-

Headquarters -

Unit 4 - 1621 McEwen Drive, Whitby, Ontario, L1N 9A5

-

Year established -

2017

-

NAICS -

333248 - All other industrial machinery manufacturing

-

Major expansions -

N/A

-

Employees -

5

-

Exports -

US

-

Download -

Next Manufacturing

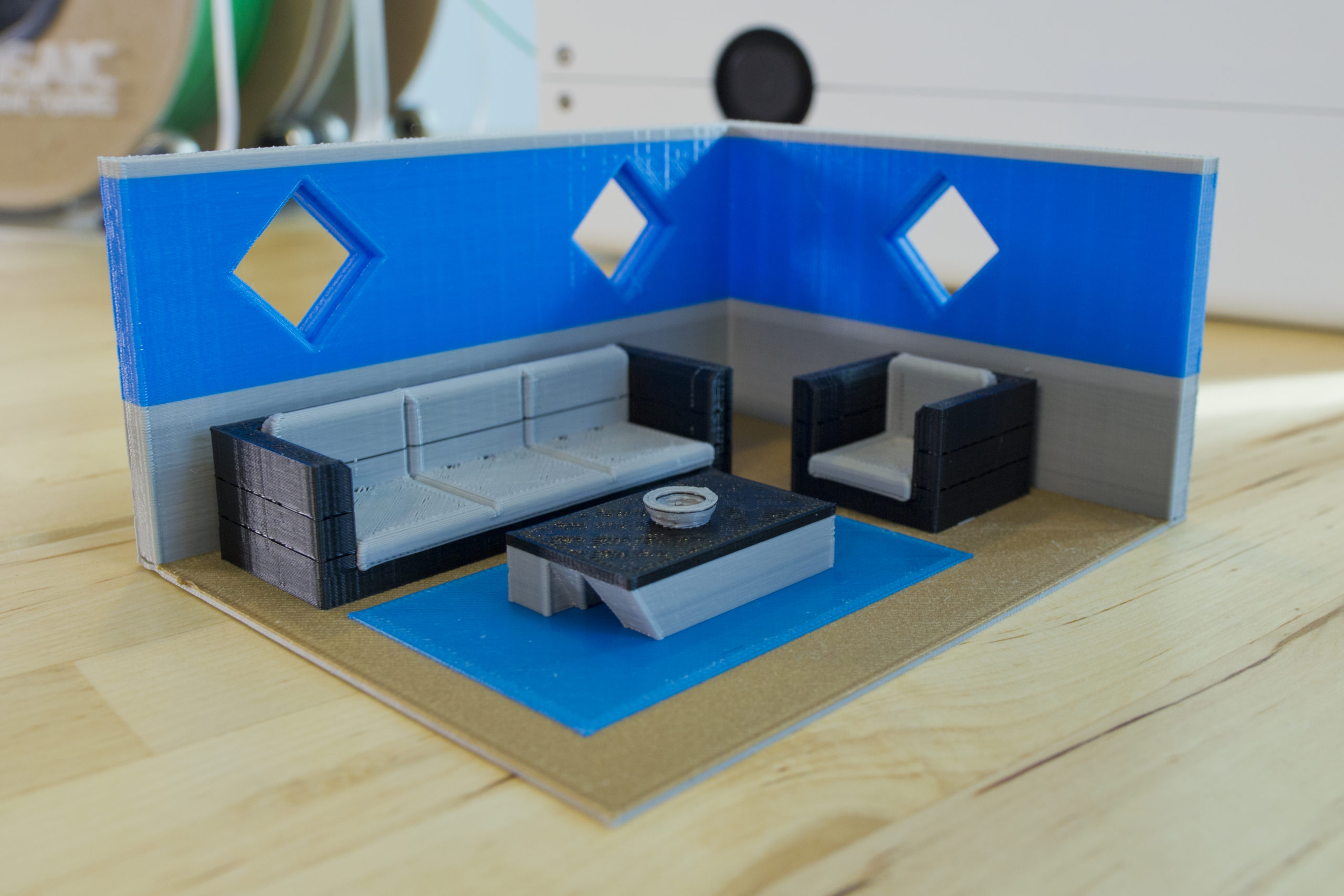

Headquartered in Whitby, Ontario, Next Manufacturing Inc. specializes in fused deposition modeling, a process that enables 3D printers to manufacture products by depositing melted material in a predetermined path one layer at a time.

In just three years, Next Manufacturing founder, Brandon Phinney, has expanded the 3D printing business that he started in-house to the point where it now has leased headquarters in Whitby, Ont., a U.S. facility and manufacturing space in Port Perry, Ontario. The company, which specializes in fused deposition modeling (FDM), is constantly researching materials, production processes and applications of 3D printing in order to develop new opportunities for this method of manufacturing. Next Manufacturing’s primary goal is to use its expertise, innovation and 18+ years of combined industry experience across its team to lower its customers’ costs.

The company was founded by Phinney in 2017 and he began by building a strong customer base in the United States. In response to the firm’s rapid expansion of its customer base in the U.S., Next Manufacturing set up distributors there so that they could better serve their American customers. Most recently, Next Manufacturing has connected with European distributors who will represent their products and services in the European Union.

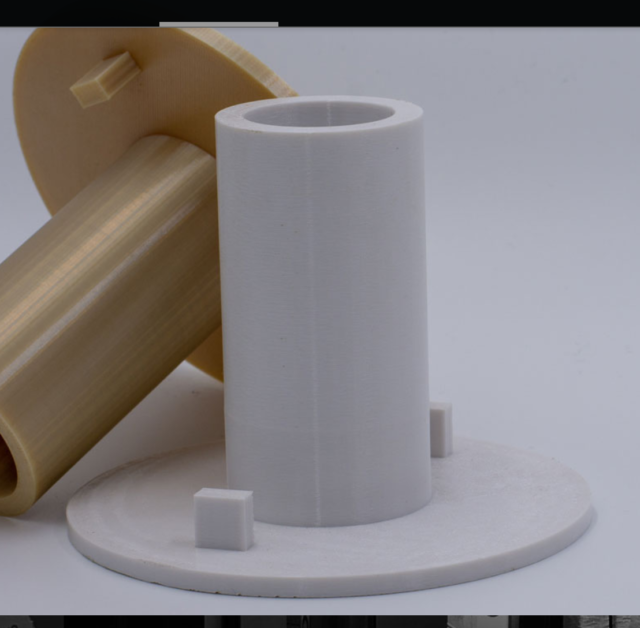

FDM is a process that enables 3D printers to manufacture products by depositing melted material in a predetermined path one layer at a time. A spool of filament is loaded into the printer and then transferred to the extrusion head and nozzle, where the filament melts. The extrusion head is capable of moving along three axes and ejects the melted material in extremely thin strands. These thin strands are deposited in predetermined locations and are then left to cool and solidify. This production process is most widely used for rapid prototyping, end-use parts, and manufacturing assembly aids and tools.

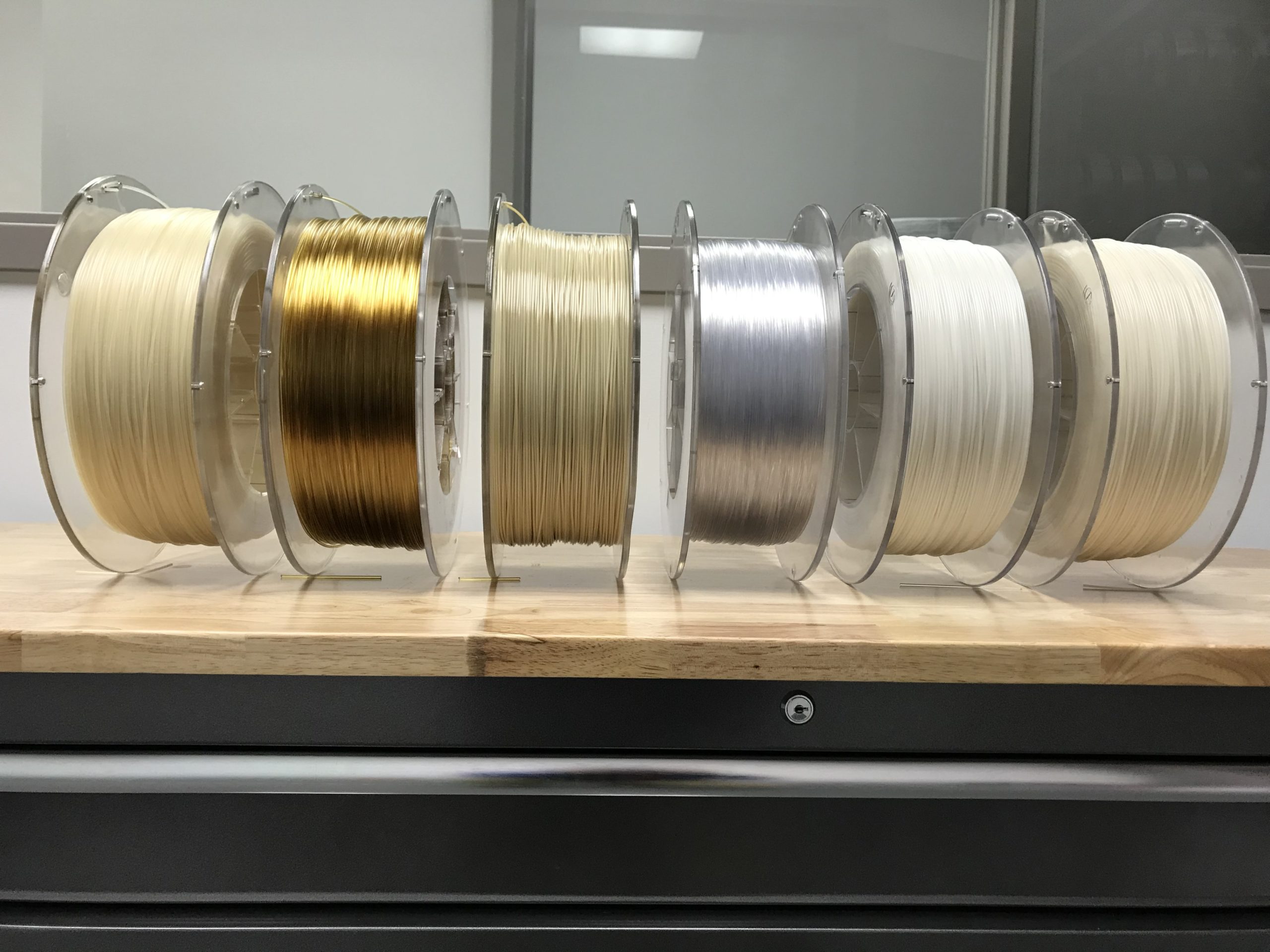

Next Manufacturing has also begun offering its customers the option of purchasing its filaments. The company’s R&D projects have enabled it to begin manufacturing filaments that are commonly used in the 3D printing process as well as innovative filaments for unique customer needs. The firm’s expertise and experience with 3D printing machines and the production process also enables Next Manufacturing to offer its customers high-quality custom filament and machine maintenance services.

The majority of Next Manufacturing’s revenue is comprised of repeat business from a small collection of customers.

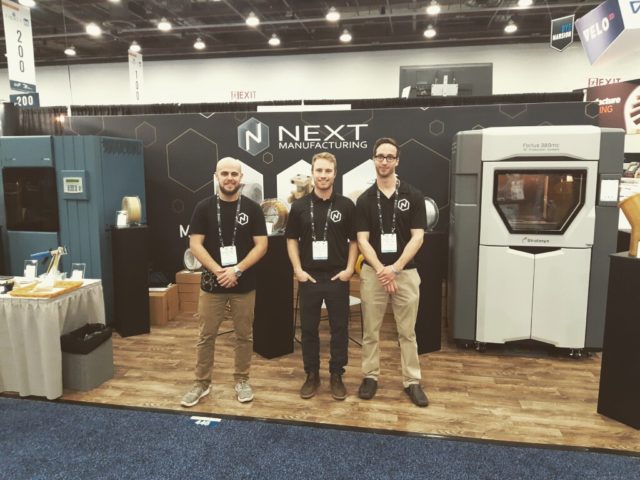

The firm’s primary marketing strategy is to display its products at trade shows because it is able to demonstrate the benefits of additive manufacturing in-person to potential customers. In addition to participating in the Canadian Manufacturing Technology Show, Next Manufacturing has recently attended trade shows in Frankfurt, Germany and Detroit as it looks to expand. The firm currently exports approximately 70 percent of its sales, almost exclusively to U.S. customers. Although Next Manufacturing plans to continue its rapid growth, the firm is currently operating at capacity and recognizes the need to increase its workforce.

Next Manufacturing currently employs five people, all of whom are responsible for multiple aspects of the business as the firm continues to scale up. The small workforce has resulted in a very tight-knit, family environment at Next Manufacturing, and Phinney is intent on maintaining this workplace culture as he looks to hire new employees. The firm has not yet developed relationships with educational or research institutions but plans to pursue these types of relationships moving forward. Next Manufacturing believes that developing relationships with various institutions will assist with the hiring process and further enhance the firm’s research capabilities.

The company is confident there are significant growth opportunities for open-source 3D printers, which would increase the demand for the firm’s filaments. This belief comes from the fact that a large portion of the proprietary software and hardware contained in 3D printers was patented in the late 1990s and will soon be expiring. To fully capitalize on this potential opportunity, the company’s primary short-term goal is to increase its workforce. It also intends to learn about government programs and organizations that are available to help it grow. Given the success and growth experience by Next Manufacturing over the past three years without any external assistance, the future looks promising for the firm as it aims to better utilize the resources available to manufacturers in Ontario.

For more information about Next Manufacturing, visit their website.

Published: June 9, 2020

Mosaic Manufacturing

Mosaic Manufacturing revolutionized the world of desktop 3D printers with the "Palette", an accessory for 3D printers that enables them to create multi-colour and multi-filament objects.

Mabel’s Labels

Founded by 4 moms, Mabel’s Labels designs, manufactures, markets and distributes personalized name labels and tags for children’s belongings. It is the creator of the market, and its leader.

FASTSIGNS of Windsor

FastSigns of Windsor offers full-service solutions in graphic design, signs, promotional products and custom solutions to fit every clients’ marketing needs.

London Mat Industries

London Mat Industries Ltd (London Mat) is the manufacturer of the world famous “MATEX” Treadle Switches, used on Buses, Trains and Trams for door safety, opening and passenger counting.

Angstrom Engineering

Angstrom Engineering Inc. is a leading manufacturer of thin film vacuum deposition equipment and vacuum chambers equipment. The firm specializes in designing, manufacturing, selling and servicing machines that deposit thin films, (growing layers of materials on a substrate with thicknesses that can range from less than one nanometer to several microns).