Ontario’s skilled and talented workforce provides the province’s manufacturers with an important competitive advantage. Like other sectors, however, Ontario’s manufacturers face headwinds related to recruitment, retention, and workforce development. While some of these challenges are related to COVID, other factors, such as demographics, rising costs of living, and tight labour markets loom large.

Programs and initiatives that support education, training, and workforce development are vital to the future competitiveness of manufacturing in Ontario. It is therefore critically important that these programs are aligned with the needs of manufacturers, which differ considerably from industry to industry.

This bulletin draws upon customized data from Statistics Canada to illustrate how the occupational composition of specific manufacturing industries differs. The insight provided in this bulletin can help stakeholders understand the workforce needs of manufacturers so that they can design and develop education, training, and development programs that are tailored to their specific needs.

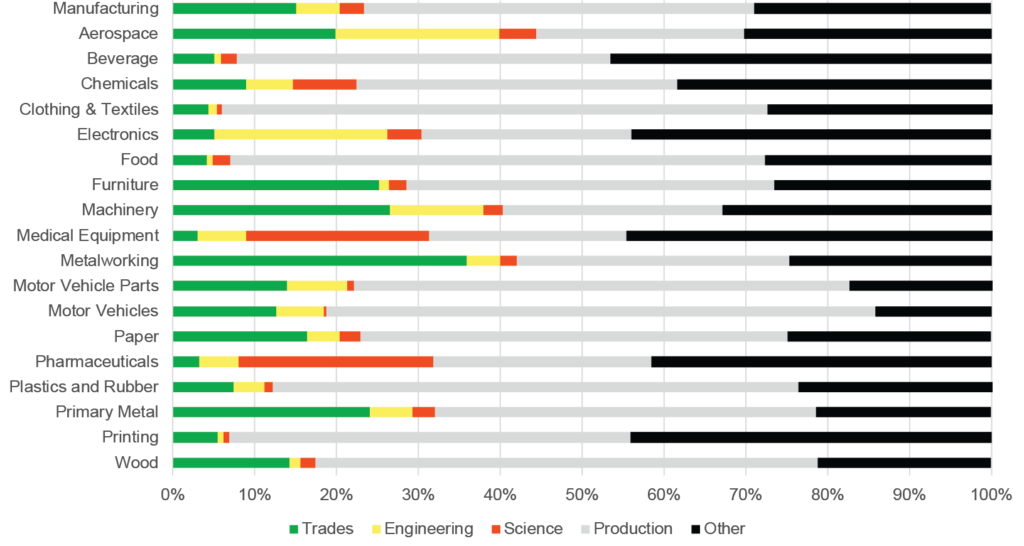

The figure below illustrates the occupational composition of 18 manufacturing industries and of the manufacturing sector as a whole. It includes five occupational categories:

- Trades, such as electricians, millwrights, machinists, and cabinetmakers.

- Engineering, including engineers and engineering technicians.

- Science, including chemists, biologists, and life science professionals.

- Production, including assemblers, material handlers, and machine operators.

- Other, including sales, administrative, clerical, regulatory, and supervisory occupations.

There has been a significant focus on encouraging younger persons to enter the trades. Much of this has happened in response to shortages of key occupations such as electricians, millwrights, and machinists. Initiatives to encourage people to enter the trades are especially valuable for employers in the metalworking, machinery, furniture, and primary metal industries.

The challenges of employers in other industries, however, are not exclusively related to the trades. Electronics and aerospace manufacturers rely extensively on engineers, while pharmaceutical manufacturers depend on chemists and biologists. Motor vehicle manufacturers and food processors rely on a more production-oriented workforce. Those in the fast-growing beverage manufacturing industry, which includes craft breweries and wineries, employ a substantial Number of sales and hospitality-related staff.

Pharmaceutical, aerospace, motor vehicle, metalworking, furniture, food, beverage, and machinery manufacturers all contribute significantly to Ontario’s economic and societal well-being. However, these data show that their workforce needs are diverse and distinct. Unlike machine builders, pharmaceutical product manufacturers are less concerned about millwrights and more concerned about chemists. Engineers are more important to electronics and aerospace manufacturers than to employers in most other industries, while production workers are top of mind for automotive manufacturers or food processors.

Three important takeaways:

- Different industries have different workforce needs. Some depend much more than others on STEM occupations. These industries will require education, training, and workforce development programs that recognize and align with their needs.

- The occupational composition of an industry is related to age, gender, and racial diversity. For example, a recent Trillium Network report demonstrated that progress on gender diversity made by certain pharmaceutical and beverage manufacturers had much to do with the fact that they relied on occupations that were not traditionally male-dominated. Conversely, industries that rely heavily on trades, which in Ontario are overwhelmingly male-dominated, will face ongoing challenges related to gender diversity if education, training, and workforce development practices do not change.

- Industries, occupations, and the workforce are all dynamic. It will be important to monitor the evolution of these data as manufacturers adopt new technologies and as governments and other stakeholders develop new education, training, and workforce development strategies.