -

415 Morton Drive, Windsor, ON, N9J 3T8

-

Year established -

1957

-

NAICS -

333519 - Other metalworking machinery manufacturing

-

Major expansions -

2017

-

Employees -

900

-

Exports -

US, Mexico, Brazil, EU, China, India

-

Download -

CenterLine

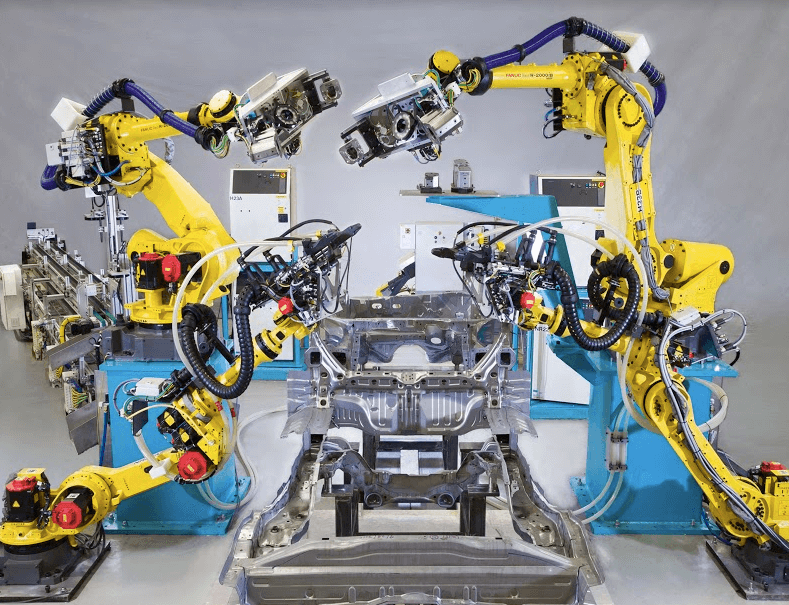

CenterLine is a manufacturer of custom automated welding and assembly lines, as well as resistance welding-related products. The firm is known worldwide as a leader in fastener welding technology, which is used in the production of automotive components.

The Windsor, Ontario area has long had a reputation for two great things: its strong, close-knit community and thriving automotive industry. CenterLine (Windsor) Limited (CenterLine) is a company that has helped build this reputation and continues to reinforce it today. As a manufacturer of custom automated welding and assembly lines, as well as resistance welding-related brand products, CenterLine is a key economic driver for Windsor.

Centred on a customer-focused approach to business, CenterLine primarily serves automotive original equipment manufacturers (OEMs) as well as tier suppliers. The company is known worldwide as a leader in fastener welding technology, which is used in the production of various automotive components. There are few vehicles on the road in North America that have not had some input from CenterLine at some point in the production process.

CenterLine was founded by Windsor locals Fred Wigle and Donald Beneteau in 1957, using 1,000 square feet of manufacturing space in downtown Windsor. Its initial projects included producing Chrysler ashtrays and Ford tail fins, but over time, the company shifted its focus to automation. In 1998, ownership was consolidated to the Beneteau family, and today Donald’s son, Michael, is the firm’s chief executive officer.

While the first 40 years of CenterLine’s operations consisted of steady, solid growth, the past two decades have seen its rapid expansion. Since 1998, the company has doubled in size and it now holds over 80 patents. This success can be attributed to a number of factors, but chief among them are CenterLine’s customer-focused approach and its ownership’s commitment to employees and the community. Both factors foster an environment of productivity and innovation. On a day-to-day basis, employees strive to uphold the reputation of CenterLine, which translates into quality products and customer service. Coupling this attitude with decades of experience in welding and robotics has propelled CenterLine to the forefront of its industry.

A common phrase heard at CenterLine, which originated with its founders, is, “make the customer a hero.” The company prides itself on never walking away from a customer, regardless of the financial implications. This strategy is highly valued by CenterLine’s customers because they operate in an industry where stakeholders are constantly looking for ways to minimize risk. Customers often approach CenterLine with their riskiest projects because they are confident in the team’s technological capabilities and reliability.

From an internal business standpoint, two management tactics that allow CenterLine to take this customer-first approach are reinvesting in the company and focusing on long-term goals. The Beneteau family members understand that reinvesting back into CenterLine signals to customers that they have confidence in the business and are willing to invest in its future success. Additionally, management sets long-term objectives so the team can focus on sustainable growth instead of honing in on short-term goals like quarterly profits; this allows project managers at CenterLine to be flexible with customers to ensure that projects are completed to all stakeholders’ satisfaction.

Another key driver of CenterLine’s growth is its commitment to its employees and community. In today’s competitive business landscape, finding and retaining the talent necessary for success in manufacturing is a big challenge for any company in Ontario. To ensure that graduates are qualified for the workforce, CenterLine is closely involved with local high schools and post-secondary institutions. The company hosts an annual Grade 9 day at a local high school, where it introduces students to the trades and the different types of career opportunities in advanced manufacturing. In addition to offering the largest apprenticeship program in the Windsor area, CenterLine partners with St. Clair College and several Ontario universities to assist with curriculum development, funding, instructing opportunities, and co-op program support.

Not only does CenterLine put significant effort into preparing individuals for the workforce, it also ensures that employees have a positive experience once they begin working for the company. Initiatives like the Healthy Lunch Program, “Lunch and Learn” sessions, and annual Christmas parties all contribute to a healthy working environment.

This exciting, collaborative workplace makes people proud to work at CenterLine, and encourages them to give back to the community. Many employees at CenterLine are heavily involved in the “For Inspiration and Recognition of Science and Technology” (FIRST) Robotics and LEGO League competitions. They use their expertise in robotics to team up with high school students and pique their interest in science, technology, engineering, and mathematics. This involvement led to a thrilling achievement in 2018, when a CenterLine-sponsored team took first place at the FIRST Robotics competition at Western University.

Like any company, CenterLine must navigate certain challenges if it wishes to maintain its current level of growth moving forward. Because its equipment is primarily focused on welding, CenterLine needs to stay on top of trends in material composition changes in vehicles. Automotive companies are always seeking to make vehicles lighter, stronger, and more durable, and this means that CenterLine’s equipment must accommodate different materials. The company manages this dynamic requirement by keeping its employees up to date with the latest technology, and working closely with stakeholders in the supply chain.

Another challenge is dealing with the loss of many experienced, tenured employees as they approach retirement. However, CenterLine has been taking steps to ensure this issue can be overcome. Its workforce encompasses a wide range of ages and the firm hires young employees on a consistent basis. Moreover, CenterLine invests in many of its “rising stars” by grooming them for senior positions and assisting with their further education, such as MBA or Master of Engineering degrees.

What does the future hold for CenterLine? The company realizes that there is a significant opportunity to continue expanding globally. With OEMs producing vehicles across the globe, these firms are expressing the desire to use the same production processes in all of their factories. CenterLine’s reputation for innovation and a customer-focused approach make it the perfect candidate for becoming an even bigger partner in the global supply chain for OEMs.

Two other trends that CenterLine is looking to capitalize on are the automation and electrification of vehicles. The industry is experiencing a drastic shift in terms of what finished vehicles look like, which means the company has a promising opportunity to leverage its innovation to provide value to customers. CenterLine is well aware of this possibility, and already lists a major electric vehicle producer as one of its customers.

CenterLine contributes to Ontario manufacturing as a whole through the advancement of knowledge and innovation in the industry. By creating new products and solving problems, it helps its customers stay competitive in an increasingly challenging market. The firm also provides Ontarians with well-paid, knowledge-based jobs, which increases the quality of the province’s workforce. Ultimately, however, CenterLine’s owners recognize that the primary role they play is providing stable employment for individuals and families in the Windsor region; these people depend on them to manage CenterLine properly so it can continue as a thriving business where they are proud to work.

For more information about CenterLine, visit their website.

Published: June 20, 2018

Armo-Tool

Armo Tool is a Tier 2 supplier and provider of “one-stop” precision tooling solutions, from small components to large machines that build Tier 1 parts. It has been family owned and operated since inception.

Samco Machinery

Samco Machinery is a global innovator in producing roll forming machinery and custom built material handling solutions. In business for over 45 years and maintaining ISO 9001 certification, our services include: consultation, engineering, installation, training, commissioning, ongoing maintenance, support, and parts.

Innovative Automation

Located in Barrie, Ontario, Innovative Automation Inc. is one of the most creative manufacturers of custom automation solutions in North America. It is Innovative Automation’s Vision to “Be the first choice provider of automation solutions to global leaders in manufacturing”. To ensure that it is equipped to handle even the most complex machine solutions required by its customers, Innovative Automation has an electrical systems design team, a mechanical design team, a programming team, and a mechanical build team.

Linear Transfer Automation

Based in Barrie, Ontario, Linear Transfer Automation is a global supplier of press transfer automation, blank feed systems, and press-to-press automation. Linear is able to customize its automation solutions to fit specific equipment geometry and requirements for customers.

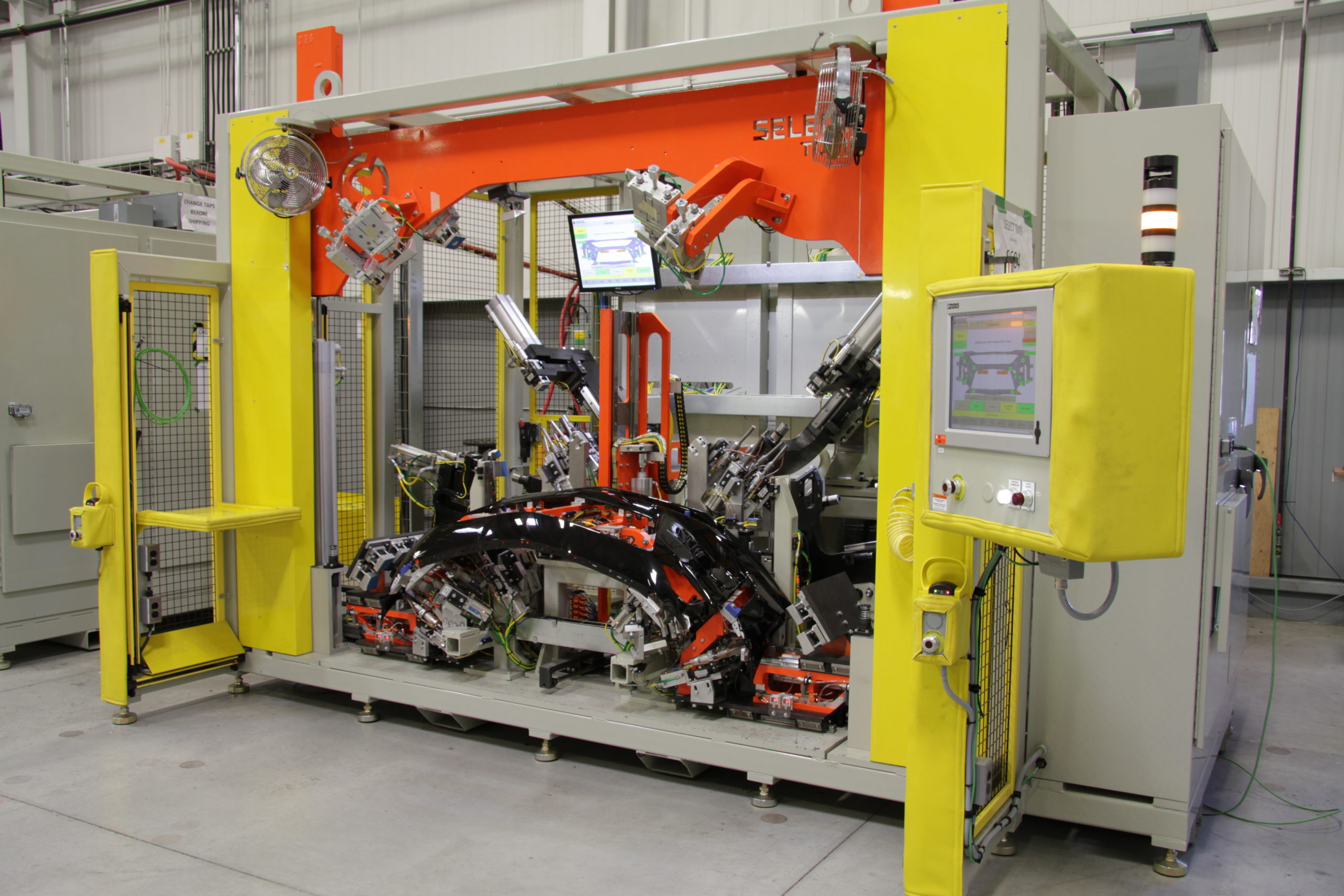

Select Tool Inc.

Select Tool is a manufacturer that has developed a reputation for providing high quality full-service gauges, fixtures, automation, and specialty tooling for the automotive, aerospace, and transportation industries.