-

Headquarters -

26 Gagan Road, Spanish, Ontario, P0P 2A0

-

Year established -

1994

-

NAICS -

333130 - Mining and oil and gas field machinery manufacturing

-

Major expansions -

N/A

-

Employees -

24

-

Exports -

US, South America, Central America

-

Download -

J&S Manufacturing

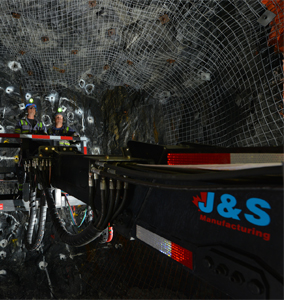

J&S Manufacturing is a mining equipment manufacturer, with in-house design capabilities that allow the firm to manufacture mobile equipment as well as technical custom equipment. The company’s motto is “Built to Perform”.

J&S Manufacturing (J&S) is a successful mining equipment manufacturer located in Spanish, Ontario. The company’s motto is “Built to Perform,” conveying the fact that all of its equipment is durable and dependable. J&S’s in-house design capabilities allow the company to manufacture mobile equipment as well as technical custom equipment, transforming customers’ ideas into usable solutions. The quality of the equipment manufactured, along with the company’s ability to customize products, has helped J&S to sell its equipment around the world.

Originally known as J&S Schmitz Overhauling and Manufacturing, the firm was founded in 1994 by Joe and Sylvie Schmitz. It offered a diverse product line comprised of mining equipment, barges, and bridges before being acquired by the Walden Group of companies in 2008. After this acquisition, the Walden Group changed the company’s name to J&S Manufacturing, and transitioned it into manufacturing high-quality mining equipment only. The acquisition allowed another firm within the Walden Group of companies, Walden Equipment, to be the sole distributer of J&S products. Since the introduction of its mining fleet, J&S has become well known in the global mining industry, and has grown substantially.

The products that J&S manufactures are designed specifically for the underground mining utility industry, which allows Walden Equipment to focus on distributing J&S products to companies who require service vehicles to transport material, do electrical work, or install ventilation systems. J&S is capable of manufacturing both stock and custom equipment, as well as individual machine parts. Equipment usually takes two to three weeks to manufacture, so the company always has multiple projects underway at the same time. J&S focuses on designing equipment that is easy for the end user to operate, and provides customers with the option to interchange parts across its entire product line. The company’s main goal is to enhance its customers’ productivity, so all of its equipment is manufactured with cost-effective maintenance or repairs in mind.

Approximately 70 percent of J&S’s sales occur in Canada and the United States through direct distribution to the customer by Walden Equipment. Outside of these two countries, J&S has established relationships with local distributors who are responsible for selling its products in their respective regions. The remaining 30 percent of sales are worldwide, but most of these exports go to Latin America. Although J&S has sold its equipment all over the world, it only sells to regions where it can service and perform maintenance on its equipment. Customers value this decision because it gives them confidence that if something happens to the equipment, J&S will be able to provide excellent customer support. In addition to this exceptional customer service, customers also value the firm’s ability to produce robust, reliable equipment that is easy to use.

J&S has 24 employees working as two teams: an equipment building team and a design team. Individuals hired to be part of the design team typically have an engineering background, and are comfortable working with various graphics programs. Employees on the equipment building team include mechanics, machinists, welders, and other skilled trades workers. The majority of employees commute to work from surrounding areas such as Elliot Lake, Blind River, and Sudbury.

Spanish, Ontario is a very small community, so J&S takes every opportunity to join with and support other local businesses and residents. The company sponsors fireworks, fairs, and other local initiatives when they occur. Moreover, J&S offers the community its expertise in working with large equipment by repairing equipment that belongs to local residents. Being part of a small community has also allowed J&S to develop a positive relationship with the municipal government, and capitalize on available government programs. In addition to utilizing various training programs funded by the government, and being a member of the Northern Ontario Business Association, J&S has enjoyed positive interactions with the Business Development Bank of Canada and the Excellence in Manufacturing Consortium. A program offered by Export Development Canada also helped J&S with its expansion into Mexico.

Like many manufacturing firms, the greatest challenge that J&S faces is attracting and retaining skilled trades workers. The company has a limited pool of talent to choose from because of its northern location. However, due to previous markets in the area, there are many local hardworking individuals with forestry experience. Capitalizing on the training grants offered by the government has helped J&S retrain these individuals to become productive employees at J&S. Further, the company believes it will benefit from the global manufacturing hub that is being developed in Sudbury by gaining the opportunity to hire experienced workers from the area. The apprenticeship program at Cambrian College also provides J&S with the opportunity to develop relationships with young and talented individuals, making them more likely to return for work. J&S is addressing the issue of retaining employees by offering competitive wages, organizing various company activities, and providing pension plans.

Another upcoming challenge for J&S will be to address the electrically powered equipment trend within the mining industry. Mining companies are travelling farther down into mines than ever before, and utilizing batteries to power equipment is often perceived as the more efficient and safe method. Developing electrically powered equipment carries a great deal of risk because there are no proven results for using this equipment, and the research and development (R&D) costs required to test this innovative technology are significant (considering there is no guaranteed return on investment). Additionally, the value of mining equipment is directly related to the price of the commodity being collected, which leads to drastic fluctuations in the market. This volatility can cause cash flow issues for companies that manufacture mining equipment, adding another layer of risk to investing in the development of electrically powered equipment. Before investing in this type of R&D, J&S plans to carefully monitor the market and its competitors to determine if the investment is worth the risk, and if so, the optimal method to beginning developing these electric products.

In the short term, J&S plans to continue growing by expanding into more foreign markets where it can service and perform maintenance on its equipment. Doing so will help the company to further diversify the regions in which its products are sold, which will alleviate some of the risk faced by J&S when local markets fluctuate. Selling products to regions that are not connected or related to one another will also allow J&S to maintain a steadier cash flow. Over the long term, J&S hopes to implement a stronger R&D initiative to stay at the forefront of the industry (e.g., remotely controlled equipment represents one growing trend that the company would like to investigate). This heightened focus on new trends and R&D will ensure that J&S keeps developing its reputation as an innovative manufacturer that provides high-quality mining equipment.

For more information about J&S Manufacturing, visit their website.

Published: August 28, 2018

Parmerit Inc. | Wolfe Heavy Equipment

When selecting a product or service, manufacturing customers look for companies that can deliver high quality and expertise. Parmerit Inc. (Parmerit) and Wolfe Heavy Equipment (Wolfe), two manufacturing companies located in Strathroy, Ontario, are companies that clearly understand the needs of their customers. Not only do they offer technical expertise, they also have an ability to manage projects and products tailored to their customers’ specific needs.

Industrial Parts Manufacturing

Industrial Parts Manufacturing specializes in CNC machining, general machining, welding and fabricating.

Heat Design Equipment

Heat Design Equipment manufactures infrared heaters for asphalt construction and repair using patented, state of the art technologies.

Timberland Equipment

Timberland Equipment is a global leader in the integrated design, manufacture and support of engineered winches, hoists, sheaves, derricks and tensioning equipment for the world’s most challenging infrastructure and capital equipment projects.

CMI Heavy Industries

CMI Heavy Industries is a leading provider of heavy fabricated, forged and cast machined components and assemblies.