-

Headquarters -

63 Regent Park Blvd, Toronto, Ontario, M5A 2B7

-

Year established -

2015

-

NAICS -

315990 - Clothing accessories and other clothing manufacturing

-

Major expansions -

N/A

-

Employees -

16

-

Exports -

N/A

-

Download -

George Brown College Fashion Exchange

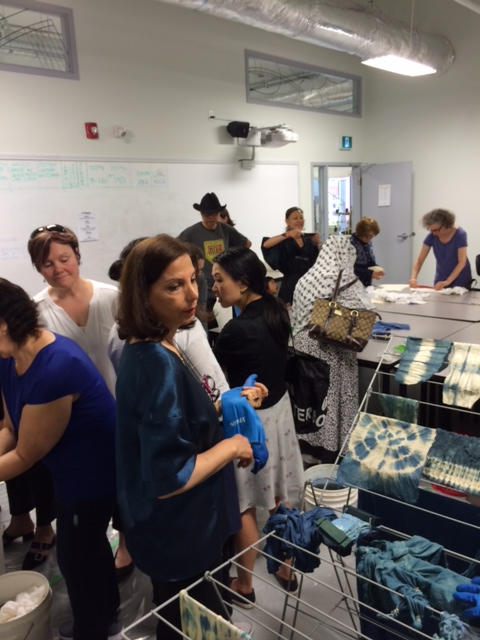

College’s Fashion Exchange (GBFX) fosters collaboration between fashion educators, industry partners, community organizations, and fashion graduates.

Located in Regent Park, Toronto, Ontario, George Brown College’s Fashion Exchange (GBFX) fosters collaboration between fashion educators, industry partners, community organizations, and fashion graduates. Through these collaborations, GBFX aims to develop a sustainable, socially conscious, and economical fashion industry. The organization has become a key part of the fashion industry in Ontario for two main reasons. First, due to the lack of available talent in Ontario within the apparel industry, GBFX is continuously developing qualified graduates who have practical experience and can immediately enter the workforce. Second, most small and medium-sized local fashion companies are unable to find contractors willing to manufacture products in smaller order quantities. GBFX partners with these companies to manufacture small runs of their products at a fair price, helping firms move past the initial stages of growth.

GBFX’s journey began in December 2013, when George Brown College (GBC) first submitted an application for the Fashion Exchange to the Ontario Government’s Youth Skills Connections (YSC) Industry Stream grant. In April of the following year, 29 fashion industry partners in the Greater Toronto Area provided letters of support for the project, which was approved in December 2014. The Fashion Exchange immediately developed an Apparel Fit Technician curriculum and an Industrial Power Sewing curriculum, which allowed the first cohort of YSC-funded students to begin their education. After two cohorts graduated from these programs and the project’s facility underwent renovations, GBFX had its grand opening at 63 Regent Park Boulevard in March 2016. Over the next two years, Shahrzad Sadeghi (Community Engagement Manager), Gagan Singh (Facility & Production Manager), and Marilyn McNeil-Morin (Director) joined the organization. All three assisted with the rapid developments happening at GBFX, including another undergraduate curriculum, two graduate programs, multiple successful grant applications, various industry partnerships, and over 60 successfully completed client purchase orders.

Women in Fashion Technology is a third fast-track undergraduate curriculum that GBFX recently began offering. All three curricula are unique and teach students distinctive sets of skills, some of which include apparel fitting techniques, garment construction, elements and construction techniques for section and semi-section work, multiple component assembly techniques, and knowledge about the latest technology in apparel manufacturing. Examples of the many positions available to students upon graduation include line supervisor, cutting helper, fitting technician, product development assistant, and specialized machine operator in dye sublimation printing. For individuals who wish to continue their education in the fashion and apparel industry, GBFX also offers two three-semester graduate programs: Sustainable Fashion Production and Apparel Technical Design. Graduates are prepared for positions requiring expertise in the apparel production process, quality control, and sustainable fashion development thanks to a wide variety of capabilities, such as the ability to manage the manufacturing process of small batch apparel products, make decisions regarding optimal sustainable product development and manufacturing, and perform market analysis and trend research on the apparel industry.

GBFX prides itself on creating curricula that give students the necessary and applicable skills and qualifications to quickly obtain employment and become productive in the fashion industry. Along with the course-specific learning outcome requirements, students are given essential transferable skills such as communication, resume preparation, interview, problem solving, and interpersonal skills, as well as information on customer service standards. Each fast-track undergraduate program also includes a work placement, providing students with 100–280 hours of industry experience. Arguably the greatest benefit of all three fast-track undergraduate programs is that, due to the grants received by GBFX, they are offered at no cost to students who have their online application accepted.

In addition to offering students a practical education, GBFX offers the Ontario apparel industry invaluable sample making and small production services. GBFX operates on a cost-recovery basis, so it is able to offer smaller local fashion companies affordable prices while refraining from undercutting local manufacturers. All employees hired to manufacture client orders are experienced professionals rather than students, allowing GBFX to produce high-quality products and retain its many satisfied customers.

GBFX utilizes a lean production system, with machinery placed on tables that are easy to move and cords plugged into outlets on the ceiling, allowing production cells to be easily adapted to new projects and new products. This lean production setup facilitates efficient small batch production, enabling many emerging designers and local brands to build their businesses. Consistently taking on new projects also keeps GBFX’s multi-skilled employees engaged and excited because they are never working on the same product for too long.

Customers value the honesty and transparency exhibited by GBFX, and report that they always feel in control of their own products and how they are made. A portion of GBFX’s customers are firms who previously attempted to outsource production to cut costs, but were unhappy with the experience. GBFX ensures that the client is constantly involved in the design and production process, offering mentorship and training services along the way. Indeed, the organization’s mentorship program gives clients the option of being paired with fashion industry experts who are available to guide, assist, and advise them based on their business goals and design concepts. Custom training workshops are designed to focus on specific fashion industry issues, helping new designers develop, improve, and learn the skills necessary to successfully bring ideas to market. This breadth of knowledge and experience at GBFX is another aspect that is highly valued by customers.

GBFX has been so successful that even though it does not actively engage in marketing, word-of-mouth referrals continue to result in increased demand for its manufacturing services. However, one recent challenge that GBFX successfully overcame was its development of a manufacturing services operation. Recognizing the need for a facility that could provide small-batch manufacturing services, Marilyn McNeil-Morin approached GBC with a proposal to offer these services. Although GBC was initially reluctant to agree to this expansion, McNeil-Morin highlighted the benefits that it would provide to the apparel industry and the positive impact it would have on GBC.

Although GBFX is already well-integrated within its community due to the positive relationships it has built with local fashion companies, the organization is planning to become even more involved. A project called “Hidden Talents” is currently being developed to help GBFX achieve this goal. GBFX recognizes that many immigrants in Canada possess various textile hand-skills that were taught to them as part of their cultural identity, whether it was to embellish clothing, decorate ceremonial items, or enhance items in the home. The purpose of this new initiative is to prevent these specialized hand-skills from being overlooked and forgotten, ensuring that they are instead handed down and preserved across generations. Hidden Talents aims to develop an exhibition, event, and online portal to showcase the work of multiple artisans in this regard, and connect designers directly to these artisans for future employment. Additionally, quarterly workshops where artisans can share their skills will assist with community development and foster an appreciation for unique textile hand-skills among other cultures.

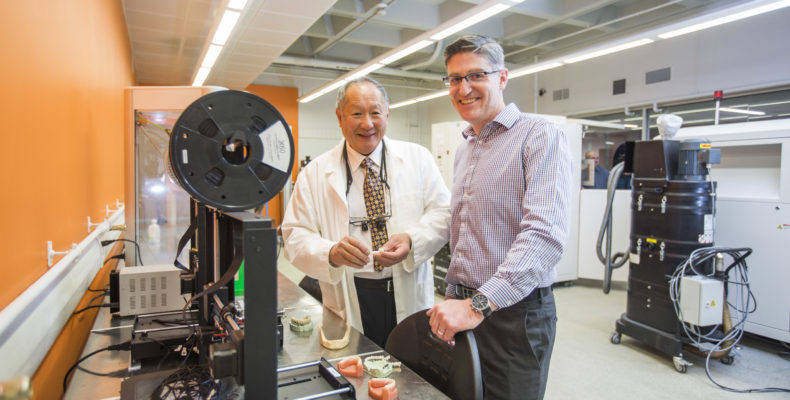

Moving forward, GBFX plans to capitalize on the research funding it was recently granted by investing in new equipment, actively looking for collaborative research projects, and searching for the most efficient uses of technology within the apparel industry. McNeil-Morin is well aware of the benefits that adopting technology can provide, and ensures that GBFX stays current in this respect. For example, GBFX digitizes patterns because it is significantly easier to adjust, update, and recall digital patterns. Further, the organization’s use of virtual prototyping and 3D body scanning results in accuracy improvements by eliminating human error. Recent investments include a laser cutter with built-in technology for embroidery and a waterless printer for dye supplementation printing. McNeil-Morin has noticed that firms in the industry are often slow to adapt to new technology because of the lack of awareness surrounding the full potential of the new equipment. GBFX plans to address this issue by showing clients first-hand that adopting new technologies will facilitate financial, social, and environmental sustainability and allow clients to compete more effectively in the Canadian apparel sector.

For more information about George Brown College Fashion Exchange, visit their website.

Published: August 12, 2019

Southern Ontario Network for Advanced Manufacturing Innovation

The Southern Ontario Network for Advanced Manufacturing Innovation (SONAMI) is a network of post-secondary research institutions that have come together, in an effort to grow the quality and quantity of applied research innovation in the Southern Ontario advanced manufacturing cluster.

Kinarm

Kinarm is transforming the assessment of brain injuries by putting cutting-edge robotics technology into the hands of neuroscientists and clinician-scientists around the world.

Siemens Canada Engineering and Technology Academy (SCETA)

The Siemens Canada Engineering and Technology Academy (SCETA) is a unique initiative designed to equip engineering and engineering technology students in Canada, and Siemens’ own engineers, with the educational and professional foundation required for successful careers. The goal of the Work Integrated Learning Program (WILP) is to educate post-secondary students on Industry 4.0 concepts such as electrification, automation, digitalization and cloud technology.

Fanshawe College

Fanshawe’s School of Applied Science and Technology emphasizes the technical skills required for workplace productivity.

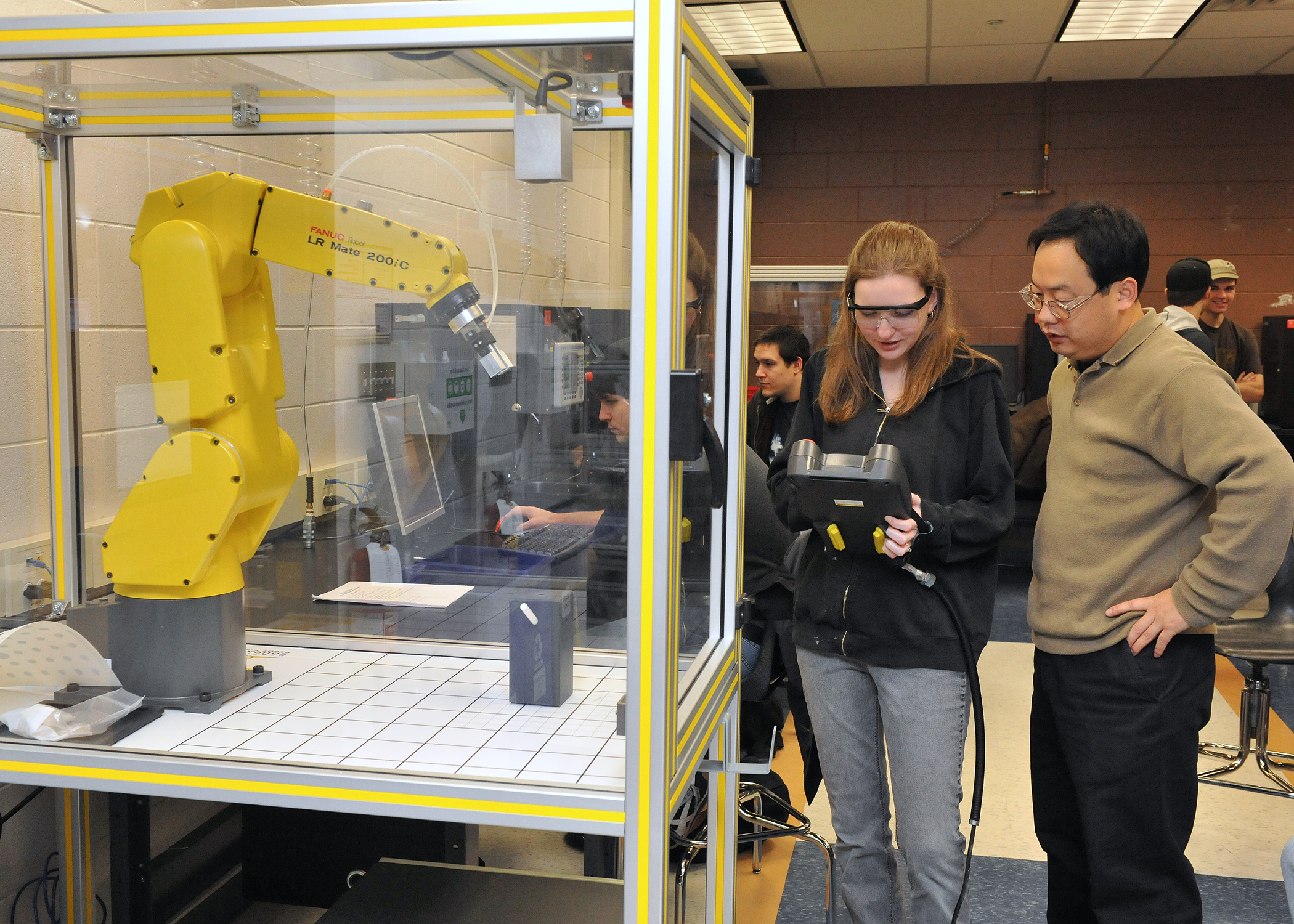

FIRST Robotics Canada

FIRST Robotics Canada is a registered charity that connects elementary and high school students with businesses and post-secondary educational institutions by organizing and coordinating robot-building and robo-sport competitions.