-

Headquarters -

152 Harry Bye Blvd, Mount Forest, Ontario, N0G 2L0

-

Year established -

1999

-

NAICS -

326198 - All other plastic product manufacturing

-

Major expansions -

2017

-

Employees -

20

-

Exports -

N/A

-

Download -

Molok North America

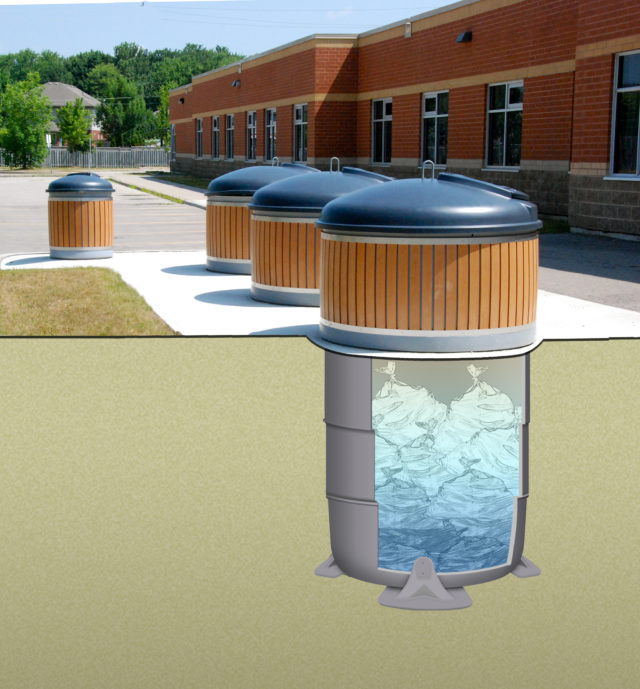

Molok is a new generation designer and manufacturer of the original semi-underground waste containment systems.

From cities and national parks to restaurants and university campuses, Molok North America Ltd. (Molok NA) keeps them all pristine with its array of waste storage systems. Molok NA’s facilities are located in Mount Forest Ontario, and its achievements include being included in Canada’s “Profit 500” list. However, for the company’s chief executive officer, Marja Hillis, the road to becoming one of Canada’s “Top Female Entrepreneurs” was not always an easy one.

In the 1980s, Hillis’ father, Veikko Salli, owned numerous restaurants and fitness centres in Finland. His office offered a view of a nearby dumpster, with the accompanying birds, rats, overflowing trash, and smell. “There has to be a better way [to store garbage],” he declared. After searching for a solution and uncovering no results, Salli resolved to invent a solution himself, and the Molok container was born. Two-thirds of the container are underground, thereby cooling the waste and reducing odours in the summer, while also preventing freezing in the winter. The container’s innovative design increases its capacity by five times and is more hygienic compared to an above-ground container, as well as enhancing visual appeal.

Hillis was Molok’s first champion and sales representative. Initially, funds were limited. Hillis was also managing a fitness centre that was floundering in the global recession. “And the only person I didn’t pay was myself,” she recalls. When she came to Canada in 1997, it was as a single mother with a one-year-old daughter. Hillis knew one person on the whole continent, but she was determined to introduce Molok containers to the North American market. “[It was hard] trying to sell my dad’s product in a 99 per cent male market,” she admits. Initially, people didn’t take Hillis or her product seriously. “There were lots of struggles . . . . If you’re female, you must work harder to prove yourself. But I always had a vision, and everything I did, I did according to that vision.” Already a full-time mother and entrepreneur, Hillis decided to pursue a degree in French at the University of Waterloo, with a minor in fine arts.

With time, word about Molok containers began to spread and sales soared. Although the company’s basic product research and development is still conducted in Finland, Molok NA provides “Canadianized” solutions. Bear-proof lids for national and provincial parks, such as Algonquin Provincial Park, are a prime example. In a partnership with the Montreal branch of the Big Brothers Big Sisters organization, Molok NA also developed donated clothing containers that save space, and protect against rain, and thieves.

Deceptively simple in concept, Molok containers are difficult to imitate in practice. There are hundreds of parts to the plastic containers, every one of which has arrived at its current form through decades of research and innovation. With characteristic magnanimity, however, Hillis says that she would welcome competitors. “Even though we have only a few repeat customers because these things last forever,” she explains, “it would take generations and generations to sell to everyone. Good competitors help spread the word.”

Hillis is equally generous with her 20 employees, saying, “They’re like family here.” Every year, she spends days preparing a Christmas feast for her staff and their families, as well as several barbecues throughout the year. The quality of the employees is a key reason for Molok NA’s rural Southwestern Ontario location. “The work ethics are just better here,” Hillis says. “People are loyal; we have employees that have been with the Molok family for over ten years.” Mount Forest is an excellent location for other reasons too. The unincorporated community is small, but there is a critical mass of manufacturing in the area. Mount Forest is also a 90-minute drive from the Toronto Pearson International Airport and even closer to Kitchener-Waterloo, and development charges for businesses are lower than those of larger cities. “It makes me so mad when people say manufacturing is dead in Ontario or Canada,” Hillis says. “When you go offshore, sure you’d get something cheaper, but you’re not in any kind of control over quality or delivery.” Dealing with local businesses is much better, she says: “As long as you keep innovating, and taking advantage of government programs like [the Scientific Research and Experimental Development] program (SR&ED), you’ll stay alive. . . . There are a lot of people here. Why [would] you go somewhere else?”

Conventional success notwithstanding, Hillis is continuously driven by a thirst for learning and growth, and has recently she returned to school for her executive MBA. Like Hillis, Molok NA is always growing, ready for whatever the future may bring.

Update:

In 2019, Molok North America celebrated its 20th year in operations. For its recent success, the firm has been recognized with many high-profile awards such as Business Worldwide’s Most Innovative CEO award in 2016 and The New Economy’s Most Innovative Waste Company award in 2017.

In 2017, Molok began construction on additional office space, bringing the firm’s total facility space to 50,000 sq. ft. Additionally, the new offices are located on a large plot of land that will allow the firm to continue to expand well into the future.

In March 2018, Molok North America’s Founder and CEO, Marja Hillis, passed away. Her partner, Mark Hillis, has since assumed the position of CEO.

For more information about Molok North America, visit their website.

Published: August 30, 2016

e.Hofmann Plastics Inc.

Innovation and automation. Paul Kalia, chief executive officer at e.Hofmann Plastics Inc. (Hofmann Plastics), notes that these two ideals are the keys to running any successful manufacturing business, and the aims that drive his company’s strategy. The company is in what Kalia refers to as the “rigid packaging business”. It manufactures plastic buckets for industrial markets (such as the orange buckets seen at Home Depot) and plastic packaging for the food and beverage industry. However, Kalia does not see Hofmann Plastics as a plastics company; instead, he views it as a technology company that is constantly innovating and looking for new ways to solve problems.

Harco Enterprises Limited

Harco is fourth-generation family business which operates two distinct divisions: Plastic Injection Molding and Process & Supply, which distributes sanitary processing equipment and components. The firm has a flexible product line, and is always looking for new market opportunities to take advantage of.

Nuform Building Technologies

Nuform Building Technologies is North America’s leading manufacturer of finished concrete forming systems, providing services of estimating, design, technical assistance, transportation and logistics, and onsite field training.

WEGU Manufacturing Inc.

WEGU Inc. is a multi-international manufacturer of molded rubber and plastic products. Product design assistance, engineering, tooling development, prototyping, testing and manufacturing, and materials analysis, are all offered in house. WEGU Inc. prides itself on the ability to consistently meet all of their client’s physical and chemical requirements for product durability, flexibility, noise and vibration mitigation, and abrasion resistance.

Direct Coil

Direct Coil manufactures commercial and industrial finned tube heat exchangers, as well as custom engineered refrigeration and heat transfer equipment.