-

Headquarters -

61 Rawson Ave, Barrie, Ontario, L4N 6E5

-

Year established -

1994

-

NAICS -

333990 - All other general-purpose machinery manufacturing

-

Major expansions -

2019

-

Employees -

85

-

Exports -

U.S., U.K., Mexico, Brazil, China, Thailand

-

Download -

Linear Transfer Automation

Based in Barrie, Ontario, Linear Transfer Automation is a global supplier of press transfer automation, blank feed systems, and press-to-press automation. Linear is able to customize its automation solutions to fit specific equipment geometry and requirements for customers.

Based out of Barrie, Ontario, Linear Transfer Automation Inc. (Linear) is a global supplier of press transfer automation, blank feed systems, and press to press automation. Linear is able to customize its automation solutions to fit specific equipment geometry and requirements for its customers, regardless of how old the equipment is or how the equipment is organized on the shop floor. Each system is built utilizing scalable and modular designs with in-house developed application optimization software to ensure that the servo-drive trains exceed any speed limitations in the stamping process, thus ensuring that Linear’s equipment is never the bottleneck. For large program launches, Linear can design and manufacture turnkey projects for its customers (“turnkey project” refers to the procurement of an entire stamping cell from one source, rather than combining individual pieces from multiple vendors). Customers value Linear’s technical, project management and financial capabilities to handle such large projects. Additionally, Linear’s multiple locations across the world offer 24/7 support for all its customers’ equipment. Approximately 90 per cent of the company’s sales are to the Automotive industry (including 5 of the world’s top 10 OEMs), but Linear also manufactures products for other industries, including outdoor power equipment; heating, ventilation, and air conditioning (HVAC); renewable energy, consumer goods; and appliances (including the world’s largest appliance manufacturers.

The company is very active in co-op programs at Georgian College, University of Guelph, and University of Waterloo, hiring more than 50 co-op students since 2009.

Linear was established in 1994, with new ownership (part of the Flodraulic Group) and management in place since 2009. Flodraulic Group, is one of the leading fluid power distributors in North America with more than 18 locations in the United States and Canada. Over time, Linear was able to expand its sales and service facilities in Mexico, Brazil, China, Thailand, and the United Kingdom. Due to new market penetration and customer development, Linear has experienced dramatic growth since 2009. As a result of this growth, Linear now employs almost 90 associates in the Americas, the majority of whom are engineers. Linear has an additional 18 associates in Asia. The company is very active in co-op programs at Georgian College, University of Guelph, and University of Waterloo, hiring more than 50 co-op students since 2009. Linear also has certified apprenticeship programs for millwrights and electricians since it employs a large number of associates involved in the trades as well.

Linear’s success can be largely attributed to its diverse capabilities and genuine concern for its customers. The company’s management realizes that every customer is different, and requires a unique transfer automation system to maximize productivity. About 50 per cent of Linear’s work is retrofitting old equipment, which allows customers to improve their productivity without purchasing complete new stamping cells. Linear’s ability to offer a technical solution to outdated equipment is one of the reasons that it was not significantly affected by the 2008 recession. The company capitalizes on its unique product offering by upgrading existing technology, as well as creating new products. This constant product development has helped Linear achieve growth in both automotive and non-automotive sales. The company is looking to add additional OEMs to its customer base in the near future. A large amount of Linear’s business is exports (primarily to the NAFTA region), which means that its major competitors are other global companies from United States and Europe.

Along with other manufacturing firms in Barrie, Linear believes strongly in showing continued support for the area’s manufacturing industry.

Linear prioritizes involvement within the local community. As noted, the firm is very active in the co-op program offered by Georgian College. Its employees are also leaders in the community at think tank and network sessions, where they share their insights and experiences with other manufacturing firms in Barrie. Many Linear employees volunteer their time to Simcoe Hospice, a charity in Barrie that strives to enhance the quality of life for those who have been affected by a life-limiting illness, and the firm supports the charity through company donations as well. Linear also sponsors a youth robotics program in an effort to motivate the younger generation to continue studying STEM subjects. Recently, the company participated in a training and technology exposition that was designed to market the manufacturing industry to local young people. Along with other manufacturing firms in Barrie, Linear believes strongly in showing continued support for the area’s manufacturing industry.

One of the major challenges that Linear must address is the attraction and retention of qualified employees. To overcome this difficulty, Linear has decided to hire new graduates and develop them within the company through employee training and development. Due to its involvement in multiple co-op programs, the firm believes it will be successful in hiring and retaining recent graduates. The strategy has been successful so far, with a 100 per cent retention rate of hired grads in 2013.

Another challenge for Linear is that OEMs and tier 1 customers are interested in purchasing products that incorporate Industry 4.0 technology, while others do not yet see the value proposition. On the one hand, Linear can easily address this challenge because it is able to customize all of its products; on the other hand, the firm wants all customers to realize the value that Industry 4.0 technology provides. Linear has experienced the benefits of this technology first-hand, after developing its own enterprise resource planning system that is integrated with its engineering system and eliminates the need to manually enter data. The company created this system internally when it could not discover any existing software that catered to its unique needs. Now, Linear is able to effectively use data analytics and make increasingly data-driven decisions. Management believes other small and medium-sized manufacturing firms can benefit from this software, and eventually plans to commercialize it.

Linear aims to keep expanding into new markets, build its customer base, and continue to integrate Industry 4.0 technology into its products. Recently, the firm demonstrated a system at a trade show that was able to present real-time data from a machine at its facility in Barrie. Linear has also developed the capability to store multiple programs in its database for easy retrieval and future use. Another upcoming development will focus on the incorporation of data analytics into Linear’s products, which allows for preventative maintenance and predictive failure. This development will help Linear continue its customer-centric approach to business by offering customers additional information that will translate into increased productivity. The firm is currently looking at building up its Controls and Service department in anticipation of the additional service it is preparing to offer.

Finally, Linear intends to maintain its involvement with government funding programs to further its research and development (R&D). It has had positive interactions with the government in the past through Canadian Manufacturers & Exporters (CME), Mentor Works, and the Automotive Supplier Competitiveness Improvement Program (ASCIP). There is no doubt that Linear’s focus on R&D and innovation will allow it to continue its rapid growth in the future.

For more information about Linear Transfer Automation, visit their website.

Published: October 3, 2018

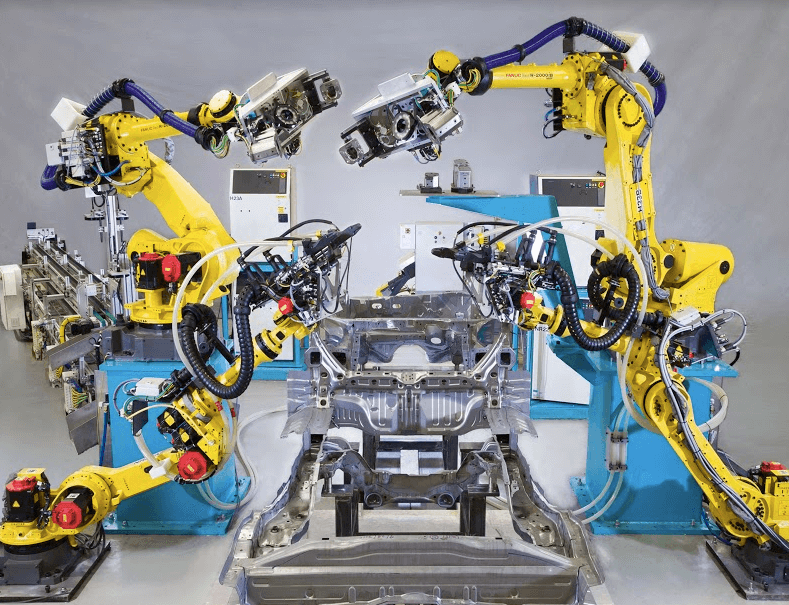

CenterLine

CenterLine is a manufacturer of custom automated welding and assembly lines, as well as resistance welding-related products. The firm is known worldwide as a leader in fastener welding technology, which is used in the production of automotive components.

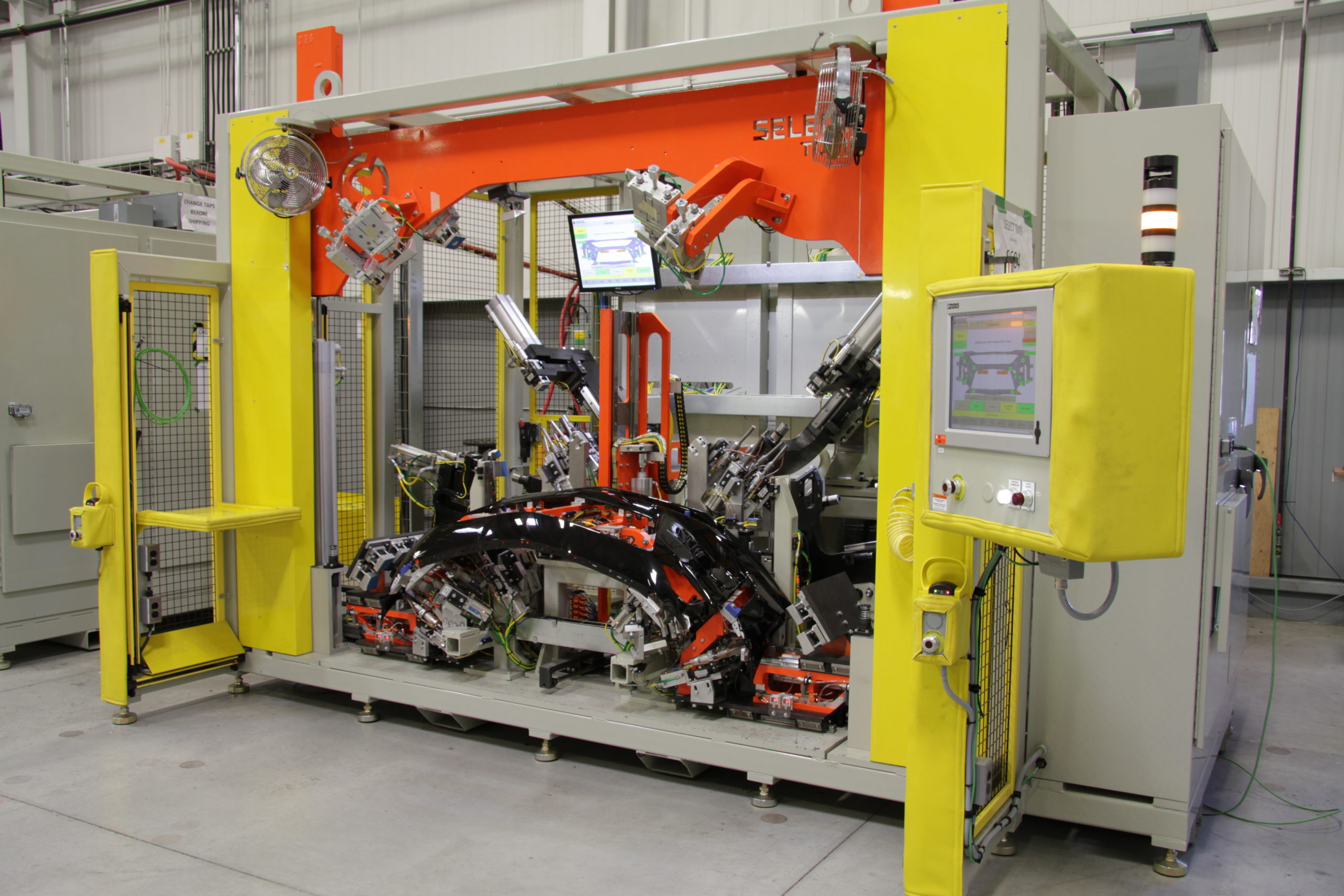

Select Tool Inc.

Select Tool is a manufacturer that has developed a reputation for providing high quality full-service gauges, fixtures, automation, and specialty tooling for the automotive, aerospace, and transportation industries.

Abuma Manufacturing Limited

Abuma Manufacturing Ltd (Abuma) is a Build-to-Print metal fabricator capable of manufacturing custom components. Abuma fabricates the metal components and upper-level assemblies and integrates additional outside services like surface coatings, electrical, pneumatics, and purchased equipment as required.

BOS Innovations

BOS Innovations develops custom factory automation solutions to help companies reach greater levels of productivity and profitability. The company’s mission is to advance North American manufacturing through world class integration of automation systems with innovative engineering, build quality, and service.

Innovative Automation

Located in Barrie, Ontario, Innovative Automation Inc. is one of the most creative manufacturers of custom automation solutions in North America. It is Innovative Automation’s Vision to “Be the first choice provider of automation solutions to global leaders in manufacturing”. To ensure that it is equipped to handle even the most complex machine solutions required by its customers, Innovative Automation has an electrical systems design team, a mechanical design team, a programming team, and a mechanical build team.