-

Headquarters -

103 Richmond Street E, Unit 404, Toronto, Ontario, M5C 1C9

-

Year established -

2014

-

NAICS -

323120 - Support activities for printing

-

Major expansions -

2015

-

Employees -

15

-

Exports -

US, EU, Asia-Pacific

-

Download -

Mosaic Manufacturing

Mosaic Manufacturing revolutionized the world of desktop 3D printers with the "Palette", an accessory for 3D printers that enables them to create multi-colour and multi-filament objects.

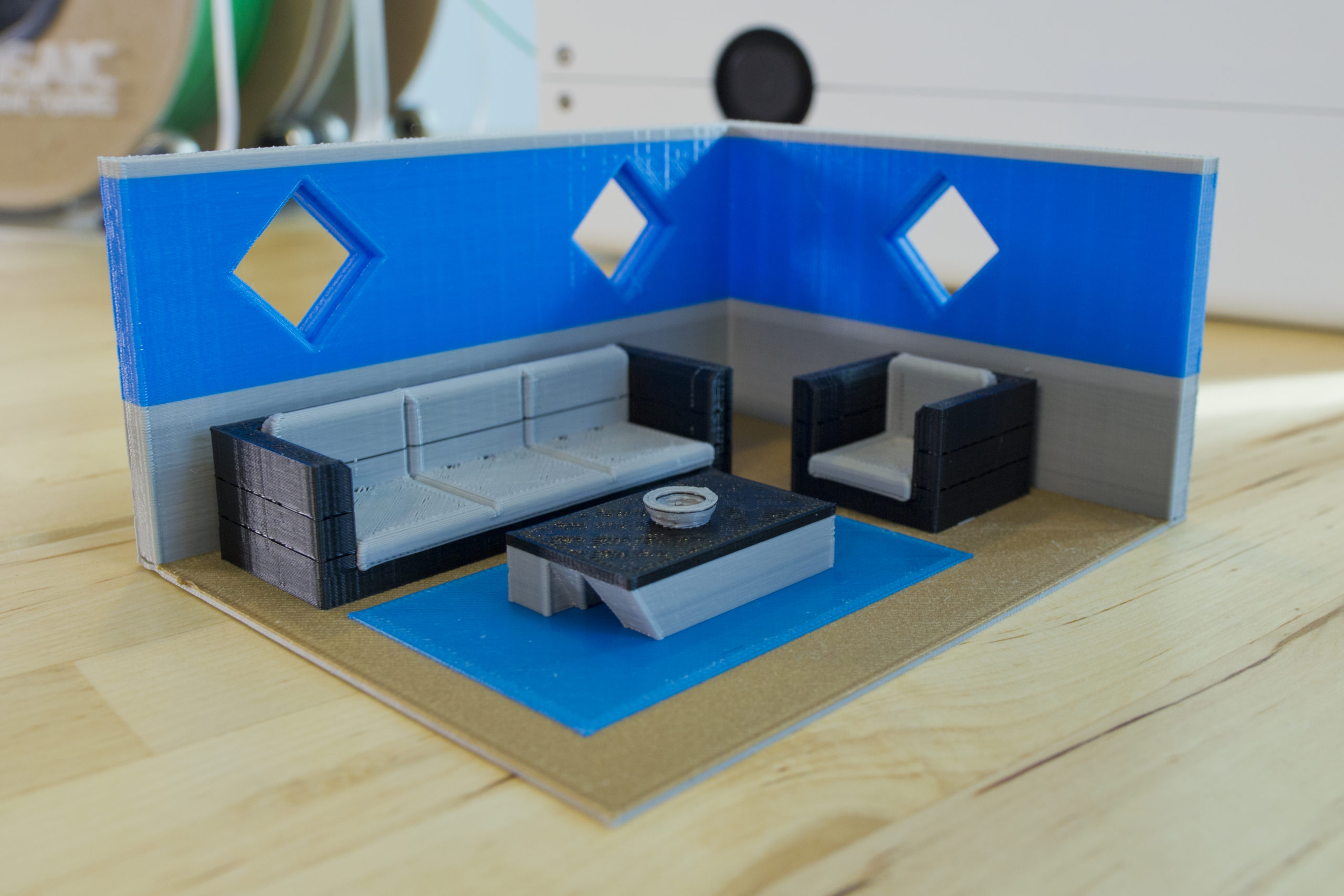

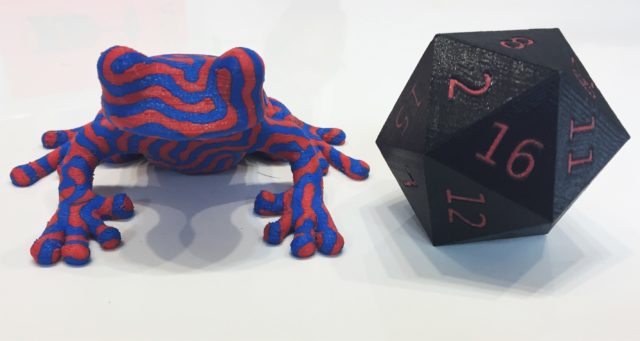

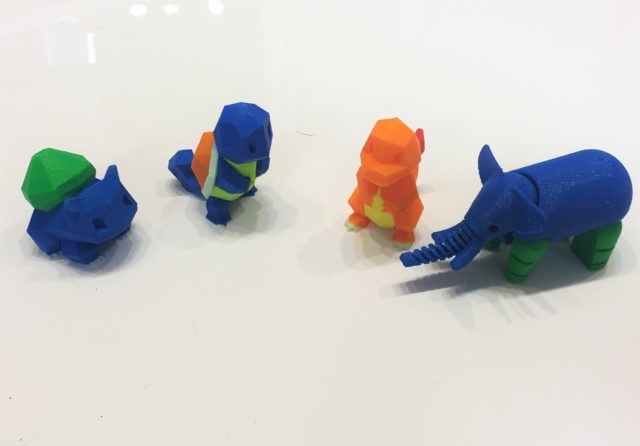

Pencil holders, name tags, figurines, or toys—they can all be custom designed and made in the comfort of your own home, thanks to the revolutionary technology of desktop 3D printers. Mosaic Manufacturing (Mosaic) has revolutionized the world of desktop 3D printers even further with its incredible printer accessory, the Palette.

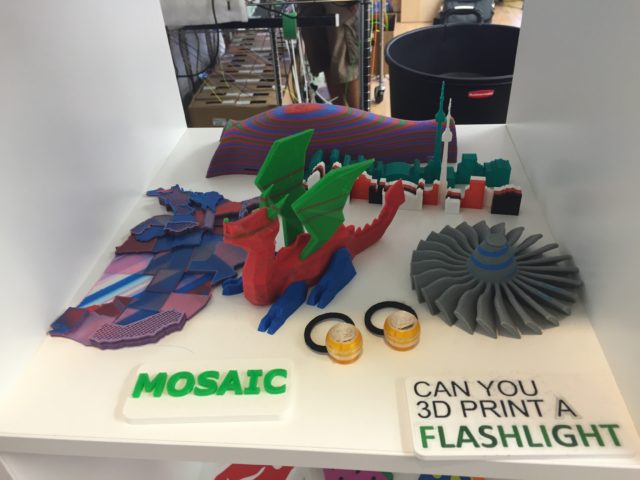

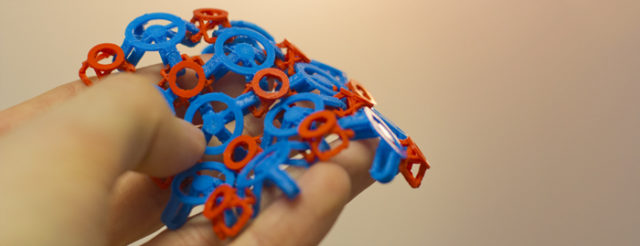

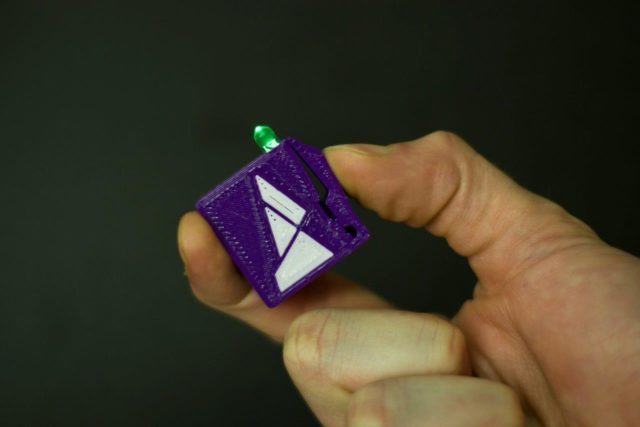

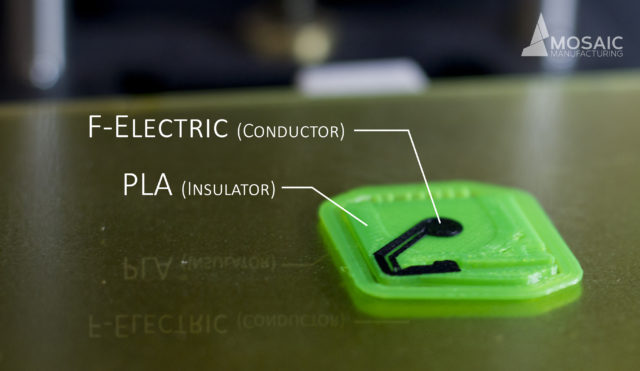

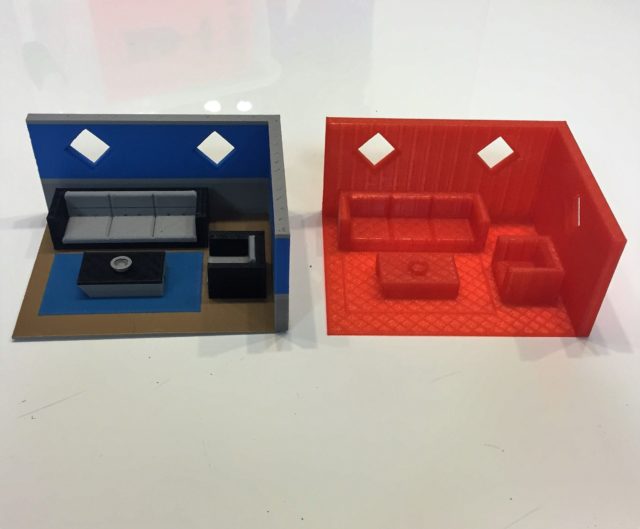

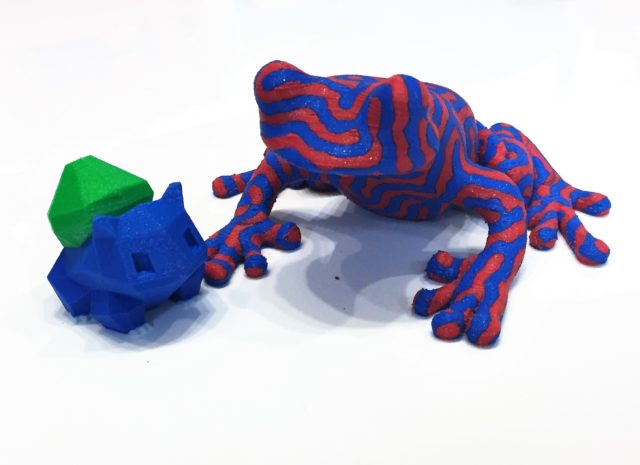

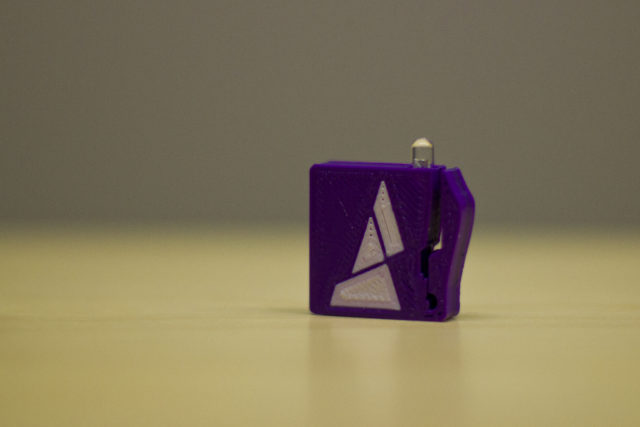

Desktop 3D printers create objects by melting down and reforming filament. Previously, although there were numerous filament types of varying colours and materials available on the market, the final object printed could only be made from one type of filament, of one colour. However, Mosaic’s Palette enables existing printers to print objects with up to four different filaments. The Palette brings life and variety to the monotone world of desktop 3D printing, as it is compatible with most desktop 3D printers (specifically, FDM 3D printers that use 1.75mm filaments). With the capability to use any filament, whether it be conductive, magnetic, or thermochromatic, the Palette allows users to create objects that are more dynamic, useful, and aesthetically appealing.

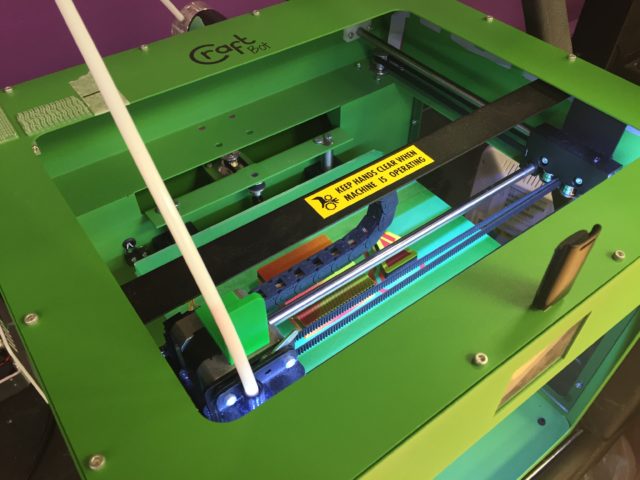

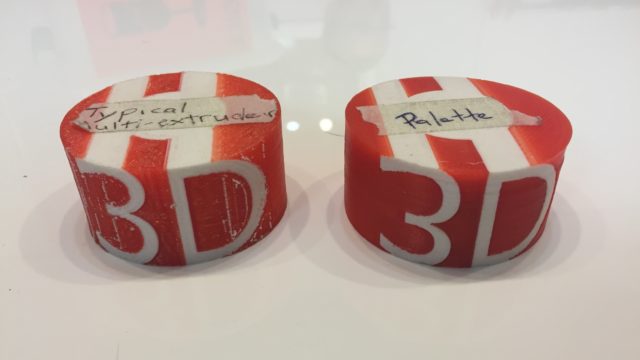

Mosaic’s competitive advantage comes from the fact that the Palette is easy to install/use, affordable, and offers exceptional results. The company is the only one to focus solely on multi-filament printing. Other manufacturers capable of multi-filament printing use multi-extrusion models. This means these printers have a separate extruder (tube through which the filament is melted and fed to the object) for each filament. Manufacturers of dual-extrusion or multi-extrusion systems are typically 3D printer manufacturers who dedicate a portion of their development to multi-extrusion technology. Mosaic is not seeking to integrate into building 3D printers; instead they work with existing printers on the market. This niche focus has allowed the company to create the complex system that makes multi-coloured 3D printing possible for desktop printers.

Before Mosaic introduced the Palette, consumers had limited options to print objects with multiple filaments. One option was to use printers with multiple extruders, with each extruder feeding a different filament. However, this technology had many drawbacks. As one extruder stopped and the next began, the initial extruder would often drip, creating spots and blemishes on the final multi-coloured object. Additionally, the multiple extruders require more wiring and space, resulting in a much bulkier and more cumbersome printer. The arrival of the Palette resolved these concerns.

Mosaic began in the summer of 2014, when three recent graduates of Queen’s University teamed up at the Queen’s Innovation Centre’s Summer Initiative program (QICSI). Mitch DeBora, a mechanical and materials engineer, had run a 3D printing business at the university while he was a student there. During this time, he often found that his customers would request that objects to be printed in multiple colours, but desktop 3D printers at the time did not allow for this. Derek Vogt, a mechanical and mechatronics engineer, and DeBora worked together on designing a method to enable a printer to print in multiple colours. Chris Labelle (a commerce graduate) completed the team that then worked to create and perfect a semi-universal printer accessory that enabled multi-filament printing.

The three young men shared an ambition to start a full-time company of their own with their diverse skill sets and mutual interests. At the end of QICSI, the trio won the pitch competition and the $40,000 prize. Soon after, the Palette was created and Mosaic Manufacturing was founded in July 2014. By November of that same year, DeBora, Vogt, and Labelle received their first mention in the press, and soon the company was very well known in the 3D printing community. In February 2015, Mosaic relocated from Kingston to Montreal to work with FounderFuel, an accelerator there.

In April 2015, Mosaic launched a wildly successful Kickstarter campaign to raise funds to develop the Palette and their company. Hundreds of people were eagerly awaiting the launch of the Palette into the market, and Mosiac met its goal within the first five hours of the campaign. The early bird portion of the sale alone made $5,000 to $7,000, and by the end of the campaign, Mosaic’s founders had raised 300 per cent of their goal.

The Palettes were set to be delivered by the end of 2015; however, Mosaic ran into several problems after the first trial shipment. Due to some issues with quality control and manufacturing, DeBora, Vogt, and Labelle elected to delay all deliveries of the Palette. When describing Mosaic’s goals for customer satisfaction, Labelle emphasizes the difference between “delivering a product versus delivering a product people love.” By that time, the Mosaic team had grown to encompass 13 employees (primarily mechanical, mechatronic, robotic, software, and firmware engineers), and the entire staff worked on altering and fixing the product. Now, the first batch of Palettes is scheduled to be shipped by the end of August 2016.

Mosaic’s business model centres on customer satisfaction and meeting consumers’ needs. The company always consults the close-knit community of 3D printer owners and enthusiasts to discover what new feature should be included in its products. The executive team often attends Maker Faires in the industry, not only to expand Mosaic’s customer base, but to interact with consumers and hear their concerns as well. Through this interaction with 3D desktop printer owners, the firm can constantly make useful and attractive changes to its product. The majority of Mosaic’s customers (60 to 65 per cent) are in the United States, along with a few distributors in Europe and Asia.

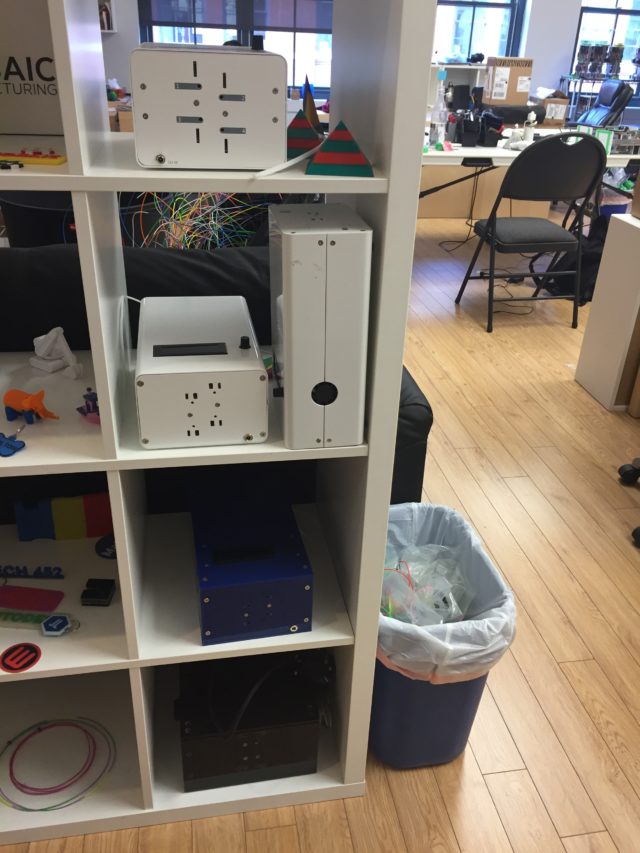

The Palette is manufactured at Mosaic’s main facility in Toronto. Some parts are sourced from China, after which, assembly, testing, and quality control are all conducted in Toronto. Opening a manufacturing facility near the city’s financial district was a unique strategic move. Mosaic’s founders specifically chose the Richmond Street office in order to have access to the young, innovative, and ambitious talent pool in Toronto. With all of the current team members based in the area, this location offers short commutes, and facilitates better communication and teamwork overall.

Thanks to an innovative product and government assistance programs (such as the Industrial Research Assistance Program (IRAP) and the Scientific Research and Experimental Development Tax Incentive (SR&ED)), Mosaic is expected to maintain its incredible growth in the coming years. The team plans to expand to a staff of 15 by September 2016, and will likely incorporate customer service and graphic design teams following the first round of shipments of the Palette.

Two years ago, Labelle, DeBora, and Vogt decided to make their dream of starting their own company a reality. Today Mosaic Manufacturing is at the forefront of the cutting-edge world of 3D desktop printing. The multi-coloured and multi-functional objects that the Palette will help to print are sure to inspire others in the future.

For more information about Mosaic Manufacturing, visit their website.

Published: August 22, 2016

LEONI Elocab Ltd

Located in Kitchener, Ontario, LEONI Elocab Limited is undergoing its second major expansion in less than a decade. The firm is the only Canadian division of LEONI Group, a global provider of products, solutions, and services for both energy and data management in various industries. LEONI Elocab offers a unique contribution to this global network by manufacturing customized cables and cable assemblies, providing a case-specific solution for every customer.

Angstrom Engineering

Angstrom Engineering Inc. is a leading manufacturer of thin film vacuum deposition equipment and vacuum chambers equipment. The firm specializes in designing, manufacturing, selling and servicing machines that deposit thin films, (growing layers of materials on a substrate with thicknesses that can range from less than one nanometer to several microns).

London Mat Industries

London Mat Industries Ltd (London Mat) is the manufacturer of the world famous “MATEX” Treadle Switches, used on Buses, Trains and Trams for door safety, opening and passenger counting.

FASTSIGNS of Windsor

FastSigns of Windsor offers full-service solutions in graphic design, signs, promotional products and custom solutions to fit every clients’ marketing needs.

Mosaic Manufacturing revolutionized the world of desktop 3D printers with the "Palette", an accessory for 3D printers that enables them to create multi-colour and multi-filament objects.