-

Headquarters -

11 Director Ct, Woodbridge, ON, L4L 4S5

-

Year established -

1996

-

NAICS -

311814 - Commercial bakeries and frozen bakery product manufacturing

-

Major expansions -

1999, 2003, 2009

-

Employees -

200

-

Exports -

United States

-

Download -

Ozery Family Bakery

Ozery Family Bakery is an innovative baked goods manufacturer based in Vaughan. The company grew from a 700 square foot sandwich shop into a 100,000 square foot state-of-the-art factory within 25 years through innovation, automation, and building an inclusive company culture.

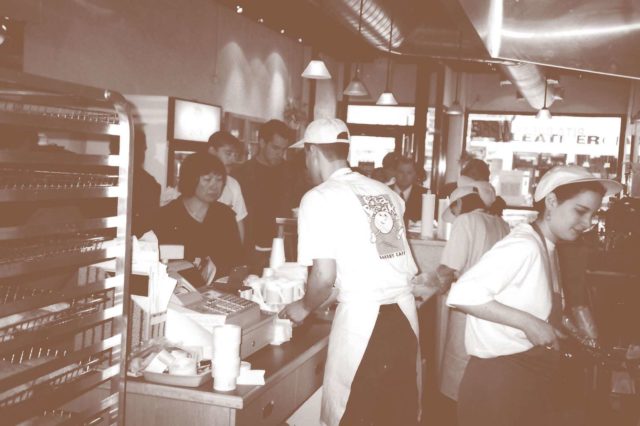

When Al Ozery and his son Alon opened Pita Break in 1996, they had no idea this sandwich shop that made 200 pitas a day by hand would become a full-fledged manufacturer producing 10,000 pita breads an hour on highly automated production lines.

The father and son team, later joined by Alon’s brother Guy Ozery, founded the business using $50,000 of their personal savings and a $100,000 small-business loan guaranteed by the federal government. Within a few years, the demand for their pita breads was growing so quickly, even more than their sandwiches, that the owners decided to switch to wholesale business altogether and focus on pita bread products. They closed the restaurant in 1999 and moved into a 4,000 square foot facility in Vaughan and re-branded the company as Ozery Family Bakery (“Ozery”).

Today Ozery operates a 100,000 square foot state-of-the-art facility in Vaughan. Alon and Guy Ozery run the company, which employs about 200 people. Ozery is known for its innovative baked goods such as Morning Rounds, OneBuns, and Lavash crackers. These products are manufactured by custom-designed automated systems that emulate the hand made products that got the company its start. They are sold to major coffee shop chains, supermarkets and health food stores across Canada and the United States. About half of the sales take place south of the border. This year Ozery is celebrating its 25th year in business.

The company’s growth from a 700 square foot sandwich shop into a 100,000 square foot state-of-the-art factory within 25 years has been possible through continuous innovation, incremental automation, and the owners’ entrepreneurial spirit and values that built an inclusive company culture.

When the company moved to its first Vaughan plant in 1999, the owners had limited resources. They purchased several pre-owned machines but most of the processes still relied on manual labour. In the early 2000s, the company pitched the concept of an innovative product line, thin and pre-sliced sandwich buns (OneBuns), to a Canadian customer and launched the product within a year. Thin buns created a new segment in the baked goods market and put the company on a growth trajectory.

This growth trajectory required Ozery to explore automated production systems to remain competitive. As current CEO Guy Ozery explains, “innovation without automation was not sufficient; we couldn’t have successfully competed in the U.S. market without the latter.” However, finding automated systems that could emulate hand-made pita breads was difficult. In fact, the systems Ozery needed were not even available.

We went through a lot of people to get to the person we needed. The moment you meet the right person, whether that person has the right technology or the right mindset, then things start to come together.

The owners began speaking with as many people in their network as they could to identify the right supplier to help them build a system from scratch. There was a period of trial and error. The owners kept looking for a supplier that could deliver exactly what they needed. “We went through a lot of people to get to the person we needed. The moment you meet the right person, whether that person has the right technology or the right mindset, then things start to come together,” says Guy Ozery.

A local company with no prior experience building a production line for a commercial bakery built one that met Ozery’s requirements. After a few test runs and a few months of small but important adjustments, the owners were happy with the result.

After that first line came into operation, the company kept on investing in incremental automation projects. Ozery worked with several innovative Canadian manufacturers in that process who helped them put together new automated production lines. Meanwhile, the company launched new and innovative frozen, gluten-free, and keto-friendly products. Guy Ozery underlines that harnessing their business connections, attending industry conferences and trade shows, and having business mentors helped them identify the right equipment suppliers for the automation projects. For each project, the firm targets to increase production volume by 30 per cent. Approaching automation in an incremental fashion allows the company to better match supply to demand.

Beyond innovation and automation, the other important factor behind Ozery’s successful growth has been its ability to build a strong company culture that helps it attract high-quality talent and achieve high retention rates. Guy Ozery highlights that building a strong company culture is more difficult than product innovation and finding new equipment. According to him, the firm culture has to reflect the owners’ own values and always be a part of the daily discussion. He adds that one of the proudest moments in the company’s history for him was when they were able to extend health benefits to their employees for the first time. Later, the company also initiated an employee profit-sharing program which continues to date.

In 2019, the company became a certified B Corporation, which means it uses profit and growth to make a positive impact on employees, communities and the environment (learn more about certified B Corporations here). Guy Ozery says B Corporation certification enables the company to maintain a path defined by values while hitting growth targets.

Ozery received its first government grant in 2020 to implement risk mitigation measures to protect its employees from the pandemic. Thanks to these measures, there have been no outbreaks at the plant and in four instances where employees contracted the virus outside the plant, they were successful in preventing the spread inside. Government wage subsidies have helped Ozery avoid laying off any employees during the pandemic.

Looking beyond the pandemic, Ozery strives to continue innovating and producing flavourful and healthy products, and to stay on track to improve its positive impact on the well-being of the employees, community, and environment. The company is excited to implement a new automated packaging system and to launch their new gluten-free and keto-friendly (Supper Seed Crunch) products in early 2021. Ozery’s move to automation while maintaining the artisanal taste of its products and company values is a testament to the possibilities for family owned establishments across Ontario.

For more information about Ozery Family Bakery, visit their website.

Published: March 16, 2021

Sweets from the Earth

Sweets from the Earth is a family-owned, vegan specialty baked goods manufacturer with over 150 types of desserts produced.

Crystal Fountains

Crystal Fountains is a third generation, family-owned company that designs and builds internationally recognized water features attracting millions of visitors each year.

Nuform Building Technologies

Nuform Building Technologies is North America’s leading manufacturer of finished concrete forming systems, providing services of estimating, design, technical assistance, transportation and logistics, and onsite field training.

Unilux VFC

Owned by VAST Industrial Corporation, Unilux VFC is a manufacturer of vertical fan coil units, specializing in the design and production of these units for individual condominiums.