-

Headquarters -

75 Heroux Devtek Drive, Cambridge, Ontario, N3E 0A7

-

Year established -

1985

-

NAICS -

336410 - Aerospace product and parts manufacturing

-

Major expansions -

2015

-

Employees -

31

-

Exports -

N/A

-

Download -

Shimco

Located in Cambridge, ON, Shimco has served the aerospace, defense, space, industrial and other industries worldwide with precision manufactured parts, laminated and edgebond shims, tapers and spacers for over 25 years. Shimco offers a tradition of Innovation, Precision, and Execution, providing solutions that conform to exacting international and customer-specific standards.

“Shimco is committed to innovative product developments that will benefit customers in the aerospace industry, as well as those in the defence, space, and industrial markets” says president, chief executive officer, and owner of Shimco, Peter Voss.

This commitment has resulted in a tradition of innovation, precision, and execution, enabling Shimco to establish itself as the only company of its kind in Canada and one of only a very few aerospace shim manufacturers in the world.

Originally founded in Markham, Ontario in 1985, Shimco has served the aerospace, defence, space, industrial, and other segments worldwide with precision manufactured parts—such as laminated and edgebond shims, tapers, and spacers—for over 25 years. In December of 2015, Shimco relocated to its current facility in Cambridge, Ontario. Voss states that the move to Cambridge was a necessity due to exponential growth experienced year over year since his purchase of the company in 2011. Shimco quickly outgrew its Markham location thanks to its increasing number of contracts with tier-one suppliers and original equipment manufacturer (OEM) aerospace companies. Voss researched locations in the Greater Toronto Area, but Cambridge presented a larger and more cost-effective location that would allow Shimco to meet its future growth targets.

The 25,000-square-foot facility in Cambridge was built in July 2015, and is designed specifically for Shimco’s operations to enable maximum efficiency of workflow and product output. Equipped with numerous sophisticated VMX Hurco computer numerical controlled (CNC) milling machines, CNC lathes and a large 12-pallet, dual-horizontal CNC milling “Flexible ManufacturingHorizontal CNC System” made by Mazak, the focus of the new facility is on automation. Voss believes this focus will help Shimco to manufacture its products with greater precision and deliver higher-quality products consistently to its customers, as well as maximize output per shift without having to increase the number of floor employees. Voss’ philosophy of innovation has proven successful, as Shimco has tripled its sales while only increasing its workforce from 20 to 31 since his arrival in 2011.

Due to its well organized and automated work processes, Shimco can meet demand with only a single eight-hour shift daily. Voss sees this as a positive sign, stating that the facility will be able to support the aggressive growth targets he has set for the future. Although only one shift is needed at present, there are plans to build a second facility of equal size at the back of the Cambridge property in 2021. This building will be used to perform large- part surface treatment and testing, as well as light assembly operations. In 2019, Voss will bring small-part processing inside the current building envelope, which is currently outsourced. Voss notes that outsourcing these processes is very expensive, and the savings from performing surface treatment internally will pay for the installation of the processing capability inside the current building within a few years. Cost savings are welcomed by Shimco, but the motivating factor driving this decision is that OEMs and tier-one suppliers generally prefer to do business with vertically integrated suppliers. Therefore, having end-to-end control of all processes, including surface treatments, is needed to push Shimco past its current threshold and allow it to compete with larger companies for future contracts.

Shimco has collaborated with local educational facilities, such as the University of Waterloo, to create a “Centre of Excellence” in advanced manufacturing technology. This centre is used for research and development purposes dedicated to commercializing cutting-edge manufacturing and processing technologies. A Centre of Excellence already exists in Shimco’s Cambridge facility, and plans to expand that centre with the construction of the second Cambridge building in 2021 are in the pipeline. Discussions on dedicating the second floor of the future building to this purpose are ongoing between Shimco and its partners.

Shimco competes in a highly competitive industry comprised of 12 competitors, including itself. These 12 companies must compete fiercely for a small number of contracts from the few big customers that dominate the aerospace industry. Today, Shimco serves over 200 customers; however, a single customer, Bombardier Inc. (directly and indirectly through tier one suppliers) represents a sizable portion of its total sales. Voss says that until very recently, Shimco was securing only the smallest contracts (or “scraps”) outside of its traditional customers, but with its increased facility efficiency and continued product development, the company has begun contract talks with industry giants like Boeing and Airbus. Voss’ goal for Shimco is for it to become the preferred strategic partner of global aerospace, space, and defence OEMS and tier-one system integrators. To achieve this goal, Shimco must directly compete for these sought-after contracts in place of its usual smaller contracts.

Accordingly, Shimco is focused on differentiating itself from its competitors through the use innovative technology as well as superior customer service. As a smaller company (relative to its competitors), Shimco has always been more agile and responsive than larger firms when serving customers. The company can address any urgent customer needs since its facility is not currently running at full capacity, enabling Shimco to accept last-minute orders. Shimco is also quicker when it comes to addressing customer concerns because of its small team, which is dedicated to customer satisfaction in every aspect of each transaction.

Most importantly, Shimco is continuously developing new patented technology that is attracting the attention of larger customers in the industry. Through the research and experimentation conducted in its Centre of Excellence, Shimco is able to add value to some of its most basic and unassuming products, such as its shims; the company created “Smart Shims” capable of monitoring and wirelessly transmitting stress loads, temperature, pressure, pre-mature corrosion and delamination where they are placed, in real time. Through such innovations, Shimco is transforming itself from a typical manufacturer to a technology firm that also has traditional and advanced manufacturing capabilities, making it a truly unique company within the industry.

Shimco has instilled a company culture that aligns its company goals with its employees’ goals. For instance, bonuses are determined by the number of months that the employees meet their production quota as a singular group. Voss states that this method keeps employees on task and motivates them to use every minute of their shifts efficiently. The system effectively empowers Shimco’s employees by allowing them to control their bonuses and showing them how vital they are to operations. Voss encourages employees to meet their quotas every month, and has supplied the state-of-the-art facility with the tools necessary for his employees to succeed. The facility utilizes an organizational system that communicates the type and amount of work required of each employee each day in order to meet the month’s quota.

In all of these ways, from its company culture to its manufacturing processes, Shimco sets the standard for innovative OEMs of the 21st century to follow.

For more information about Shimco, visit their website.

Published: December 12, 2018

Solar Ship

Solar Ship is a manufacturer of hybrid aircraft. The primary goal of the company is to produce hybrid aircraft that are able to take off and land nearly anywhere to allow for the shipment of goods and emergency services to the most remote regions of the world.

Laval International

Located in Windsor, Ontario, Laval International (Laval) manufactures production-ready moulds and composite parts for a wide range of industries. In addition to manufacturing, Laval offers engineering and prototyping services to customers seeking turnkey solutions. International presence can be attributed to its commitment to providing customers with the most technologically advanced and effective products.

Angstrom Engineering

Angstrom Engineering Inc. is a leading manufacturer of thin film vacuum deposition equipment and vacuum chambers equipment. The firm specializes in designing, manufacturing, selling and servicing machines that deposit thin films, (growing layers of materials on a substrate with thicknesses that can range from less than one nanometer to several microns).

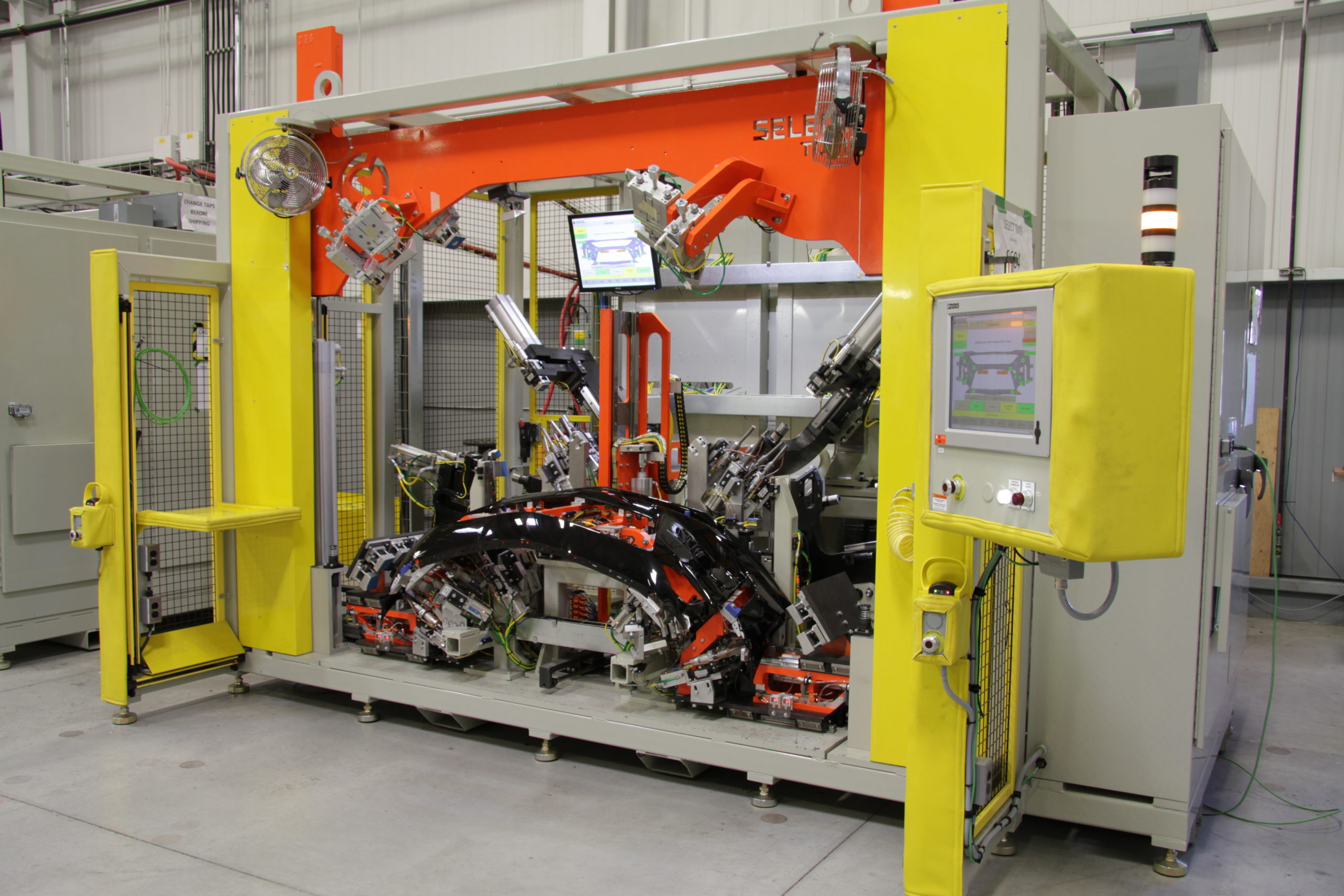

Select Tool Inc.

Select Tool is a manufacturer that has developed a reputation for providing high quality full-service gauges, fixtures, automation, and specialty tooling for the automotive, aerospace, and transportation industries.

BOS Innovations

BOS Innovations develops custom factory automation solutions to help companies reach greater levels of productivity and profitability. The company’s mission is to advance North American manufacturing through world class integration of automation systems with innovative engineering, build quality, and service.