News

Augmented reality

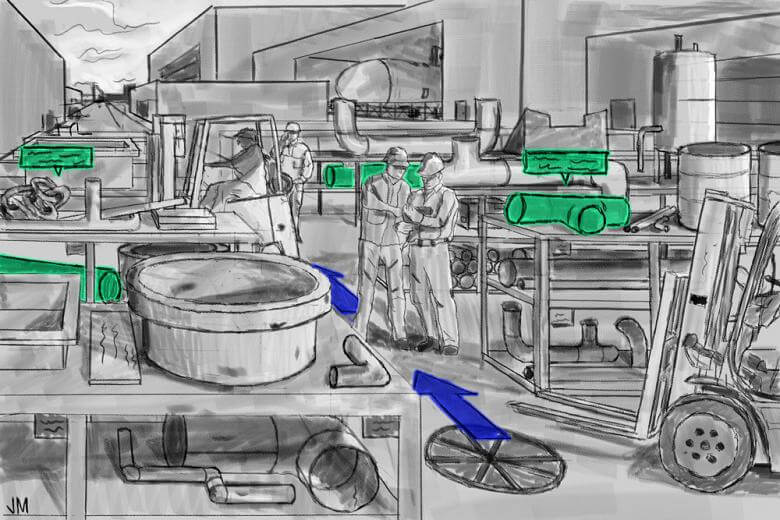

Augmented reality (AR) has recently emerged as a technology with the potential to greatly improve manufacturing processes. However, there is a common misconception that augmented reality and automation are competing technologies. The reality is these two technologies are complementary and can both be utilized to help firms improve productivity.

Augmented reality enables firms to utilize the Internet of Things, a key component of Industry 4.0, to gather information about the worker’s environment and provide it to the worker in real-time. Industry 4.0 refers to the creation of “smart” factories by collecting real-time data throughout the entire production process that can be used to make informed decisions. All of this data is stored in the Internet of Things, and is made available to employees with the implementation of AR technologies. This access to data elevates worker skill levels and makes the manufacturing company more efficient as a whole. Improving the skills of workers is essential for manufacturing companies planning to adopt automated production processes that allow simple tasks, such as consulting production manuals, to be eliminated, and enabling workers to perform more advanced and analytical tasks.

Ford, Boeing, Lockheed Martin, Porsche, and Mitsubishi Electric have all implemented some form of augmented reality to improve one aspect of their manufacturing process. The five aspects of manufacturing these brands have utilized augmented reality to improve are:

- Design

- Assembly

- Training

- Quality Assurance

- Maintenance

Design

Ford Motor Company utilized the Microsoft HoloLens AR headset to improve its design process. Ford’s design team uses this technology to overlay a physical prototype with potential designs of a car, or a car part, all in real scale. This enables designers to be more creative with their ideas and immediately make adjustments without having to build a new prototype. The technology also allows comments to be left in AR so colleagues can access the comments if needed. This enhanced level of communication results in designers improving their decision making, collaboration, as well as working more quickly and efficiently.

Assembly

The original wire assembly process at Boeing required employees to continuously consult a laptop to ensure that all wires were being correctly assembled. The assembly process drastically improved when Boeing implemented AR technology by utilizing headsets that provide employees with the same information directly in front of them. Employees can also issue voice commands that allow colleagues to join the headset’s video stream and assist with more complex assembly tasks. In addition to Boeing’s wire assembly process time being reduced by 25 percent, the AR technology helped to improve employee satisfaction and retention.

Training

Employee training benefits greatly from the implementation of AR technology. A prime example is the assembly process of Lockheed Martin’s F-35 aircraft. After providing employees with Microsoft HoloLens headsets, the assembly process time was reduced by 30 percent. The company’s engineers are able to view holographic images of an aircraft’s parts, as well as the assembly instructions, right in front of their eyes. The speed and quality with which Lockheed employees can complete their work has improved drastically, with engineering efficiency increasing to 96 percent.

Additionally, AR technologies are also being used by firms to train employees to work with robots and co-bots. Robots and co-bots are very advanced technologies, and without the help of AR training most employees are unable to efficiently work with the technologies, or capitalize on the full benefits being offered. The collection and presentation of real-time data to employees who are working with robots or co-bots allow them to better understand the technologies being used, which allows them to develop expertise working with the technologies at a much quicker pace.

Quality Assurance

Porsche is a company dedicated to being innovative and to providing customers with products of exceptional quality. In 2016, the company adopted AR technology for quality assurance at its manufacturing plant in Leipzig. The technology utilizes AR and the Internet of Things, allowing employees to use tablets to compare an already assembled car and its initial design before being sent to a customer. This innovative technology enables Porsche to save costs, save time, improve accuracy, and ultimately meet its high quality standards.

Maintenance

Mitsubishi Electric believes the most useful application of AR technology is the maintenance of manufacturing equipment. The company has been developing AR that allows employees to view a 3D model while they perform a service inspection of a facility’s manufacturing equipment. The technology will confirm the order of the inspection on an AR display, and employees will be able to enter inspection results with voice commands. This technology will remove the need for workers to constantly consult a maintenance manual, and make the maintenance process less time-consuming and less tiring.

The applications of AR technologies demonstrated by Ford, Boeing, Lockheed Martin, Porsche, and Mitsubishi Electric highlight the benefits that result from successful implementation of the technology. All of the previous examples demonstrate how AR technologies add value to the Internet of Things by providing the relevant information being stored to employees in a consumable manner. Additionally, it is clear that all of the benefits will not be negatively impacted by the adoption of more automated manufacturing processes. Forward-looking manufacturing firms that strive to be innovative and efficient, and are looking to embrace Industry 4.0, should consider the possibility of adopting both AR and automation technologies.

Works Cited

“How Brands like Boeing Use Augmented Reality in Manufacturing.” Intellectsoft. 29, Mar. 2018. https://www.intellectsoft.net/blog/how-brands-use-augmented-reality-in-manufacturing

Giffi, Crag, Michelle Drew Rodriguez, Bharath Gangula, Joann Michalik, Tomas Diaz de la Rubia, Jeffrey Carbeck, Mark J. Cotteleer. “Advanced Technologies Initiative: Manufacturing and Innovation.” Deloitte. 2015. https://www2.deloitte.com/content/dam/Deloitte/us/Documents/manufacturing/us-indprod-deloitte-and-council-on-competitiveness-advanced-tech-report.pdf

Ritesh. “Home Automation With Augmented Reality.” Augmented Startups. 16, May 2017. http://www.arduinostartups.com/augmented-reality-with-internet-of-things/

Prakash, Abishur. “Augmented Reality, Virtual Reality Converge With Robotics.” Robotics Business Review. 12, Mar 2018. https://www.roboticsbusinessreview.com/ai/augmented-reality-vr-converge-robotics/

Wright, Ian. “What Can Augmented Reality Really Do for Manufacturing?” Engineering.com. 11, May 2017. https://www.engineering.com/AdvancedManufacturing/ArticleID/14904/What-Can-Augmented-Reality-Do-for-Manufacturing.aspx