-

Headquarters -

2 Prospect Road, Morrisburg, Ontario K0C 1X0

-

Year established -

1969

-

NAICS -

339110 - Medical equipment and supplies manufacturing

-

Major expansions -

1990, 2015

-

Employees -

60

-

Exports -

Europe (primarily)

-

Download -

Tri Hawk Inc.

Xenopus is the manufacturing arm of Tri Hawk, a manufacturer and supplier of high-quality dental burs. Originally started as an importer of European burs, the firm has developed strong production capabilities and has pushed itself to the forefront of global production of high-quality products. Though the business is subject to extensive and costly regulatory licensing to sell internationally, Tri Hawk is finding success through growing its export base.

Xenopus Inc. (Xenopus) is the manufacturing arm of Tri Hawk Inc. (Tri Hawk), a manufacturer and supplier of high-quality dental burs (the drill bits used in dental procedures). Celebrating its 50th year of operations in 2019, Tri Hawk has seen strong domestic and international growth, and continues to pursue its goal to be recognized as the global gold standard in dental burs.

Tri Hawk was founded in 1969 by its current chief executive officer, Gustel Fischer—originally to import high-quality European dental burs for distribution in the Canadian market. In 1986, Tri Hawk management decided that the firm should produce these burs itself, and thus, Xenopus was established. Tri Hawk quickly outgrew its first production facility in Cornwall, Ontario and moved to a larger one in Morrisburg, Ontario. Over the past 30 years, the Morrisburg facility has expanded several times to meet rising demand.

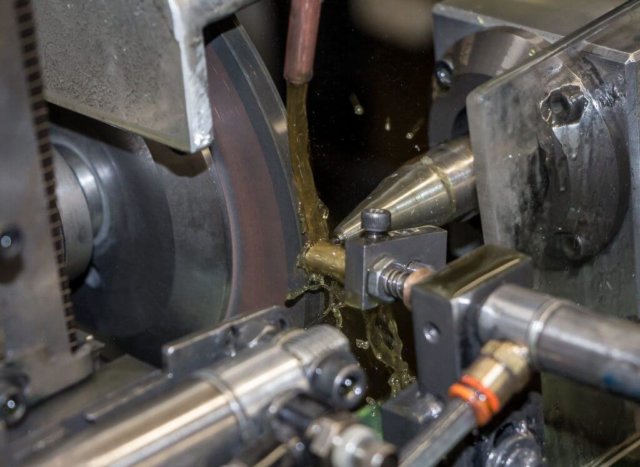

Tri Hawk focuses solely on manufacturing and selling top-quality dental burs. Xenopus’ stringent quality control and innovative designs allow Tri Hawk burs to outperform the competition in terms of reliability, strength, and cutting speed. These bur designs are made possible because Xenopus creates and builds its own fluting machines. Other bur manufacturers purchase standardized equipment and make small modifications, whereas Xenopus builds and designs machines from scratch. Recently Xenopus has built a custom 6-axis fluting machine that will provide additional product flexibility and allow the business to retain its competitive advantage amidst a continually changing industry.

Production has increased threefold over the past five years, driven by a surge in demand for Tri Hawk’s products. Production runs 24 hours a day, five days a week, with ‘lights-out’ production occurring at night. ‘Lights-out’ production refers to an automated, unstaffed shift that typically runs without directing resources to human necessities such as lighting. A recent facility expansion has allowed Xenopus to expand its production capacity by at least 40 percent. This will ensure that Tri Hawk can continue to scale up production and meet the ever-increasing demand for its products, without additional major investment.

Tri Hawk employs approximately 60 people, most of whom work in production occupations. Over the past 15 years, the firm has prioritized employees with advanced technical skills that foster innovation and improve efficiency. Tri Hawk generally seeks innovative individuals that have technical skills that can be developed into advanced Industry 4.0 techniques, such as predictive maintenance. However, in addition to a general shortage of qualified candidates, Tri Hawk has found that it is difficult to convince young workers to move from the urban Ottawa area to rural Morrisburg. It can take up to a year to fully train a new employee, so management must be particularly selective in choosing candidates who will be with the firm for at least several years.

Tri Hawk recognizes that not all dentists are interested in using premium burs, and thus promotes its products as being “built for the bur connoisseur.” The company focuses its advertising by attending dental trade shows across the world, running targeted ads in dental magazines, and seeking out dental professionals that place an emphasis on premium products. Tri Hawk’s imagery is designed to stand out and promote its products as high-class, featuring a powerful black and yellow colour scheme and pictures of violins and cellos with burs in place of bows.

Tri Hawk has an international presence, and exports to over 80 countries. In the past decade, its annual sales in Europe have grown ninefold, from approximately $290,000 to $2.6 million. Today, exports account for over 80 percent of the Tri Hawk’s total sales, and 70 percent of these exports go to Europe. This expansion is fuelled by international trade shows and five satellite sales offices located in New York, Luxembourg, Brazil, and India. This diverse export base creates a business environment that is generally recession-protected, as a downturn in one area is often offset by an upturn in another.

Fischer views exports as incredibly important to Canada’s economy, and believes that more can be done by the Canadian government to support small business exports. Specifically, he argues that providing funding for attending international trade shows would encourage small businesses to expand into international markets. Displaying at trade shows can be vital for generating international sales, but it can also be cost-prohibitive for a small organization. Funding in this regard would help to offset the high certification costs required to sell internationally.

As a supplier of medical equipment, Tri Hawk is subject to a highly regulated business environment. When the firm was first created, it faced little government oversight. Regulatory compliance became prominent in 2002 when the European Union classified dental burs as a Class II medical device, thus requiring official quality verification systems. In 2003, Canada established a similar quality verification system, the Canadian Medical Devices Conformity Assessment System (CMDCAS). Since then, regulatory licensing has cost Tri Hawk tens of thousands of dollars per year.

In 2016, Canada altered its licensing framework to meet the Medical Device Single Audit Program (MDSAP), a multinational auditing organization that satisfies requirements from the relevant regulatory agencies in Australia, Brazil, Japan, and the United States. Though this arrangement allows for less reporting should a business wish to export to more than one of these countries, it adds thousands of dollars to the licensing fees. The cost of certification is negligible for large multinational companies, but can be extremely constraining for small businesses like Tri Hawk.

Tri Hawk has formed beneficial partnerships with external organizations. The firm works extensively with local colleges, including Algonquin College and St. Lawrence College, to develop and build machinery and equipment. In addition, Tri Hawk is a member of various U.S. and Canadian dental and manufacturing organizations, which help the business navigate technically difficult regulations and lobby governments. The company regularly sponsors charitable organizations, having provided over $250,000 in money and equipment to date.

With its recent growth, expansion into global markets, and strong track record of success, Tri Hawk is on track to be recognized as one of the world’s leading manufacturers of high-quality dental burs. The firm’s continuous innovation and commitment to quality is sure to keep both dentists and their patients smiling.

For more information about Tri Hawk Inc., visit their website.

Published: November 11, 2019

Sciencetech

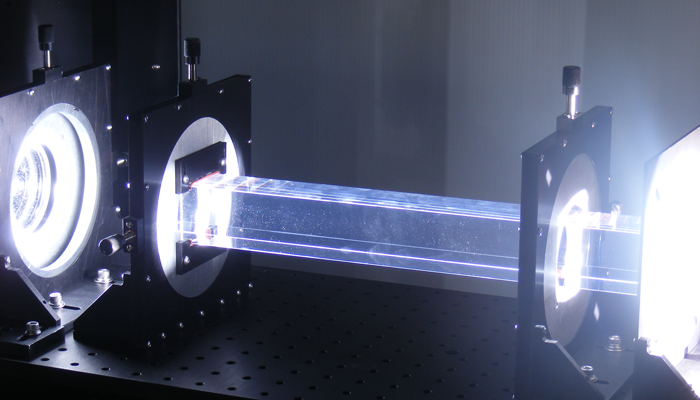

Sciencetech designs and manufactures optical spectroscopic instruments, which are utilized across a wide range of industries and applications.

OZ Optics Ltd.

OZ Optics designs and manufactures advanced fiber optic components and test equipment for various fiber optic markets. The company implements rigorous quality standards to achieve its goal of providing all customers with a competitive advantage, and has become a leading worldwide supplier of optic products.

Parsons ADL

Located in New Tecumseth, Ontario, Parsons ADL is a manufacturer of home health care products. The company strives to create innovative solutions that will help improve the quality of life for the ageing population, as well as individuals with disabilities.

RBR Ltd.

RBR designs and manufactures innovative oceanographic instruments that satisfy customer budgets and applications. The company offers sensors capable of tracking various water parameters, data loggers, and a variety of accessories for its products.

Kinarm

Kinarm is transforming the assessment of brain injuries by putting cutting-edge robotics technology into the hands of neuroscientists and clinician-scientists around the world.