-

Headquarters -

258 McBrine Drive, Kitchener, Ontario, N2R 1H8

-

Year established -

1996

-

NAICS -

332619 - Other fabricated wire product manufacturing

-

Major expansions -

2019

-

Employees -

100

-

Exports -

US, Asia-Pacific

-

Download -

LEONI Elocab Ltd

Located in Kitchener, Ontario, LEONI Elocab Limited is undergoing its second major expansion in less than a decade. The firm is the only Canadian division of LEONI Group, a global provider of products, solutions, and services for both energy and data management in various industries. LEONI Elocab offers a unique contribution to this global network by manufacturing customized cables and cable assemblies, providing a case-specific solution for every customer.

Located in Kitchener, Ontario, LEONI Elocab Limited is undergoing its second major expansion in less than a decade. The firm is the only Canadian division of LEONI Group, a global provider of products, solutions, and services for both energy and data management in various industries. With foundations going back over 400 years, LEONI Group originally manufactured gold and silver strands for uniforms, so processing copper wires for cables was a logical progression for the firm. Today, LEONI Group has grown to employ more than 95,000 workers in 32 countries. LEONI Elocab offers a unique contribution to this global network by manufacturing customized cables and cable assemblies, providing a case-specific solution for every customer.

LEONI Group entered the Canadian market in 2001 through its acquisition of Elocab Sonderkabel (Sonderkabel), a privately owned firm in Kitchener, Ontario. Established in a shoe warehouse in 1996, Sonderkabel grew to 12 employees before it was acquired. Being located in Kitchener greatly assisted the firm’s growth, allowing it to reach a larger pool of potential customers due to Kitchener’s relative proximity to the U.S. border and the American automotive hub, Detroit. After Sonderkabel became LEONI Elocab, LEONI Group imported a significant amount of advanced German technology and equipment to the newly acquired firm, adding substantial value to its existing operations. LEONI Elocab’s current President, Lukas von Arx, began leading the company in September of 2016.

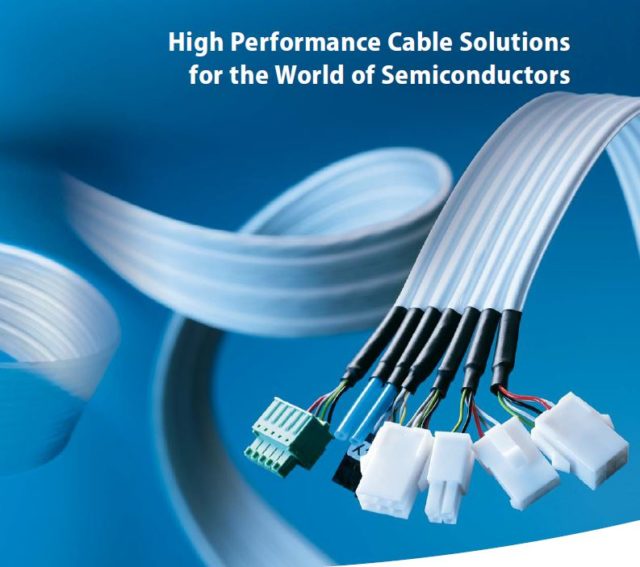

LEONI Elocab offers no standard, off-the-shelf products, choosing instead to maximize its unique ability to customize all aspects of its offerings. Apart from its sister company in Germany (LEONI Elocab GmbH), LEONI Elocab is the only division of LEONI Group that caters exclusively to customers seeking customized products; this has resulted in LEONI Elocab being entirely responsible for the Group’s customized cable sales in North and South America, while its sister firm covers the European market. LEONI Elocab has steadily expanded its manufacturing capabilities every year and can now produce cables that satisfy a wide range of requirements. For example, the firm can manufacture cables that must satisfy minimal diameter requirements (micro miniature), cables that have stringent cleanliness guidelines, or cables that are expected to withstand extreme torque, flex or pressure on a daily basis. Customers of LEONI Elocab appreciate the quality of the firm’s products since they do not have to worry about system shutdowns or setbacks that result from a cable failure.

The custom cables produced by LEONI Elocab are used in a wide variety of industries—including semi-conductor, healthcare diagnostics, industrial, and automation—helping the firm to develop many diverse relationships. The majority of the firm’s customers are Fortune 500 companies that are leaders within their respective industries, which speaks to the quality of LEONI Elocab’s cables. Recent growth experienced by the firm can be attributed to the acquisition of new customers who require custom solutions, and the growth of loyal customers who appreciate the quality of LEONI Elocab’s products. Von Arx explains that the greatest value LEONI Elocab offers its customers is the firm’s commitment to being a solution provider rather than just another cable manufacturer. The company’s customer-focused approach enables it to provide a unique solution for every potential customer with a cable that cannot fulfill its purpose or particular application. Many companies sell cables, but the customer experience and commitment to customer success is what sets LEONI Elocab apart from its competitors.

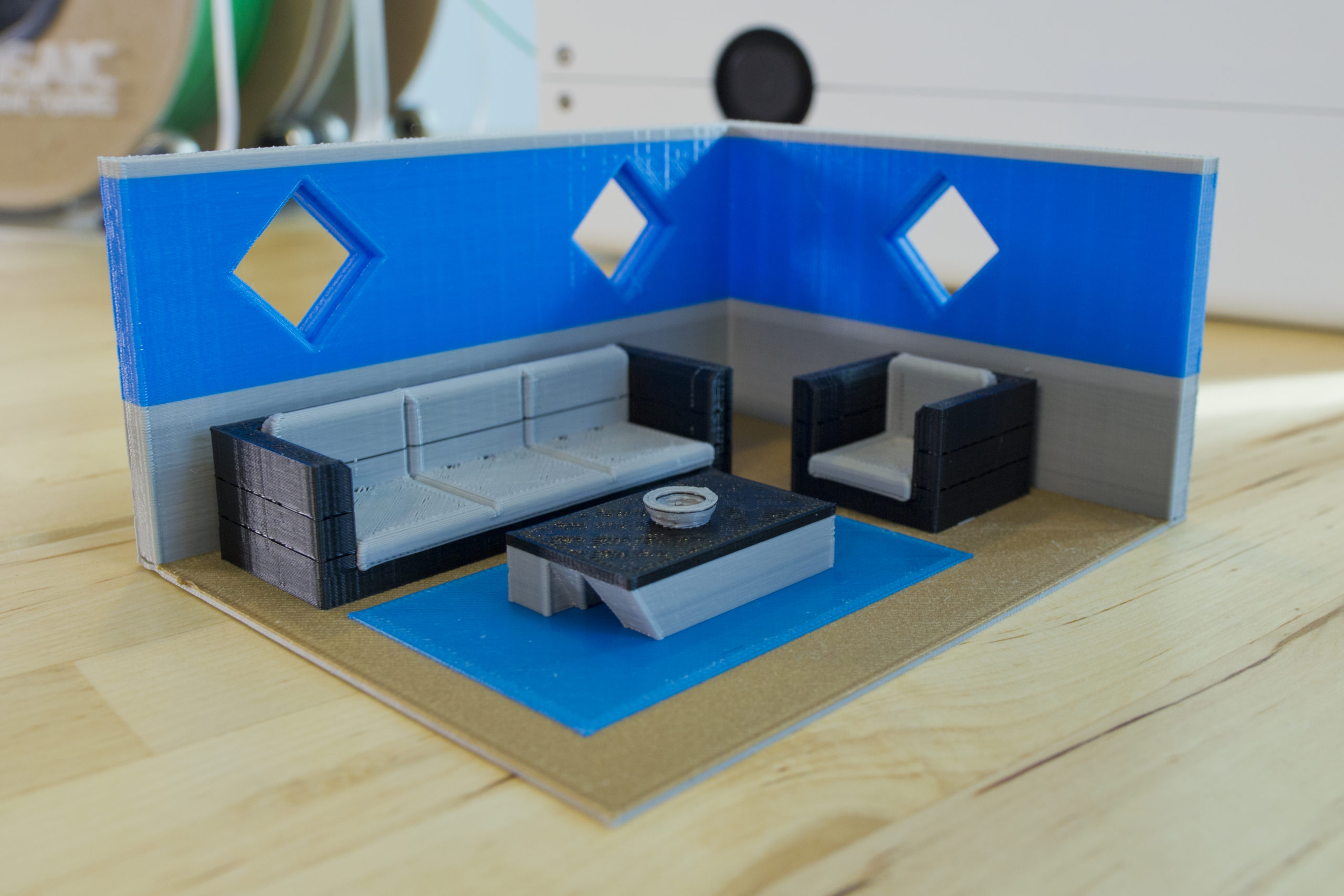

To enhance its reputation as a solution provider, LEONI Elocab created its intONE program, launched in January 2018. The program aims to offer customers turnkey solutions for any cable issue or problem they are experiencing. With intONE, LEONI Elocab will internalize the entire design process for its cables by providing customers with a 3D model of the cable design, selecting the appropriate connectors, choosing the appropriate cable route through the customer’s machine, and assembling the cable. Von Arx believes that intONE will benefit customers by allowing them to focus on other core aspects of their business (where they have their own competitive advantage) while LEONI Elocab utilizes its internal expertise to create the perfect cable.

LEONI Elocab currently exports approximately 90 percent of its products, primarily to the United States and Asia. However, von Arx expects the proportion of domestic sales to grow because the firm recently promoted a very talented Engineer to become its eighth sales representative to focus exclusively on the Canadian market, since the other sales representatives spend much of their time in the United States. He believes that LEONI Elocab is well situated for rapid growth in the near future because of the firm’s product offerings and the current word-wide megatrends. For example, one of the firm’s American customers purchases cables for equipment that is used to monitor sewer systems. The majority of American sewer systems were constructed in the 1940s and 1950s, which means they require constant monitoring as they become outdated. Additionally, the aging baby boomer generation will mean an increased need for the cables used in healthcare diagnostics. Finally, cable demand will also increase in response to the Industry 4.0 revolution that focuses on digitization and data collection, which will result in an unprecedented increase of demand for computer chips resulting in a higher demand for high-spec semiconductor cable solutions.

From 2001 to 2019, LEONI Elocab has grown from 12 workers to 100. This growth would not have been possible without the high retention rate at LEONI Elocab, as highlighted by some of the original employees from 1996 still working at the firm. Approximately one-third of the company’s employees manufacture cables, one-third perform cable assembly, and the remaining third is comprised of engineers and office staff. All three divisions of the company are essential to providing customers with turnkey solutions. The engineering staff was recently doubled to increase the firm’s capacity to offer 3D cable designs resulting from an incredible demand for intONE solutions. The availability of qualified engineers in Kitchener is a huge advantage to LEONI Elocab, allowing the firm to choose individuals from the talent pool who share its core company values. To attract the appropriate talent, LEONI Elocab employs one or two interns at all times and gives them exciting tasks to perform so they will share their experience with classmates. Although finding machine operators is slightly more difficult, LEONI Elocab is able to attract motivated workers by sharing its philosophy of tackling every customer issue with a team-based approach to arrive at the most efficient solution.

To remain at the forefront of the industry and maintain its reputation as a solution provider, LEONI Elocab invests annually in research and development (R&D) projects. These R&D projects focus on new materials that can be used to construct cables, innovative developments to improve the cable manufacturing process, and new technology that can be utilized to improve existing customer products. These internal projects, in addition to new customer requests, increase the firm’s manufacturing capabilities year after year. When LEONI Elocab develops a solution for a customer in a particular industry, it approaches other firms in that industry to spread awareness that a solution exists if they are having a similar issue. The cyclicality and fluidity that accompany involvement in the infrastructure and semiconductor industry represent the only challenge (albeit a minor one) that LEONI Elocab currently faces. However, the firm’s involvement in the healthcare industry stabilizes this fluidity because products within that industry are a necessity, and expenses are planned out well in advance.

Moving forward, LEONI Elocab plans to invest the $1.5 million it received from the Southwestern Ontario Development Fund into new technology and R&D. Additionally, the firm will continue to grow its local network by maintaining its involvement with the Waterloo Region Economic Development Corporation and the Ontario Chamber of Commerce. LEONI Elocab is also in the midst of a $14 million facility expansion, which is expected to add a minimum of 25 jobs. The layout of the new building includes an exercise room, cafeteria, and clean room to be used for manufacturing cables that are expected to meet stringent cleanliness guidelines. Von Arx believes the new facility’s modern design and open office concept will assist in filling these new positions and attracting younger talent for years to come.

For more information about LEONI Elocab Ltd, visit their website.

Published: July 22, 2019

Mosaic Manufacturing

Mosaic Manufacturing revolutionized the world of desktop 3D printers with the "Palette", an accessory for 3D printers that enables them to create multi-colour and multi-filament objects.

London Mat Industries

London Mat Industries Ltd (London Mat) is the manufacturer of the world famous “MATEX” Treadle Switches, used on Buses, Trains and Trams for door safety, opening and passenger counting.

Angstrom Engineering

Angstrom Engineering Inc. is a leading manufacturer of thin film vacuum deposition equipment and vacuum chambers equipment. The firm specializes in designing, manufacturing, selling and servicing machines that deposit thin films, (growing layers of materials on a substrate with thicknesses that can range from less than one nanometer to several microns).

Dura-Line

Dura-Line has is a manufacturer and worldwide distributor of communication and energy infrastructure products and systems.

DAVWIRE: Defense & Aviation Wiring

Defense & Aviation Wiring Inc. (Davwire) is one of Canada’s leading contract manufacturers in the electrical/electronic arena. The company specializes in wire harnesses, electrical panels and electrical assemblies used in aviation, defence, medical and rail industries.